What is Fabric Glue? Uses, Types & No-Sew Bonding Guide

For small clothing business owners juggling design, production, and repairs, efficiency is key. Tasks like fixing minor tears, attaching embellishments without intricate sewing, or quickly adjusting hems demand practical solutions. This is where understanding fabric glue becomes essential.

These specialized bonding agents offer a valuable no-sew solution for various clothing tasks, potentially saving time and simplifying certain processes. This guide explores the world of fabric glue, comparing it to traditional sewing thread alternatives, examining different types, and offering insights into selection, application, and troubleshooting for various textiles.

Knowing when and how to use fabric glue effectively can help achieve professional results, prevent damage to garments, and streamline certain aspects of your workflow, especially for quick repairs.

1. Unpacking fabric glue: The basics for your business

1.1 What exactly is fabric glue?

Fabric glue, also known as a textile adhesive, is a type of liquid adhesive specifically formulated to create a bond between layers of fabric or other textiles. Its primary purpose is to join materials without the need for stitches.

Think of it as a specialized tool within the broader category of adhesives, engineered to work effectively with the unique properties of fibers and weaves found in clothing and other textile products. It facilitates bonding fabrics securely for repairs, decorations, or construction in specific applications.

1.2 Beyond sticking: Key characteristics

What makes fabric glue suitable for clothing applications are several key properties:

- Flexibility: A crucial characteristic is that a good flexible adhesive remains pliable after drying. This allows the glued area to move and bend with the fabric, preventing stiffness or cracking during wear.

- Bond strength: Fabric glues offer varying levels of bond strength. Some provide a temporary hold, ideal for positioning elements before sewing, while others create a permanent bond designed to withstand significant stress and use.

- Washability: Many formulas are designed to be washable, meaning they can endure machine washing and drying cycles *after* the glue has fully cured (hardened completely according to instructions). This is vital for garment longevity.

- Clear drying: Most quality fabric glues dry transparent (clear drying), making the bond nearly invisible and preserving the aesthetic of the garment.

2. Fabric glue vs. sewing: Making the right choice

While sewing remains the foundation of garment construction, fabric glue offers distinct advantages in certain scenarios. Understanding when to reach for the glue bottle versus the needle and thread is crucial for efficiency and appropriate application.

2.1 Speed and convenience: When glue outpaces the needle

One of the most significant benefits of fabric glue is time efficiency. For quick repairs, like securing a loose hem, fixing a small tear away from a high-stress area, or attaching lightweight embellishments, applying glue is often much faster than setting up a sewing machine or meticulously hand-stitching. This makes it an invaluable tool for rapidly mending materials when deadlines are tight or the fix is minor. It serves as a practical alternative to sewing for specific, time-sensitive tasks.

2.2 Accessibility: The value of a no-sew solution

Fabric glue provides remarkable accessibility. Unlike sewing, which requires specific sewing skills and equipment (like needles, thread, and potentially a machine), using fabric glue is straightforward. This makes fabric repairs and certain creative projects achievable for anyone on your team, regardless of their sewing expertise, offering a true no-sew solution for designated applications.

2.3 Versatility in application: Quick repairs, attaching embellishments, and more

The versatility of fabric glue extends to numerous applications relevant to clothing businesses. Beyond basic repairs like hemming or patching small holes, it’s also excellent for various craft applications. It’s effective for securely attaching patches, applying decorative embellishments like beads or sequins, affixing trims and ribbons, or even temporarily basting pieces together during the design phase.

2.4 Understanding the limits: When sewing is non-negotiable

It’s critical to recognize the limitations of fabric glue. Sewing, with its interlocking stitches formed by sewing thread, provides structural integrity that glue cannot replicate in all situations. Fabric glue is generally *not* suitable for:

- Structural seams: subject to high stress (e.g., crotch seams, armholes, load-bearing connections).

- Primary garment construction: where strength and long-term durability under tension are paramount.

- Very heavy fabrics: that will be under constant strain.

- Applications where a specific stitched aesthetic is desired

Fabric glue is a valuable tool for specific jobs, but it does not universally replace the strength and resilience of traditional sewing for core garment structure.

Not all fabric glues are created equal. Different formulations cater to specific needs, from permanent bonds to temporary holds. Understanding the types helps in selecting the right product for the task.

3.1 Permanent fabric glues: For bonds that last through wear and wash

Permanent fabric glue is engineered to create a durable bond intended to last the lifespan of the garment. These adhesives are typically washable and resistant to wear and tear once fully cured. They are the go-to choice for tasks like applying permanent patches, reinforcing weakened areas prone to tearing, securing long-lasting embellishments, and performing durable fabric repair where sewing isn’t practical or desired. The focus here is on creating a long-lasting connection.

3.2 Temporary fabric glues: Ideal for positioning, basting, and adjustments

Temporary fabric glue serves a different purpose. Its bond is designed to be short-term, making it perfect for positioning appliqué pieces, aligning patterns, or holding seams together for basting before final stitching. Some temporary formulas are designed to wash out completely, while others allow for repositionable adjustments shortly after application. This type offers convenience during the construction or adjustments phase without creating a permanent bond.

3.3 Specialized formulas: Exploring heat-activated, spray, and flexible adhesives

Beyond permanent and temporary, several specialized adhesive types exist:

- Heat-activated adhesive: These require heat, usually from an iron, to create the bond. Hemming tape and some iron-on patches are common examples.

- Spray adhesive: Delivered via an aerosol can, spray adhesive is useful for covering larger fabric surfaces quickly. It’s often used for temporary bonding in quilting or pattern placement.

- Highly flexible adhesive: Certain formulas are specifically marketed as extra flexible adhesive, designed for use on stretchy fabrics like knits or Lycra blends, where maximum movement is required without compromising the bond.

Fabric glue types comparison

| Type | Activation/Application | Best Use Case |

|---|---|---|

| Heat-activated | Heat (Iron/Press) | Hemming tape, iron-on patches, appliqué |

| Spray adhesive | Aerosol spray | Large area temporary bonding (quilting, patterns) |

| Highly flexible | Liquid application (tube/bottle) | Stretchy fabrics, areas needing maximum movement |

3.4 A quick look at formulations: Water-based (e.g., PVA) vs. solvent-based adhesives

Understanding the basic formulation can inform usage and safety:

- Water-based adhesives: Often utilizing PVA (Polyvinyl Acetate) polymer resins, these glues are typically non-toxic, have low odor, and allow for cleanup with water while still wet. They are common for general fabric gluing.

- Solvent-based adhesives: These may offer stronger bonds or faster drying times but often contain volatile organic compounds (VOCs) requiring good ventilation during use. Cleanup usually requires specific solvents. The polymer resins used might differ to achieve specific bonding properties.

Always check the product label for specific ingredients and safety recommendations.

4. How to choose the right fabric glue for your garments and projects

Selecting the appropriate fabric glue is crucial for successful results. Consider the fabric type, the project’s demands, and practical application factors.

4.1 Matching glue to material: Cotton, polyester, denim, blends, nylon, leather, and delicate textiles

Material compatibility is paramount. While many general-purpose fabric glues work well on natural fibers like cotton, denim, and basic polyester blends, other materials require more specific considerations:

- Synthetic fabrics (nylon, etc.) / leather: These non-porous or smooth surfaces can be challenging. Look for glues specifically formulated for synthetic fabrics or leather, which may offer better adhesion. Some specialized industrial adhesives (like certain polyurethane types) might be needed for difficult bonds, though these often require specific application methods.

- Delicate textiles (silk, lace, sheer fabrics): For these, choose glues that dry exceptionally clear, remain highly flexible, and are specifically designed not to bleed through thin materials. Minimal application is key.

Crucially, *always* test the glue on an unseen scrap or seam allowance of the *exact same* fabric type before applying it to the main garment. This checks for bonding effectiveness, potential discoloration, stiffness, and bleed-through.

4.2 Defining your needs: Wash resistance, required bond strength, and flexibility

Analyze the project requirements. Ask yourself:

- Will the item require frequent washing? If yes, high wash resistance is essential (choose a permanent, washable glue).

- Does the bond need to withstand stress or pulling? Determine the necessary bond strength. For purely decorative elements, less strength might suffice than for a functional repair.

- Is the glued area on a part of the garment that needs to stretch or move? Prioritize flexibility.

Matching these needs to the glue’s properties (e.g., permanent vs. temporary, standard vs. high flexibility) ensures the bond performs as expected.

4.3 Considering application: Ease of use, applicator types, open time, drying time, and curing time

Practical application method factors influence the process:

- Ease of use: Glues vary in viscosity (thickness). Some are thin and runny, others are thicker gels. Choose based on your control preference.

- Applicator types: Fine tip applicators are great for precise detail work, while built-in brushes or separate tools help spread glue evenly over larger areas.

- Open time: This is the window you have to work with the glue and reposition fabrics before it starts setting. Longer open times are helpful for complex placements.

- Drying time: This refers to when the glue becomes tack-free or initially set. It’s *not* the same as full strength.

- Curing time: This is the total time required for the glue to reach its maximum bond strength and stated properties (like washability). This can range from 24 to 72 hours or more. Patience during curing time is vital for durability.

4.4 Prioritizing safety and finish: Seeking non-toxic, low-odor, and non-yellowing options

Especially for clothing worn against the skin or for childrenswear, consider safety considerations. Look for non-toxic labels (like ACMI certification where applicable). Low-odor formulas improve the working environment. For aesthetic longevity, choose non-yellowing glues, particularly for light-colored fabrics, to ensure the bond remains invisible over time. Always read safety data sheets if available for commercial products.

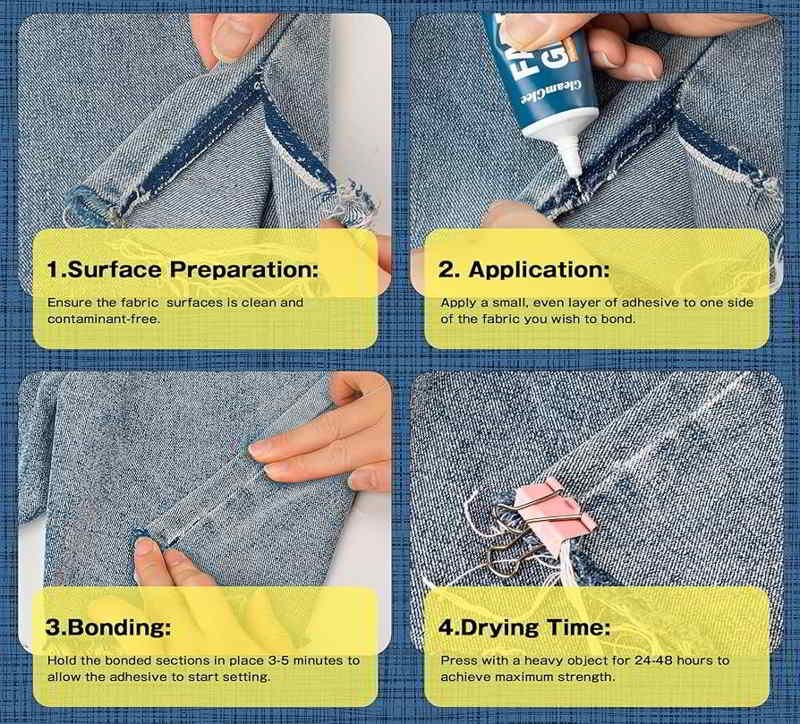

5. Mastering the application: A step-by-step guide

Proper application technique is just as important as choosing the right glue. Following best practices ensures a strong, clean, and durable bond.

5.1 Getting started: Fabric preparation and testing

Before applying any glue:

- Fabric preparation: Ensure the fabric surfaces are completely clean and dry. Pre-washing the garment (without fabric softener, which can interfere with adhesion) is recommended if possible. Dirt, oils, or finishes can prevent a good bond.

- Testing: This step is non-negotiable. Always test the chosen fabric glue on an inconspicuous area – a hidden seam allowance, an inside facing, or a scrap of the identical fabric. Check for bond strength after curing, any visual changes like darkening or shininess, bleed-through, and stiffness. This prevents costly mistakes on the final item.

5.2 Applying the adhesive: Best practices for a clean, even bond

Follow these application tips for optimal results:

- Apply a thin, even layer of glue. Using too much can cause stiffness, longer drying times, and potential bleed-through. Less is often more.

- Typically, apply the glue to only one of the surfaces being joined, unless the product instructions specify otherwise.

- Use the applicator tip or a small tool (like a toothpick, small brush, or plastic spreader) to ensure the glue is distributed evenly. Avoid large blobs or thick lines.

- Work efficiently within the glue’s specified “open time” to position the fabric pieces correctly before the glue starts to set. Aim for an even bond across the entire area.

5.3 The waiting game: Understanding drying vs. full curing for optimal results

It’s crucial to differentiate between drying time and curing time:

- Drying time: This is when the glue feels dry to the touch or becomes tack-free. The initial bond is formed, but it hasn’t reached maximum strength.

- Curing time: This is the period required for the chemical process within the adhesive to complete, achieving its full bond strength and properties like washability or heat resistance. This often takes 24-72 hours, sometimes longer depending on the glue, fabric, and environmental conditions (humidity, temperature).

Resist the temptation to wash or heavily stress the glued item until the full cure time specified by the manufacturer has passed. Patience ensures durability.

5.4 Pro tip: Clamping, pinning, or using tape for secure adhesion

To ensure firm contact between the fabric layers while the glue sets and cures, consider clamping, pinning, or using tape.

- Small craft clamps or binder clips work well along edges or hems.

- Pins can be used, but place them just *outside* the glued area if possible to avoid creating holes in the bond.

- Low-tack painter’s tape can gently hold pieces flat and in place.

Applying pressure helps create a stronger, more secure adhesion, especially on thicker fabrics or when gluing larger areas. This is a key part of the bonding process.

6. Practical applications in the apparel world

Fabric glue can be integrated into various stages of apparel production and maintenance, offering efficient solutions for specific challenges.

6.1 Efficient fixes: Hemming, minor seam repairs, and patch application

For everyday clothing repairs, fabric glue shines. It allows for quick hemming adjustments without sewing, reinforcing small openings in seams (away from high-stress points), and securely attaching fabric patches for both repair and decoration. These applications leverage the glue’s speed and ease of use for mending clothes efficiently.

6.2 Adding flair: Attaching embellishments, trims, and decorative elements

Fabric glue acts as an effective craft glue for adding decorative details. Use it to attach embellishments like beads, sequins, rhinestones, studs, lace trims, ribbons, or other decorative elements. This is often faster and less visible than stitching for certain applications, particularly when attaching patches or small, intricate pieces. Always ensure the glue is compatible with both the fabric and the embellishment material.

6.3 Streamlining prototypes: Temporary holds for sample making

In the design process, *temporary* fabric glue can be a valuable tool for sample making. Use it to quickly assemble prototypes or hold pieces like pockets or collars in place for fitting and visualization before committing to final stitching. This allows for faster iteration and adjustment during development.

Using fabric glue for primary brand or care labels and tags requires careful consideration. While it *might* seem like a quick solution, there are significant potential drawbacks:

- Bleed-through: Glue can seep through thin label materials or the garment fabric, creating visible marks.

- Stiffness: The glued area might become stiff and uncomfortable against the skin.

- Durability: Glued labels may not withstand repeated washability cycles as well as sewn-in labels, potentially detaching over time.

- Ink interaction: Glues could potentially react with inks used on labels.

Sewing remains the industry standard and most reliable method for attaching essential care and brand labels. While glue *might* be feasible for temporary event tags or perhaps some decorative patch-style labels (made from sturdy fabric), rigorous testing on the exact label material and garment fabric is absolutely essential before considering it for permanent branding. Manage expectations – glue is generally not the best practice for critical labeling due to durability and aesthetic considerations.

7. Troubleshooting and best practices

Even with careful application, issues can sometimes arise. Knowing how to troubleshoot common problems and reinforce best practices helps ensure consistently good results.

7.1 Oops! How to handle and remove unwanted fabric glue

Accidents happen. How to remove fabric glue depends on the glue type and whether it’s wet or dry:

- Wet water-based glue: Often cleans up easily with soap and water. Act quickly before it dries.

- Wet solvent-based glue: May require specific solvents mentioned by the manufacturer (like acetone or rubbing alcohol). *Caution:* Always test the solvent on a hidden fabric area first, as it can damage or discolor some materials. Work in a well-ventilated area.

- Dried/cured glue: This is much harder to remove. Options include soaking the area (if fabric permits), gently scraping with a dull edge (very carefully to avoid fabric damage), or using specialized adhesive removers. Again, test removers first. Sometimes, complete removal is impossible without affecting the fabric. Following manufacturer advice for removal is always the best starting point for troubleshooting.

7.2 Ensuring durability: Tips for a strong, long-lasting bond

To maximize the durability of your glued bond:

- Choose the correct glue type for the fabric and intended use.

- Ensure fabric is clean, dry, and free of finishes.

- Apply a thin, even layer – avoid excess glue.

- Apply sufficient, even pressure (clamping/pinning) while setting.

Critically, allow the glue to achieve its full cure time before washing, wearing, or stressing the bond. Rushing this step is a common cause of bond failure. Following these best practices significantly improves the chances of a long-lasting bond.

7.3 Working with challenging materials

Gluing certain fabrics requires extra care:

- Synthetic fabrics/non-porous: Besides using specialized glue, lightly roughening the surface (if possible without damage) can sometimes improve adhesion. Test thoroughly.

- Heavy fabrics (denim, canvas): Ensure adequate glue coverage and apply firm, sustained pressure during curing. A longer curing time might be beneficial.

- Delicate fabrics/sheers: Use the absolute minimum amount of glue specifically designed for lightweights. Test extensively for bleed-through and ensure the glue dries clear and flexible. Consider applicators with very fine tips.

These tips help navigate common issues with challenging materials like synthetic fabrics, heavy fabrics, and delicate fabrics.

7.4 Common mistakes to avoid

Be mindful of these frequent errors in troubleshooting and practice:

- Using too much glue: Leads to stiffness, longer drying/curing, potential bleed-through, and a weaker bond overall.

- Not allowing full cure time: Washing or stressing the bond before it’s fully cured is a primary reason for failure.

- Choosing the wrong glue type: Using temporary glue for permanent needs, or glue not compatible with the fabric.

- Inadequate fabric preparation: Gluing dirty, damp, or chemically treated fabric will likely result in a poor bond.

Being aware of these potential pitfalls helps avoid errors and achieve better outcomes.

8. Safety considerations when using fabric adhesives

Working with any chemical product requires attention to safety. Fabric glues are no exception.

8.1 Proper ventilation and personal protection

Always work in a well-ventilated area. This is especially important when using solvent-based adhesives, which can release fumes (VOCs). Opening a window or using a fan can help ensure adequate airflow. While many fabric glues are non-toxic, wearing gloves (like nitrile) is a good practice to prevent skin contact, especially if you have sensitivities or are working with stronger formulas. These simple safety considerations contribute to a healthier workspace through ventilation and personal protection.

8.2 Reading and following manufacturer instructions

This is the single most important safety and usage rule. The product label and any accompanying manufacturer instructions contain crucial information specific to that glue, including:

- Recommended fabric types

- Application directions

- Open time, drying time, and *full* curing time

- Specific safety precautions (ventilation, skin/eye contact)

- Cleanup procedures

- Washability and heat resistance details

Always read and adhere to these instructions *before* starting your project. They provide the most accurate guidance for both safety and achieving the best results.

9. Related questions

Here are answers to some frequently asked questions about fabric glue in a clothing context.

9.1 Can fabric glue permanently replace sewing for all clothing tasks?

No, fabric glue cannot permanently replace sewing for all tasks. While excellent for hems, patches, embellishments, and minor repairs, it lacks the inherent strength and flexibility required for structural seams under high stress (like armholes, crotch seams, or side seams on fitted garments). Sewing provides a mechanical lock with thread that glue cannot replicate for load-bearing construction. Think of fabric glue as a valuable complementary tool with specific limitations, not a universal substitute.

9.2 Will fabric glue make the fabric stiff or uncomfortable?

It can make fabric stiff if applied incorrectly. Using too much glue is the most common cause of stiffness. Modern fabric glues are formulated for flexibility, but achieving this depends on applying a thin, even layer. The specific glue formula and the type of fabric also influence the final feel. Testing on a scrap beforehand is the best way to gauge the potential impact on stiff fabric feel.

9.3 How heat resistant is cured fabric glue, especially during ironing?

Heat resistance varies significantly between different fabric glue formulations. Some cured glue types tolerate low to medium ironing heat well, while others may soften, weaken, or even melt under direct heat. Always check the manufacturer’s instructions for specific heat tolerance information. As a general precaution, it’s wise to:

- Iron around heavily glued areas whenever possible.

- Use a pressing cloth between the iron and the fabric.

- Start with a lower iron temperature setting and increase only if necessary and safe according to the glue’s specifications.

Heat-activated adhesives are designed for heat *application* but still have limits on heat exposure once cured.

9.4 Are there eco-friendly or less toxic fabric glue options available?

Yes, options prioritizing lower environmental impact and user safety exist. Many water-based glue formulas, often using PVA (Polyvinyl Acetate), are non-toxic and have low VOC (Volatile Organic Compound) emissions compared to solvent-based alternatives. Look for products explicitly labeled “non-toxic,” check for certifications (like ACMI AP – Approved Product), and review ingredient lists if seeking eco-friendly or minimally toxic options is a priority.

Read more:

Fabric glue offers significant benefits for clothing professionals when used appropriately. It stands out as an efficient tool for specific tasks like quick repairs, hemming adjustments, patch application, and attaching embellishments, providing a valuable alternative or supplement to sewing in these contexts.

The key lies in making an informed choice: selecting the right type of glue for the specific fabric and the demands of the project (permanence, flexibility, washability). Proper workflow integration also hinges on meticulous application – clean surfaces, thin even layers, and crucially, allowing the adhesive to reach its full cure time before subjecting it to stress or washing.

Understood and used correctly, fabric glue is a smart addition to the clothing professional toolkit, saving time and offering creative possibilities. With the fundamentals covered in this guide, you can explore and utilize fabric adhesives more confidently. For specialized advice on choosing the right fabric glue or other adhesive solutions for your specific apparel projects, contact the experts at Packlove.