Iron-On Patches on Tights: High Risk, Safer Alternatives

Customizing clothing allows for unique expression, and adding patches to stocking tights (thin, stretchy legwear often made of nylon or similar synthetics) is one way individuals and businesses seek to personalize garments. However, attempting to use standard ironing patches presents significant challenges and a high-risk of damaging these delicate fabrics.

This guide explores why this method is problematic, outlines a cautious (though not recommended) procedure for those determined to try, and details much safer alternatives to achieve durable and attractive results when you want to customize hosiery. Understanding these factors helps protect your garments and achieve professional-looking customization.

1. Why ironing patches on tights is fraught with risk?

Before attempting any patch application method, especially one known for its potential pitfalls like ironing patches onto tights, understanding the underlying reasons for the difficulty is crucial. Several factors conspire to make this a particularly problematic endeavor, primarily involving material sensitivity to heat, the nature of patch adhesives, and the inherent stretchiness of the fabric.

1.1 Material matters: The extreme heat sensitivity of nylon and spandex

The core issue lies in the materials typically used for stocking tights or general hosiery. Most are crafted from nylon, spandex (also known as Lycra or elastane), or blends of these synthetic materials. A synthetic materials warning is pertinent here: these fibers possess very low melting points compared to robust fabrics like cotton or denim.

Direct contact with the heat levels required by many iron-on patches can cause immediate and irreversible fabric damage. This damage risk manifests in several ways:

- Melting: The fibers literally melt, creating hard, brittle spots or outright holes.

- Shine/stiffness: Even if not fully melting, excessive heat can alter the fabric’s texture, leaving shiny patches or making the area stiff and uncomfortable.

- Weakening: Heat stress can compromise the integrity of the fine fibers, making the tights prone to runs or tears later.

This pronounced heat sensitivity makes standard ironing techniques unsuitable for these delicate fabrics.

1.2 Understanding iron-on patch adhesive and heat requirements

Iron-on patch designs typically feature a backing coated with a heat-activated adhesive, often a type of plastic or resin. This adhesive bonding process requires a specific temperature range, maintained for a certain duration, for the adhesive to properly melt, flow into the fabric fibers, and create a secure bond as it activates.

Unfortunately, the necessary heat requirements for most standard iron-on adhesives significantly exceed the safe temperature threshold for the nylon and spandex fibers found in delicate fabrics like tights. Applying sufficient heat to activate the glue almost guarantees damage to the underlying hosiery.

1.3 The stretch factor: Adhesion issues on elastic stocking tights

Beyond heat sensitivity, the very nature of stocking tights – their high elasticity or stretch factor – presents another significant hurdle for patch application. Hosiery is designed to stretch considerably when worn. If a relatively rigid patch is applied using adhesive bonding while the stretch fabric is relaxed (unstretched), problems arise when the garment is put on:

- Puckering/warping: As the elastic fabric stretches around the leg, the area under and around the inflexible patch can bunch up or distort.

- Adhesion failure: The adhesive bonding itself might not be flexible enough to accommodate the stretch. This stress can cause the patch edges to lift, peel, or detach completely. Effective hosiery care considers how the garment functions when worn.

2. Attempting the impossible? A cautious protocol for ironing patches on tights

Disclaimer: This method is not recommended due to the extremely high risk of irreparable damage to your stocking tights. The following cautious protocol is provided solely for informational purposes for those who understand these risks and still wish to attempt application, fully accepting the strong possibility of failure and ruined garments. Proceed with extreme care and maintain low expectations for success and durability.

2.1 Essential preparation: Tools for damage mitigation

Gathering the correct tools is critical for even attempting this risky procedure, focusing on fabric protection and damage mitigation:

- Iron: Must possess reliable and accurate low temperature settings, specifically a synthetic or silk setting. Do not use an iron without these precise controls.

- Pressing cloth: A thick, clean piece of cotton fabric (like a handkerchief or scrap from quilting) is essential. Alternatively, a Teflon sheet (often used in heat pressing) offers excellent non-stick protection. This layer shields the tights from direct contact with the iron’s soleplate.

- Hard, flat, heat-resistant surface: A standard ironing board provides the necessary support.

- Iron-on patch: Select the lightest weight, most flexible iron-on patch possible. Stiff or thick patches will exacerbate puckering issues.

- Stocking tights: The garment to be customized. Practice on an old or damaged pair first if possible.

2.2 Step-by-step low temperature application

Precision and minimal heat application are paramount. A synthetic materials warning applies throughout: any overheating risks melting. Always perform a heat sensitivity test on an inconspicuous inner area of the tights first, using the iron and pressing cloth for a couple of seconds to check for damage.

- Set iron temperature: Select the absolute lowest heat setting available (synthetic/silk). Ensure the steam function is OFF.

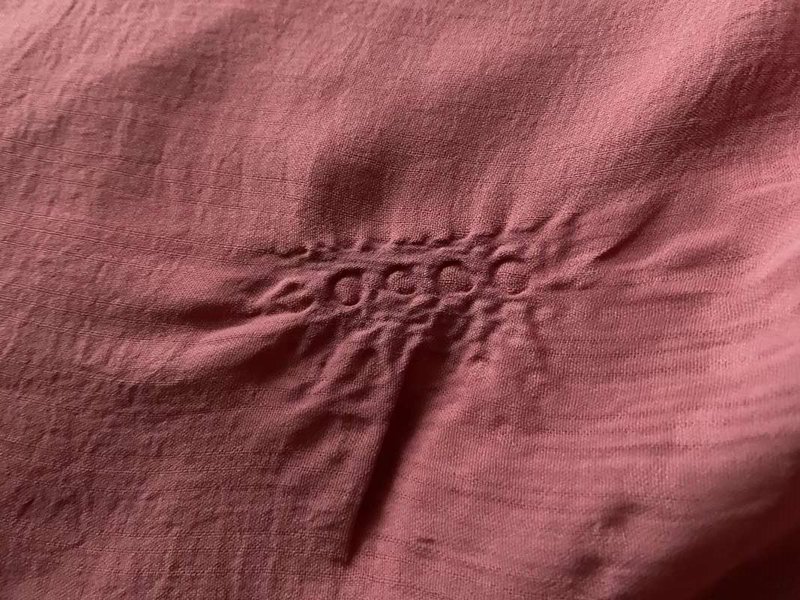

- Prepare tights: Lay the tights flat on the ironing board, smoothing out the target area.

- Position patch: Place the iron-on patch adhesive-side down onto the tights in the desired location.

- Apply protective layer: Cover the patch and surrounding tights area completely with the thick pressing cloth or Teflon sheet. This protective layer is non-negotiable.

- Apply minimal heat & pressure: Press the preheated iron onto the pressing cloth over the patch area. Use minimal pressure. Apply heat in short bursts – literally for only 2-4 seconds at a time. Lift the iron completely between bursts. Do not hold the iron down or move back and forth. The goal is minimal heat application.

- Check adhesion carefully: After one or two short bursts, lift the pressing cloth and carefully check if the patch edges are starting to adhere. Avoid excessive handling while warm.

- Allow cooling: Let the area cool completely before further checks or handling. Heat makes the fibers more vulnerable.

- Repeat if necessary (extreme caution): If adhesion hasn’t occurred, you might attempt one more very short burst of heat. However, repeated applications significantly increase the damage risk. Recognize that adhesive failure is highly likely with this method even if the fabric isn’t immediately damaged.

2.3 Recognizing failure: Signs of heat damage

Immediate cessation of the process is necessary if any signs of heat damage appear. Look closely for:

- Shiny spots: The fabric develops a sheen where fibers have begun to melt.

- Stiffening: The area under or around the patch feels harder or less flexible than the surrounding fabric.

- Thinning/transparency: The fabric becomes noticeably thinner or more see-through, indicating fiber degradation.

- Visible holes: Obvious signs of melting where the fabric has disintegrated.

- Lack of adhesion: Despite careful application, the patch simply fails to stick, indicating either insufficient (but safer) heat or incompatibility.

Any of these signs point towards failure and highlight the inherent melting risk.

3. Recommended ways to attach patches to stocking tights

Given the substantial risks and likely failure associated with ironing, exploring safer methods and more effective patch application methods is highly recommended for attaching patches to stocking tights. These alternatives offer better durability and eliminate the risk of heat damage. Sewing and specialized gluing are the primary recommended ways.

3.1 Hand sewing: The gold standard for durability & flexibility

Hand sewing stands out as the most reliable and recommended method. Why? Because sewing creates a mechanical bond that is both strong and flexible, allowing the patch to move naturally with the stretch fabric of the tights. Crucially, there is zero heat damage risk. For best results:

- Use a fine needle appropriate for delicate fabrics to minimize snagging.

- Choose a strong polyester thread. Matching the patch border color offers a discreet finish, while clear thread is versatile.

- Employ small stitches for security, like a whipstitch (catching the edge of the patch and the fabric beneath) or a hidden running stitch (if the patch construction allows).

- Avoid pulling the thread too tight; allow slight slack so the stitches don’t restrict the fabric’s stretch.

For those involved in creating customized apparel, mastering basic hand sewing is invaluable. This technique aligns with custom apparel business tips focused on delivering high-quality, durable products.

3.2 Using flexible fabric glue: A viable no-sew patch option

For a no-sew patch option, specific types of fabric glue can be effective. The absolute key is selecting an adhesive explicitly labeled as flexible and suitable for stretch fabrics or synthetics. Regular craft glues or rigid fabric glues will crack or peel off when the tights stretch. Look for terms like “stretch,” “flexible,” or “washable fabric adhesive” on the packaging when comparing fabric adhesives.

Before applying to your final garment, always test the chosen fabric glue on a scrap piece of similar material or an inconspicuous area. Check for:

- Flexibility once dry (does it stretch with the fabric?)

- Residue or discoloration

- Bond strength

- Drying time

While generally less durable than sewing over the long term, the right flexible fabric glue offers a much safer alternative to ironing.

3.3 Sew-on velcro: For interchangeable DIY fashion embellishments

For those seeking versatility and interchangeable style, sew-on Velcro (hook and loop fastener tape) provides a clever solution for DIY fashion embellishments. The process involves:

- Securely sewing the soft “loop” side of the Velcro tape onto the tights in the desired location.

- Securely sewing the corresponding rough “hook” side onto the back of your custom patches.

This allows patches to be easily attached, removed, or swapped out. Crucially, use sew-on Velcro, not the adhesive-backed variety. The adhesive on standard Velcro is unlikely to hold reliably on stretchy tights and could potentially damage the delicate fabric or leave residue upon removal.

4. Ensuring quality in hosiery customization for small businesses

For small businesses specializing in apparel, particularly hosiery customization, relying on iron-on patches for stocking tights is generally an unwise strategy. The high potential for damaged inventory during application translates directly to lost revenue. Furthermore, inconsistent results and potential adhesive failure after purchase can negatively impact brand reputation and lead to customer dissatisfaction or returns.

Prioritizing quality and reliability is essential. Sewing patches onto custom tights represents the most professional and dependable approach, ensuring durability that reflects well on your brand. When developing new customized hosiery products, incorporating basic textile testing methods – even simple wash and stretch tests on prototypes – can help identify potential issues early and ensure you select reliable customization methods suitable for the specific fabric and embellishment.

5. Related questions

Here are answers to some common follow-up queries regarding patches on tights.

5.1 Can I use any type of iron-on patch on tights?

While a lightweight, flexible iron-on patch might seem less problematic than a thick, stiff one, the fundamental issue remains the heat sensitivity of the tights themselves. Even lower heat settings required for some patches can still damage nylon or spandex. Therefore, no type of traditional iron-on patch is truly suitable or recommended for direct application to tights due to the fabric’s limitations.

5.2 How do I wash tights after attaching a patch?

Regardless of the attachment method used (sewing, glue, Velcro), the gentlest approach is best for maximizing the lifespan of customized tights. Hand washing in cold water with a mild detergent and allowing them to air dry flat is strongly recommended.

Avoid machine washing and drying, which can stress both the fabric and the attached patch. Patches attached via ironing (if attempted against advice) are likely the least durable through washing cycles.

5.3 What if the iron-on patch starts peeling off my tights?

If an iron-on patch starts peeling, resist the urge to re-iron. Applying more heat again carries a high damage risk to the already stressed fabric. The best course of action is to carefully attempt removal of the patch entirely (if possible without creating holes). Once removed, secure the patch properly using a recommended method like sewing or an appropriate flexible fabric glue.

5.4 Are there patch alternatives for decorating tights?

Yes, there are several patch alternatives for decorating tights and general hosiery. Consider exploring:

- Fabric paints: Look for paints specifically designed for synthetic and stretch fabrics. Always test on an inconspicuous area first to ensure the paint remains flexible after drying and doesn’t crack when stretched.

- Hand embroidery: Careful embroidery using appropriate needles and thread can add intricate designs directly onto the hosiery. This requires skill but offers unique clothing customization.

- Specialized heat transfers: Some companies produce heat transfers specifically formulated for low-temperature application on synthetics. Research these thoroughly and follow manufacturer instructions precisely, always testing first, as risk still exists.

Read more:

In summary, attempting to apply standard iron-on patches directly to stocking tights is an extremely risky endeavor. The inherent heat sensitivity of nylon and spandex fibers makes them highly susceptible to melting and damage from the heat required by most patch adhesives. While a highly cautious low-heat method exists, failure and damage are probable outcomes.

To protect your garments and achieve durable, attractive results, prioritize the integrity of the delicate fabrics. Far safer customization techniques are available and strongly recommended. Sewing offers the best combination of durability and flexibility, moving with the stretch of the hosiery.

Application with a suitable flexible fabric glue designed for synthetics presents a viable no-sew alternative. Exploring these methods allows for creative clothing customization without compromising the quality or longevity of your stocking tights. Choose the appropriate technique to ensure your customization efforts are successful and lasting.