Recycled Plastic: Definition, Types and Brand Impact

Unsure what is recycled plastic and why it matters for your apparel brand? This guide clarifies the definition, contrasting it with virgin plastics derived from fossil fuels. Discover the environmental imperative: reducing landfill waste, saving energy, and lowering your carbon footprint by using materials like rPET and rLDPE.

Understand the recycling journey, from collection and sorting to creating new feedstock. Learn about common recycled plastics in packaging (poly mailers, tags), the challenges of quality and color, and how to confidently choose and communicate sustainable options to build brand trust and contribute to a circular economy.

1. What exactly is recycled plastic?

1.1 Defining recycled plastic vs. virgin plastic

At its core, recycled plastic is material recovered from existing plastic waste – items that have served their initial purpose and have been collected for reprocessing. Think of used bottles, containers, or packaging films being given a new life. In contrast, virgin plastic is brand new material produced directly from raw petrochemical fossil fuels, primarily oil and natural gas.

Creating virgin plastic requires extracting and processing these finite resources. Opting for recycled plastic helps divert waste from landfills and the environment, reducing the demand for new resource extraction and the energy associated with it. The recycled plastic definition centers on reclaiming and reusing materials already in circulation.

1.2 Where does it come from?

Recycled plastic generally falls into two main categories based on its origin:

- Post-consumer recycled (PCR) material: This comes from plastic waste items that have been used by consumers and then discarded for recycling. Common examples include empty water or soda bottles, milk jugs, shampoo containers, and used packaging collected through curbside programs or drop-off centers. Using PCR content directly tackles the plastic waste problem by finding value in items that might otherwise end up in landfills or polluting ecosystems.

- Post-industrial recycled (PIR) material (also known as pre-consumer): This type originates from scrap generated during manufacturing processes before a product ever reaches the consumer. Examples include trimmings, rejects, or overruns from a factory floor. While PIR helps reduce manufacturing waste, post-consumer recycled material often carries greater environmental weight because it addresses the challenge of managing products after consumer use.

1.3 Why the distinction matters for your brand image

Choosing packaging materials isn’t just a logistical decision; it’s a statement about your brand’s values. Incorporating recycled plastics, particularly those with post-consumer recycled (PCR) content, clearly signals a commitment to sustainability practices. It demonstrates your brand is actively working to reduce reliance on virgin plastic and contribute to addressing the global plastic waste problem.

This resonates powerfully with environmentally aware consumers, fostering trustworthiness and potentially influencing purchasing decisions. Being transparent about the type and percentage of recycled content used in your packaging further strengthens this message, showing authenticity in your environmental efforts compared to brands relying solely on new materials derived from fossil fuels.

2. The environmental imperative: Why using recycled plastic is crucial

2.1 Reducing our reliance on fossil fuels

The production of virgin plastic is fundamentally tied to non-renewable resources, relying heavily on fossil fuels like petroleum and natural gas as its primary raw materials. Each new piece of virgin plastic necessitates further extraction of these finite resources. Utilizing recycled plastic fundamentally disrupts this cycle.

By using collected plastic waste as the input material, or feedstock, for new products, the direct demand for extracting virgin fossil fuels is lessened. This shift represents a significant environmental benefit by conserving irreplaceable natural resources.

2.2 Significant energy savings in manufacturing

Manufacturing products from recycled materials typically demands considerably less energy compared to producing them from scratch using raw resources. The process of creating virgin plastic involves extracting fossil fuels, refining them, and synthesizing complex polymers (long chains of molecules that make up plastic) – all energy-intensive steps.

In contrast, collecting, sorting, and reprocessing existing plastics bypasses many of these initial stages. For example, producing recycled PET (polyethylene terephthalate – the plastic commonly used for drink bottles) can require up to 75% less energy than making virgin PET.

While exact figures vary by plastic type and recycling method, the energy saving in manufacturing is a consistent and major environmental benefit of using recycled content.

2.3 Keeping plastic waste out of landfills and oceans

The global plastic waste problem is immense. Discarded plastics overwhelm landfills, which have limited capacity, and significant amounts find their way into oceans and natural environments, causing widespread plastic pollution. This pollution harms wildlife, damages ecosystems, and can persist for hundreds of years.

Recycling serves as a critical waste management strategy for combating this issue. By capturing plastic waste and reprocessing it into new materials, recycling directly diverts these items from disposal routes, achieving landfill diversion and reducing the flow of plastics into sensitive ecosystems.

2.4 Lowering the carbon footprint of your packaging

The environmental advantages of using recycled plastic translate directly into climate benefits. Because producing recycled plastic demands less energy (often derived from burning fossil fuels) and bypasses the initial extraction and synthesis associated with virgin plastic, the process generates fewer greenhouse gas emissions.

Consequently, choosing recycled materials for your packaging actively contributes to climate change mitigation. By reducing the energy and resource intensity embedded in your packaging choices, you effectively lower its overall carbon footprint, contributing to a reduced impact on the global climate.

3. The journey of plastic waste: How recycling actually works

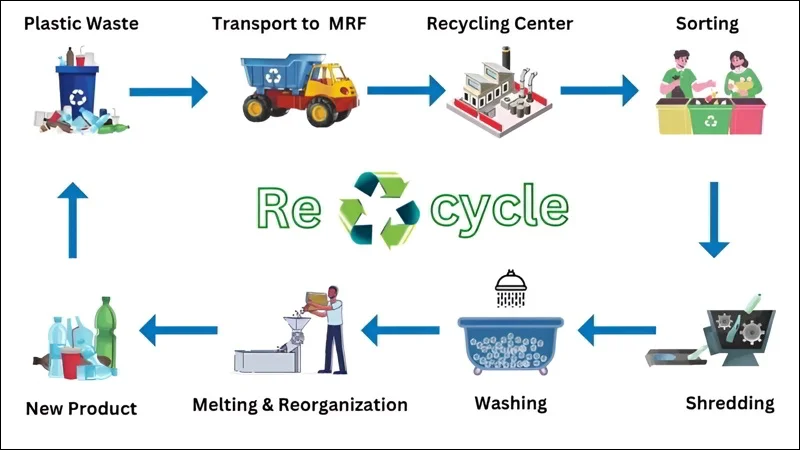

Understanding how that discarded plastic bottle or mailer becomes a new product involves several key stages. The most common method, particularly for packaging, is mechanical recycling.

3.1 Step 1: Collection & transportation

The recycling process begins with gathering the waste materials. This happens through various channels: residential curbside bins, public drop-off centers, commercial collection services that gather waste from businesses, and take-back programs. Once collected, these mixed materials are transported, usually by truck, to a specialized facility known as a materials recovery facility (MRF) or a dedicated sorting center.

3.2 Step 2: Sorting – the critical stage

Sorting is arguably the most crucial step in mechanical recycling methods, as it separates the valuable plastics from other recyclables (like paper or metal) and, importantly, separates different types of plastic from each other. Facilities use a combination of techniques:

- Manual sorting: Workers physically remove obvious contaminants or non-recyclable items.

- Automated sorting: Machines employ various technologies. Screens might separate materials by size, magnets remove ferrous metals, eddy currents repel aluminum, and density separators (using air or water) can help distinguish some plastics.

- Advanced sensor-based separation: Sophisticated systems, often using near-infrared (NIR) light, can identify the specific polymer type by how it reflects light. This allows for accurate separation of common packaging plastics like PET (polyethylene terephthalate, code 1), HDPE (high-density polyethylene, code 2), LDPE (low-density polyethylene, code 4), and PP (polypropylene, code 5), often identified by their resin identification codes (RICs) – the numbers within the chasing arrows symbol. Color sorting may also occur at this stage, using optical sensors to separate clear or light plastics from colored ones, as color affects the final appearance and usability of the recycled material. Accurate sorting is vital for producing a high-quality recycled feedstock.

3.3 Step 3: Cleaning and initial processing

Once sorted by type, the plastics undergo a thorough cleaning process. This typically involves washing cycles to remove contamination such as dirt, food residue, glue, labels, and other unwanted materials. Effective cleaning is essential for the quality of the final recycled plastic.

After washing and drying, the clean plastic items are usually shredded or ground down into much smaller, uniform pieces called flakes or regrind. This size reduction prepares the material for the next stage. This cleaning and size reduction are key parts of mechanical recycling.

3.4 Step 4: Melting, pelletizing & creating new feedstock

The clean, dry flakes are then melted down under controlled temperatures. The molten plastic is filtered to remove any remaining impurities and then extruded (pushed through a die) into long strands resembling spaghetti.

These strands are cooled, often in water, and then cut into small, uniform pellets or granules. These pellets represent the final output of the plastic recycling process at the recycling facility. They serve as the raw material, or feedstock, that manufacturers purchase to create new products containing recycled content.

This transformation of waste into usable pellets is the essence of mechanical recycling, providing the building blocks for items like new bottles, fibers, packaging films, or your recycled poly mailers.

4. Not all plastics are created equal: Focus on apparel packaging materials

While many types of plastic exist, only a few dominate the packaging landscape relevant to apparel businesses. Understanding their characteristics and recycled counterparts is key.

4.1 Spotlight on PET (rPET): Versatility and common uses

PET (polyethylene terephthalate, code 1) is likely familiar as the clear, strong plastic used for beverage bottles and food jars. Its strength and clarity make it highly desirable. Its recycled form, rPET, is one of the most widely recycled plastics globally. PET recycling yields rPET flakes and pellets that have numerous applications within the packaging industry and beyond.

Besides being used for new bottles and containers, rPET can be spun into polyester fibers used in clothing and textiles (sometimes blended with virgin polyester) or molded into clear, rigid items like hang tags for garments.

4.2 Spotlight on HDPE (rHDPE): Strength and applications

HDPE (high-density polyethylene, code 2) is generally stiffer and more opaque than PET. Think of milk jugs, detergent bottles, and sturdy pipes. Its robustness makes it suitable for applications demanding durability. Recycled HDPE (rHDPE), derived from HDPE recycling, is commonly used to make non-food bottles (like for cleaning products), pipes, plastic lumber, crates, and bins.

While less frequently used for the flexible poly mailers favored by apparel brands, rHDPE pellets might be incorporated into more rigid shipping containers or certain accessory components requiring strength.

4.3 Spotlight on LDPE and PP (rLDPE/rPP): Key for flexible packaging

LDPE (low-density polyethylene, code 4) is known for its flexibility, making it ideal for films, plastic wraps, grocery bags, and some squeezable bottles. PP (polypropylene, code 5) offers good heat resistance, barrier properties, and relative stiffness, commonly used for yogurt containers, bottle caps, and certain types of films and labels.

These two plastics, particularly LDPE and its blends, are crucial for flexible packaging like the ubiquitous poly mailers used in e-commerce apparel shipping. Recycled versions, rLDPE and rPP, are increasingly incorporated into these mailers and bags, often sourced from post-consumer waste sources like recovered retail bags or industrial film scrap.

However, collecting and effectively recycling thin films can present more challenges than recycling rigid containers like bottles.

4.4 The challenge of mixed plastics and films

A significant recycling barrier arises with packaging constructed from multiple, tightly bonded layers of different plastic types or materials (like plastic fused with aluminum foil). Similarly, very thin, flimsy films can be difficult for sorting machinery to handle effectively.

Standard mechanical recycling processes rely on separating plastics by type; when layers cannot be easily separated, or when films contaminate bales of other plastics, recycling becomes impractical or impossible with current mainstream infrastructure. This limits the circular potential for some complex packaging designs.

4.5 A note on color

When using virgin plastic, manufacturers have complete control over color, easily achieving bright whites or precise brand colors. Recycled plastic, especially material derived from mixed post-consumer sources, presents limitations. The melting process combines plastics of various original colors, often resulting in a final material that is greyish, off-white, beige, or has a generally muted tone.

While color sorting during the recycling process helps separate clear/light from colored streams, achieving specific vibrant hues or a pure white can be difficult or require significantly more processing (and cost) when using high percentages of PCR content. Businesses should anticipate potential color variations when opting for recycled materials.

5. Using recycled plastic in your apparel business packaging

Incorporating recycled materials into your packaging is a tangible way to align your operations with sustainability goals. Here’s how it applies specifically to common apparel packaging items:

5.1 Recycled poly mailers: A popular sustainable shipping solution

Poly mailers made with recycled content are readily available and have become a go-to choice for sustainable e-commerce shipping. These mailers most commonly utilize rLDPE (recycled low-density polyethylene). You’ll typically find options with varying recycled content percentages, often ranging from 50% up to 100% post-consumer recycled material.

From a performance standpoint, high-quality recycled poly mailers generally offer tear and puncture resistance comparable to their virgin counterparts, making them perfectly suitable for shipping clothing and other soft goods. Look for features like dual adhesive strips, which allow customers to easily reuse the mailer for returns, further enhancing the sustainable materials sourcing aspect.

5.2 Tags and labels: Incorporating recycled content

Beyond shipping bags, recycled plastic can be integrated into branding elements. Rigid hang tags, for instance, are frequently made using rPET (recycled polyethylene terephthalate), leveraging its clarity and stiffness, similar to virgin PET tags.

Depending on the desired flexibility or finish, other recycled plastics might also be viable options for certain types of tags or labels. Discussing material options with your supplier can reveal possibilities for incorporating recycled content into these customer-facing components.

5.3 Considerations for zipper bags and other accessories

Items like clear zipper bags used for inner garment packaging, or bags incorporating non-plastic elements like metal zippers, can present more complexity regarding recycled content. While the zipper mechanism itself might not be made from recycled material, it’s worth inquiring with suppliers about the possibility of using recycled PE blends (like rLDPE) for the main bag film. Transparency from the supplier is key to understanding which components incorporate recycled materials.

5.4 What to look for: Understanding recycled content percentages and verification

When sourcing recycled packaging, clarity is essential. Look for explicit statements on the product or specification sheets, such as “Made with 80% Post-Consumer Recycled Content.” Don’t hesitate to ask your suppliers direct questions about the recycled content percentages and whether the source is post-consumer (PCR) or post-industrial (PIR).

For greater assurance and trustworthiness, request documentation or look for independent, third-party certifications. The Global Recycled Standard (GRS) is a well-recognized certification that verifies recycled content claims through rigorous audits of the supply chain, providing credible validation.

5.5 Considering the cost factor

A common question revolves around the cost of recycled versus virgin plastic. Pricing for recycled materials can fluctuate, influenced by factors like the market price of virgin resin, collection and processing costs, and overall demand.

Sometimes recycled options are cost-competitive, while other times, particularly for high-percentage, certified PCR content, they may carry a slight premium. It’s helpful to view the use of recycled materials not solely as a raw material expense but as an investment in sustainability, brand reputation, and meeting the expectations of environmentally conscious consumers.

6. Facing the realities: Challenges and limitations of plastic recycling

While using recycled plastic offers substantial benefits, it’s also important to understand the inherent challenges and limitations within current recycling systems.

6.1 The issue of contamination and sorting accuracy

One of the primary hurdles in plastic recycling is contamination. When non-recyclable items, food residues, liquids, or different types of plastics are mixed into the recycling stream, they can significantly compromise the quality of the final recycled material.

Even small amounts of the wrong substance can weaken the plastic or make it unsuitable for certain applications. Furthermore, while sorting technologies have advanced, they are not always perfect. Errors in separating plastic types or colors can lead to batches of recycled material that don’t meet manufacturers’ specifications.

Both contamination and imperfect sorting act as significant recycling barriers, impacting the efficiency and output quality of the process.

6.2 Potential quality degradation

Plastics are made of long polymer chains. Each time plastic goes through mechanical recycling – being shredded, melted, and reformed – these polymer chains can shorten or break down due to the heat and physical stress involved.

This polymer degradation can potentially lead to a gradual decrease in the material’s properties, such as strength, clarity, or flexibility, impacting its overall quality. Consequently, plastic often cannot be recycled indefinitely into the same product (closed-loop recycling).

Instead, it might be used for less demanding applications in subsequent cycles. This process is known as downcycling, where a material is recycled into a product of lower value or quality (e.g., a clear PET bottle being recycled into opaque carpet fiber, which is harder to recycle further).

6.3 Why isn’t everything made from 100% recycled plastic?

Several factors prevent the universal use of 100% recycled plastic content:

- Availability: There simply isn’t enough high-quality recycled plastic collected and processed to meet the total demand for plastic production globally.

- Quality requirements: Certain products, especially those requiring high strength, specific barrier properties, or medical-grade purity, may technically necessitate the inclusion of virgin plastic to meet performance standards due to potential polymer degradation in recycled streams.

- Contamination: As mentioned, contamination issues can render batches of recycled plastic unsuitable for sensitive applications like food packaging or require blending with virgin material.

- Downcycling effects: The cumulative effects of downcycling mean that not all collected plastic can be perpetually turned back into its original form; eventually, it may only be suitable for lower-grade uses or become unrecyclable.

6.4 The role of emerging technologies

To address some limitations of traditional mechanical recycling, new technologies are under development, often grouped under the umbrella of chemical recycling (also termed advanced recycling or feedstock recycling).

These processes aim to break down plastic waste, including mixed or contaminated streams, into its basic chemical components (monomers or other hydrocarbons). These building blocks can then theoretically be used to create new plastics with properties identical to virgin material.

While holding promise for handling difficult-to-recycle plastics and potentially overcoming downcycling, chemical recycling technologies are generally more energy-intensive and are still less widespread and commercially mature compared to established mechanical recycling methods.

7. Making informed choices: Your role as a business owner

Actively choosing recycled materials is a positive step, but ensuring you’re making the best choices for your brand and the environment requires diligence.

7.1 Asking the right questions to your suppliers

Engaging effectively with your packaging suppliers is crucial. Don’t hesitate to ask detailed questions to understand exactly what you are purchasing. Consider these key inquiries:

- What specific percentage of recycled content is used in this product?

- Is the recycled content post-consumer recycled (PCR) material, post-industrial recycled (PIR) material, or a mix?

- Can you provide documentation or third-party certification (like GRS) to verify the recycled content percentages and origin claims?

- Are there minimum order quantities specifically for the recycled content options?

- What are the color possibilities and limitations associated with the recycled material used? Are bright whites or specific custom colors achievable?

- If possible, can you share information about the general origin or source type of the recycled material (e.g., derived primarily from bottles, films, etc.)?

7.2 Communicating your sustainable choices to customers

Once you’ve chosen packaging with recycled materials, sharing this commitment with your customers can significantly enhance your brand’s trustworthiness. Be transparent and authentic in your communication. Clearly state the use of recycled content on the packaging itself, on a dedicated sustainability page on your website, or within your marketing messages.

Importantly, explain why you made this choice – focusing on the environmental benefits like reducing waste or conserving resources. This narrative connects with evolving consumer behavior, where shoppers increasingly favor brands demonstrating genuine sustainability practices. Avoid vague claims or exaggerations (greenwashing); honesty about your efforts, even incremental ones, builds more credibility.

7.3 Contributing to the circular economy

Opting for recycled content in your packaging extends beyond simply using waste material. You are actively participating in the transition towards a circular economy. Unlike the traditional linear model (take-make-dispose), circular economy principles focus on keeping materials in use for as long as possible, extracting maximum value, and then recovering and regenerating products and materials at the end of their service life.

By choosing recycled plastic, you help close the loop, reduce the demand for virgin resource extraction (addressing resource depletion), and support a system designed for greater environmental and economic resilience. View this choice as a proactive contribution to a more sustainable operational model.

8. Related questions

8.1 Is recycled plastic as durable as virgin plastic for poly mailers?

Generally, yes. For standard apparel shipping applications, high-quality recycled poly mailers, particularly those made primarily from rLDPE, are engineered to offer durability comparable to mailers made from virgin plastic. They provide similar levels of resistance to tears, punctures, and water.

However, the quality and consistency can depend on the source of the recycled material and the specific manufacturing process. Minor variations might exist. Sourcing from reputable suppliers who maintain quality control standards is essential to ensure the recycled mailers meet your performance expectations for protecting garments during transit.

8.2 How can I verify the percentage of recycled content in packaging materials?

Verifying claims about recycled content percentages involves a few approaches. Firstly, look for clear, specific statements on the packaging itself or in the product specifications provided by your supplier – for example, “Made with 80% PCR content.” Don’t hesitate to ask your supplier directly for supporting documentation or data sheets that substantiate these claims.

For the highest level of assurance, seek out products certified by independent third-party organizations. Certifications like the Global Recycled Standard (GRS) or the SCS Recycled Content Standard involve rigorous audits of the supply chain to confirm the type and percentage of recycled material used. GRS verification, for instance, provides strong evidence of trustworthiness regarding recycled content claims.

Yes, color limitations are a common reality when working with recycled plastics, especially those containing significant amounts of post-consumer recycled material. The feedstock often comes from a mix of previously colored items, and melting them together typically results in off-white, grey, beige, or muted tones. Achieving a bright, pure white or highly specific Pantone colors can be difficult or impossible, particularly with 100% recycled content.

If precise color matching or a very bright base is critical for your branding on tags or mailers, you may need to consider options with lower percentages of recycled content, use specifically sorted (and potentially more expensive) recycled streams, or explore printing techniques that can compensate for the base material color.

8.4 What’s the difference between ‘recyclable’ and ‘recycled’ packaging?

These terms are distinct and important to understand. ‘Recyclable’ indicates that a material or product can theoretically be processed through existing recycling infrastructure – although the availability of suitable facilities may vary geographically.

‘Recycled’ means the packaging material actually contains content that has been recovered from plastic waste (either post-consumer or post-industrial) and reprocessed. Therefore, packaging can be described as recyclable, made with recycled content, both, or neither.

8.5 Does using recycled plastic significantly increase my packaging costs?

The cost difference between recycled plastic and virgin plastic packaging is variable and depends heavily on market conditions. Prices for both types of resins fluctuate based on supply, demand, and raw material costs (like oil prices for virgin plastic).

Sometimes, recycled options like rLDPE poly mailers are competitively priced or even slightly cheaper than their virgin equivalents. Other times, particularly for certified, high-percentage post-consumer content, there might be a modest premium.

It’s best practice to get current quotes from suppliers. However, consider the overall value proposition: using recycled materials aligns with sustainability goals, enhances brand image, and meets growing consumer demand for eco-conscious practices, which can offer value beyond the raw material cost.

Read more:

To summarize, recycled plastic represents a valuable shift away from reliance solely on virgin materials, transforming waste into a resource for new products. The environmental benefits are substantial, including significant energy savings during manufacturing, reduced dependence on finite fossil fuel resources, and crucial diversion of plastics from overcrowded landfills and sensitive ecosystems.

Making the switch to recycled content is more than just a material substitution; it’s an active participation in the principles of a circular economy, helping to keep materials in use and lessen environmental strain. Viewing recycled plastic not as a compromise but as a responsible and forward-thinking choice allows businesses to align their operations with ecological consciousness and evolving consumer expectations.

Making informed choices about your packaging materials is a powerful way to contribute.