Perforation Guide for Clothing Tags And Packaging

Understanding perforation can enhance your product presentation and customer experience. This guide explores what perforation entails, its practical applications in the apparel industry – particularly for tags, labels, and packaging like poly mailers – how perforation is achieved, and key design considerations to help your clothing business utilize this feature effectively.

1. Understanding perforation: More than just holes

Perforation is a common finishing technique, but understanding its specifics is key to using it effectively.

1.1 The basic concept: Creating a line of openings for separation

At its core, perforation involves creating a series of small cuts or holes (collectively, openings) made in a material, such as paper, cardstock, or plastic film. These openings form a predetermined line or pattern designed to allow the material to tear cleanly and easily along that path.

The primary purpose is controlled separation. Think of the edge of a sheet of postage stamps – the perforations allow you to detach one stamp without ripping the others.

1.2 Defining features: Holes, slits, and patterns

Perforations typically take the form of:

- Small round holes

- Short linear slits

These individual openings are arranged in a specific pattern. The size of each opening and the spacing between them directly influence how easily the material tears. Closer spacing or larger openings generally lead to an easier tear. While less common for standard tags, very fine openings are termed “micro-perforation,” sometimes used for security features or breathability.

1.3 Perforation vs. scoring: A key distinction for finishing

Understanding the difference between perforation and scoring is crucial when communicating with manufacturers or printers.

- Perforation: Creates a series of small holes or slits that penetrate through the material, forming a separation line intended for tearing. It’s a specialized form of die-cutting focused on separation.

- Scoring: Creates a crease or indentation on the surface of the material, weakening the fibers along a line to facilitate clean folding. Scoring does not break through the material.

Knowing this distinction ensures you specify the correct finishing process – perforation for tear-offs, scoring for folds.

Beyond being a simple manufacturing process, perforation offers tangible benefits for clothing businesses.

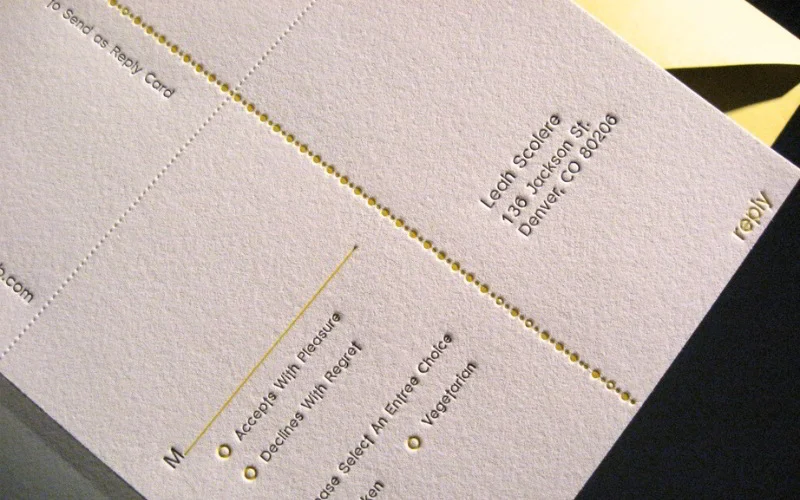

One of the most common uses is on hang tags. Perforations allow for the creation of easily detachable sections. This is frequently used for a price stub, enabling cashiers or customers to remove the price cleanly without damaging the main branded part of the tag.

Similarly, return information or care instructions can be placed on a tear-off portion for customer convenience after purchase. The goal is clean separation without needing tools or leaving a messy tear. This is applicable to both paper and some thicker or more robust labels.

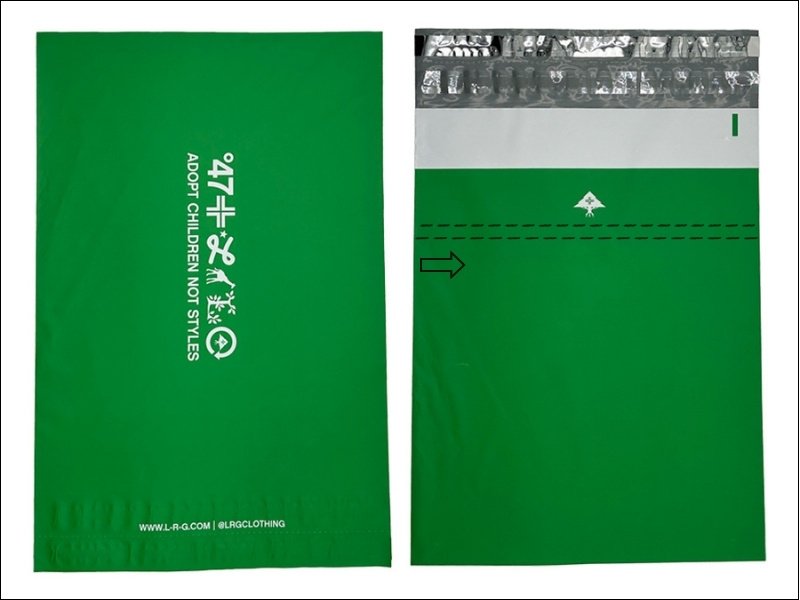

2.2 Convenience factor: Easy-open features on poly mailers

Perforation significantly enhances packaging usability, especially with poly mailers. Incorporating a perforated tear strip provides an easy opening mechanism. Customers can open the mailer quickly and neatly without resorting to scissors or knives, which reduces frustration and minimizes the risk of accidentally damaging the clothing inside. This adds a layer of convenience that customers appreciate.

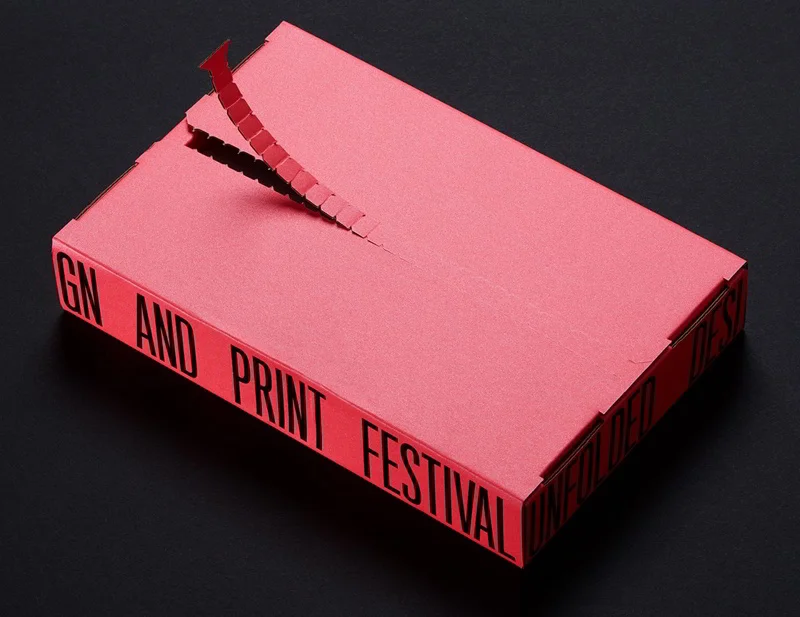

2.3 Elevating the brand: Enhancing the customer unboxing experience

Thoughtful packaging design contributes significantly to the overall customer experience. Features like well-executed perforations for easy opening or neat tear-off sections on tags demonstrate attention to detail. This subtle element enhances the unboxing process, making it smoother and more pleasant, which reflects positively on your brand perception and perceived quality.

3. Seeing perforation in action: Common apparel industry examples

Perforations appear in several common applications within the apparel sector.

This is the most frequent application. Look for a line of small holes or slits on hang tags, creating a deliberate tear point. Common uses include detaching a price stub or separating promotional information from the main tag. The pattern of perforation allows for easy separation while keeping the main tag intact until removal.

3.2 Within product labels

While not as common as on hang tags, perforations might occasionally appear on product labels, such as a long woven label or printed label containing extensive care instructions in multiple languages. A perforated line could allow for separation of sections, though this application is relatively rare for standard clothing items.

3.3 Integrated into packaging materials

Perforation is a key packaging feature, primarily as an opening aid. Beyond the tear strip on external poly mailers, perforations might be used on inner protective bags (like those used for folded shirts) or on certain types of seals or stickers within the package to facilitate easier access to the product. To include this functional element, the packaging material undergoes specific processing.

4. How are perforations typically made?

Creating perforations is typically part of the manufacturing and finishing process.

4.1 Common methods: Die-cutting and punching tools

Perforations are usually made mechanically during the finishing stage after printing. Two common manufacturing techniques involve:

- Die cutting: A custom-made metal die (a tool with sharp edges or blades) with specialized teeth or blades is used to punch or pierce the material in the desired pattern.

- Rotary punching tools: Wheels or cylinders with projecting pins or blades rotate against the material to create the perforation line as the material passes through the machine.

The specific process depends on the material, volume, and desired perforation pattern.

4.2 Material matters: Adapting techniques for paper vs. plastic film

The choice of printing and finishing techniques, including the perforation tool and pressure, must be adapted to the specific material properties. Creating clean perforations in thick cardstock requires different settings than perforating thin poly film. The pattern (hole/slit size and spacing) needs to ensure a reliable tear on materials like paper without prematurely weakening flexible materials like plastic film.

5. Key considerations when designing with perforation

Successfully incorporating perforation requires attention to material and design details.

5.1 Choosing the right material: Compatibility is crucial

Material compatibility is paramount. Not all materials perforate cleanly or reliably.

- Standard paper and cardstock weights used for hang tags generally perforate well.

- Common poly films used for mailers are designed to accommodate perforation.

However, very thick or highly brittle cardstock might crack or tear unevenly. Extremely thin or stretchy films might require specific perforation designs to avoid accidental tearing before intended use. Consulting with your supplier about material suitability based on its thickness and properties is essential.

5.2 Design integration: Placement, tear strength, and aesthetics

Consider these practical design aspects:

- Placement: Position the perforation line logically for its functional purpose. Ensure the line doesn’t cut through vital information or compromise the structural integrity of the tag or package before tearing.

- Strength: The perforation pattern must strike a balance. The connection needs to be strong enough to hold during handling and shipping but weak enough to tear easily when intended.

- Aesthetics: The perforation line should look neat and deliberate. Poorly executed perforation can appear messy and detract from the perceived quality. Aim for a clean tear quality. Proper design integration considers both physical performance and visual appeal.

5.3 Types of perforation: Standard lines vs. micro-perforations

Be aware of the main types:

- Standard perforation: The most common type for tags and mailers, featuring visible holes or slits designed for easy manual tearing. The pattern is clearly intended for separation.

- Micro-perforations: Consist of extremely small, closely spaced holes. While sometimes used for breathability in films or as security features, these are less typical for the simple tear-off functions needed in most apparel tag and packaging applications.

Understanding which type is suitable (usually standard) helps in specifying requirements.

6. Related questions

Here are answers to some common questions about perforation in apparel applications.

No, not every material perforates equally well. Effectiveness depends heavily on the material’s properties, including thickness, flexibility, and composition. Standard paper, cardstock, and common poly film types used for tags and mailers are generally suitable when the correct perforation technique is applied.

However, very rigid boards, brittle plastics, or certain laminated materials might pose challenges, potentially leading to cracking or ragged tears. Consulting with your supplier is the best way to ensure material compatibility.

Adding perforation represents an additional finishing step, which typically involves specific tooling (like a custom die-cutting). Therefore, there is usually a small incremental cost compared to items that are only printed and cut.

However, especially on larger production runs, this cost per piece is often minimal and can be easily justified by the functional benefits (like easy tear-offs) or enhanced customer experience it provides for tags or packaging. The exact cost varies based on the complexity of the perforation and the supplier’s processes.

6.3 Is a perforation the same thing as a tear strip on a poly mailer?

Often, a tear strip on a poly mailer relies on perforation to function. The tear strip is the user-facing feature designed as an opening aid. Perforation is typically the underlying mechanism – the line of weakness created by small holes or cuts – that allows the tear strip to work effectively and guide the tear cleanly. So, while related, perforation is the method, and the tear strip is the application or feature enabled by that method.

Read more:

Perforation is fundamentally a line of controlled openings designed for easy separation. In the apparel industry, its value shines in creating functional tear-off sections on hang tags and labels, and convenient easy-open features on packaging like poly mailers.

Successful implementation hinges on choosing the right material and thoughtful design, considering factors like placement, tear strength, and aesthetics. When used appropriately, perforation is a simple yet effective tool to enhance product usability and elevate the customer experience. Consider how this finishing technique could improve your own product presentation or packaging convenience.

For personalized advice on designing tags, labels, or packaging with features like perforation tailored to your clothing business, visit Packlove to explore options and consult with our experienced team.