Printed Apparel Labels: Materials, Print Types and Uses

Often small and seemingly simple, the printed apparel label plays a crucial role far beyond just stating a size. It’s a vital touchpoint for brand identity, a carrier of essential care and content information, and a key element in a garment’s overall professional presentation.

Choosing the right combination of material and printing method is critical to ensure the label is durable, legible, and aligns perfectly with your brand’s image and the garment’s function. This guide delves into the diverse world of printed apparel labels, exploring the common materials used, the various printing techniques available, and their specific applications, helping you make informed decisions for your clothing line.

1. Understanding the Basics: What Exactly is a Printed Apparel Label?

1.1 The Fundamental Concept: Ink Applied to Fabric Substrates

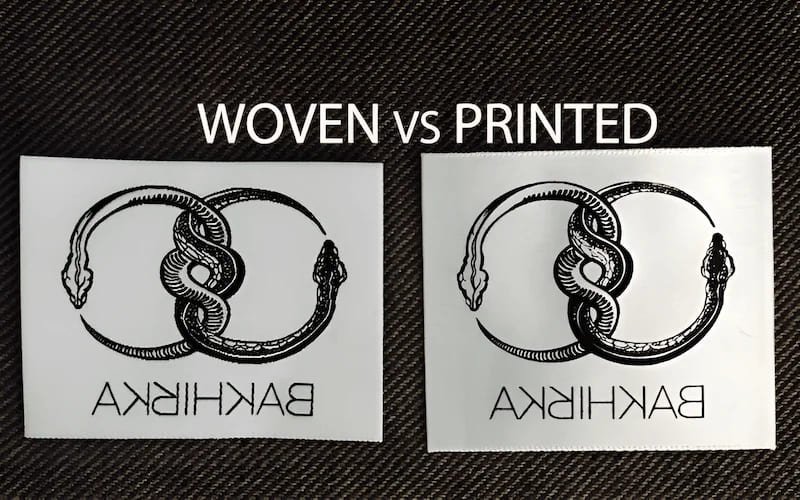

A printed apparel label is fundamentally created by applying specialized inks directly onto the surface of a chosen fabric material (such as satin, cotton, or polyester). Unlike woven labels, where the design forms part of the fabric’s structure through interwoven threads, a printed label features the design as a layer sitting atop the base material.

Printed labels are thus distinct pieces of garment trim used for product identification, with the design sitting atop the base material. The specialized ink bonds with the fabric material to ensure longevity.

1.2 Core Identifying Features & Purpose

Printed labels fulfill several crucial roles within apparel:

- Brand Labels: They prominently display logos, brand names, and other brand identity elements.

- Care Labels: These provide essential information conveyance, including washing instructions, fiber content details required by regulations, and the country of origin.

- Size Indicators: Often integrated into brand or care labels, or as standalone tabs, indicating the garment size.

Key visual characteristics include a relatively smooth surface compared to the texture of woven labels, allowing for the potential reproduction of fine details and complex graphics depending on the printing technique used. These custom label types are vital for branding and consumer information.

2. Choosing Your Canvas: Common Materials for Printed Clothing Labels

2.1 Polyester Satin: The Smooth Standard

Polyester satin stands out as a widely used base material composition for printed labels, recognized for its smooth, often slightly shiny finish. This characteristic tends to lend a higher-quality feel to branding material.

- Pros: Offers an excellent surface for clear printing, possesses a pleasant tactile quality against the skin.

- Cons: Can be prone to snagging under certain conditions; the edges may fray if not properly finished (e.g., heat cut or folded). Common applications include main brand labels positioned inside the neck or side seam of garments.

2.2 Cotton Labels: Natural Feel, Specific Applications

Cotton provides a distinct natural texture for labels, offering a softer, matte appearance and feel.

- Pros: Presents a natural aesthetic appealing to certain brand identities, generally comfortable when in contact with skin. Using organic cotton enhances sustainability claims.

- Cons: Cotton’s absorbency can sometimes affect the absolute sharpness of the ink print; may exhibit lower durability compared to synthetic options during harsh washing cycles.

This textile component is particularly suitable for organic clothing lines, childrenswear, or brands emphasizing natural materials and a softer touch.

2.3 Polyester Taffeta: Crisp & Economical

Polyester taffeta represents a crisper, frequently less soft polyester alternative, usually offering a more economical choice for labels.

- Pros: A cost-effective option, holds its shape well, providing a stable base for printing.

- Cons: Can feel somewhat stiff or scratchy against the skin, especially lower-quality versions; generally lacks a premium tactile sensation.

The crisp feel makes taffeta best suited for basic information labels, like straightforward care instructions or applications where minimizing cost is the primary objective.

2.4 Tyvek®: Unrivaled Durability for Care Information

Tyvek® is the brand name for a unique flashspun high-density polyethylene material. Appearance-wise, Tyvek® resembles paper but possesses exceptional tear-resistant and water-resistant qualities.

- Pros: Highly durable, excellent surface for printing very fine text like detailed care instructions, withstands harsh washing conditions extremely well.

- Cons: Has a distinct paper-like texture and feel, rendering Tyvek material unsuitable for soft brand labels intended for skin contact.

Its primary application is for legally required care labels and law labels (labels containing manufacturing information required by law), often hidden inside seams due to the unique feel. Wash care labels made from Tyvek ensure information remains legible throughout the garment’s life.

2.5 Eco-Conscious Options: Exploring Sustainable Choices

The demand for sustainable label choices is growing, leading to increased availability of eco-friendly materials. Options include recycled polyester (rPET), often made from post-consumer plastic bottles, and certified organic cotton, grown without synthetic pesticides or fertilizers.

Benefit: Opting for these sustainable materials helps reduce environmental impact by conserving resources and minimizing waste.

Availability, specific characteristics, and price points for these materials might vary between suppliers, so inquiries are recommended for brands prioritizing eco-friendly solutions.

3. How They’re Made: Exploring Printing Techniques for Fabric Labels

3.1 Screen Printing: Time-Tested for Bold Designs & Volume

Screen printing involves pushing printing ink through a mesh screen stencil onto the fabric substrate. Each color typically requires a separate screen.

- Advantages: Creates a durable, often slightly raised ink layer; excellent for solid, bold graphics and simple designs; becomes cost-effective for high volume orders with a limited number of colors.

- Limitations: Less suitable for reproducing photographic details or smooth color gradients; involves setup costs for each screen (color), making small runs with multiple colors expensive.

Ideal scenarios include simple logos, block text care instructions, and large quantity orders where design complexity is low. These printing techniques are a staple in label production.

3.2 Flexographic (Flexo) Printing: Efficient for High Runs & Solid Colors

Flexographic printing utilizes flexible photopolymer relief plates mounted on rotating cylinders. Fast-drying inks are transferred to the label material, often processed in a continuous roll-to-roll format.

- Advantages: Very high speed, making flexo extremely efficient for high volume production, particularly for roll labels; provides good ink coverage and opacity; excels at accurate spot color matching using systems like Pantone Colors.

- Limitations: Plate creation involves costs that can be prohibitive for short runs; less adept at rendering fine photographic detail compared to digital methods. The label printing process using flexo is ideal for massive quantities of care labels or brand labels where precise color matching is critical.

3.3 Digital Printing: The Modern Solution for Detail, Gradients & Small Runs

Digital printing functions similarly to a desktop inkjet or laser printer, applying inks directly onto the label material based on a digital file (like a PDF or JPG).

- Advantages: Exceptional for reproducing fine details, photographic quality images, and smooth color gradients; offers unlimited colors within a single design; typically involves no setup costs per color, making small runs economical; enables variable data printing (unique codes, sequential numbers, or different sizes on each label within a run). A great option for small business supplies.

- Limitations: The ink layer might be thinner and potentially less durable under extreme wash conditions compared to screen printing (though technology varies); production speed for massive volumes may lag behind flexo. Ideal scenarios include complex logos, labels featuring photographs, brands needing low MOQ (Minimum Order Quantity), and applications requiring unique information on each label. Detailed image reproduction is a key strength.

3.4 Understanding Ink & Durability Additives

The quality of printed labels hinges significantly on the printing ink used. Specialized textile inks are formulated to bond effectively with fabric fibers and withstand repeated washing and drying cycles. For enhanced wash resistance and improved colorfastness properties, sometimes an ink catalyst (a substance that speeds up the ink curing and bonding process) is mixed with the ink, or specific curing methods (like heat or UV light) are employed after printing. These steps are crucial for label durability characteristics, especially for care labels subjected to frequent laundering.

4. Printed vs. Woven Labels: A Clear Comparison for Your Brand

4.1 Aesthetics: Look, Feel, and Perceived Quality

Comparing printed and woven labels involves considering their visual and tactile differences:

- Woven: The design is integrated into the fabric structure itself, resulting in a textured feel. Often associated with a more premium or luxurious perceived quality due to the intricate construction.

- Printed: Features a smoother surface appearance (though the base material influences this); the design rests on top. Can achieve sharp, modern looks but might feel less substantial or “rich” compared to woven counterparts.

4.2 Design Fidelity: Detail, Color Gradients, and Text Legibility

Each label type has strengths and weaknesses regarding design reproduction:

- Woven: Can struggle with extremely fine details, smooth color gradients, and photographic images due to the nature of weaving threads. Typically has color limits (e.g., a maximum of 8 or 12 distinct thread colors per design).

- Printed (especially Digital): Excels at rendering fine details, complex gradients, and photographic quality labels. Offers virtually unlimited colors. Superior for ensuring small text readability, critical for care instructions.

4.3 Durability Deep Dive: Wash Resistance and Longevity Expectations

Durability varies between the two types and within printed methods:

- Woven: Generally exhibits very high label durability as the design is integral to the fabric, and threads are typically yarn-dyed (color runs through the thread). Excellent wash fastness.

- Printed: Longevity depends heavily on the print method, ink quality, and base material. High-quality screen printing often offers excellent durability. Digital prints, while resilient with modern inks, can be more susceptible to fading or cracking over extensive, harsh washing compared to woven labels or robust screen prints. Wear and tear affect surface prints more directly. Tyvek® offers exceptional wash resistance level for printed information.

4.4 Cost Factors: Setup, Per-Piece Pricing, and Volume Impact

Cost considerations differ significantly:

- Woven: Involves higher initial setup costs related to programming the loom for a specific design. The per-piece price tends to decrease substantially at very high volumes. Often involves higher setup costs (loom programming). Per-piece cost can decrease significantly at high volumes.

- Printed: Screen and flexo printing have setup costs per color or plate, respectively. Digital printing often has minimal or no setup costs, making short runs more affordable. While the initial per-piece cost for printed labels might be lower, the price may not decrease as dramatically as woven labels at extremely large quantities. Overall, printed labels generally offer a lower cost entry point, especially for designs with many colors or for smaller order volumes. This makes printed labels a frequent cost factor advantage.

4.5 Turnaround Time: Production Speed Considerations

Production timelines typically differ:

- Woven: Generally requires a longer manufacturing turnaround time due to the loom setup and the physical weaving process.

- Printed: Often provides a faster turnaround time. Digital printing is particularly quick for small to medium runs with minimal setup. Flexo printing is extremely fast for large volumes once plates are made. Faster order fulfillment time is a common benefit of printed options.

4.6 Decision Helper: Quick Guide for Choosing

This table provides a quick reference based on key factors to aid in label selection guide efforts:

| Feature | Printed Labels | Woven Labels |

|---|---|---|

| Detail/Gradients | Excellent (esp. Digital) | Fair to Good (Limited) |

| Durability | Good to Very Good (Varies by Type) | Excellent |

| Perceived Quality/Feel | Good (Varies by Material) | Excellent (Often Premium Texture) |

| Small Text Legibility | Excellent | Fair to Good |

| Cost (Low Volume) | Lower (esp. Digital) | Higher |

| Cost (High Volume) | Moderate to Low | Lower |

| Speed (Turnaround) | Faster | Slower |

| Use Case Suitability | Care labels, complex graphics, photos, variable data, faster needs | Premium branding, simpler logos, high durability needs |

5. Practical Factors for Your Apparel Business

5.1 Aligning Label Choice with Garment Type & Brand Position

Consider the specific garment and your brand’s market position when selecting labels. A high-end cashmere sweater from a luxury apparel brand might warrant a premium woven main label, while a basic cotton t-shirt from a budget-friendly line could use a well-executed printed label.

Childrenswear often benefits from softer printed labels (like cotton or soft satin). The label contributes to the overall brand perception and should align with the garment type and intended customer experience. Your brand identity should guide this choice.

5.2 Assessing Real-World Durability Needs for Your Products

Think critically about how customers will use and care for the garments. Workwear, sportswear, or children’s clothing typically undergo frequent and potentially harsh washing and drying cycles, demanding higher durability requirements for labels.

Delicate blouses or outerwear washed infrequently have less stringent needs. Aim to match the expected label longevity to the anticipated lifespan and use intensity of the product itself. Customer usage patterns are key.

5.3 Budget Allocation: Balancing Quality and Cost-Effectiveness

For any clothing manufacturer, especially a small business owner or startup, balancing the desire for high-quality presentation with budget constraints is crucial. A cost-effectiveness analysis is necessary. Different printing methods (digital vs. screen/flexo) and materials carry different label cost implications.

Consider investing more in the primary brand label, which significantly impacts brand perception, while potentially opting for a more economical solution (like printed taffeta or Tyvek®) for essential care and compliance information often hidden inside the garment. Effective budgeting helps prioritize spending.

5.4 Attachment Considerations: Sew-in vs. Iron-on Printed Labels

Printed labels typically offer two main label application methods:

- Sew-in Label: The traditional method where the label is stitched directly onto the garment. Provides a secure and potentially more durable long-term attachment.

- Iron-on Label: Features an adhesive backing activated by heat (using an iron or heat press). Offers faster application without needing sewing capabilities. However, the durability depends heavily on the quality of the adhesive and the correct application process (temperature, pressure, time).

Note that not all printed label materials are suitable for an iron-on adhesive backing; softer or heat-sensitive materials might require sewing.

6. Expert Insights: Achieving Quality Custom Printed Labels

6.1 Artwork Preparation Best Practices for Clear Prints

Submitting print-ready artwork is essential for achieving high-quality results. Follow these guidelines for artwork preparation:

- Use vector art formats (like AI, EPS, vector PDF) for logos, text, and line art whenever possible. Vector graphics scale infinitely without losing sharpness.

- Ensure any raster images (photos, complex graphics) have a high resolution, typically a minimum of 300 dots per inch (dpi) at the final print size.

- Outline all fonts (convert text to shapes) or provide the font files used in your label design to avoid substitution issues.

- Specify Pantone color codes if precise color matching is required, particularly for screen printing or flexographic printing.

- Clearly define the exact label dimensions, including any required bleed (area extending beyond the cut line) or safe zones (area within which critical elements must stay) as specified by your label supplier. Using appropriate design software facilitates these steps.

6.2 Understanding Fold Options and Their Best Uses

The way a label is finished affects its application and appearance. Common fold options include:

- End Fold: Both short ends of the label are folded under. Typically sewn down along the short edges, lying flat against the garment. Often used for brand labels on hems or sleeves.

- Center Fold: The label is folded in half lengthwise. Usually sewn into a seam (like a neckline or side seam), with the loop protruding. Ideal for brand or care information inside seams.

- Mitre Fold: The short ends are folded up at a 45-degree angle, creating points. Sewn along the top edge, allowing the label to hang down. Often used as a hanger loop or decorative element at the back neck.

- No Fold / Straight Cut: The label is cut on all four sides with no folds. Requires sewing around all edges or just along the top edge. Suitable for patches or labels applied flat.

Choosing the right fold depends on the desired placement and look. These customization options enhance label application flexibility.

6.3 The Importance of Requesting Samples Before Full Production

Strongly consider requesting physical samples of your exact custom label before committing to a full production run. This means obtaining a sample using the specified material, printing method, colors, and finishing. Samples allow for a thorough quality check of:

- Print clarity and detail reproduction.

- Color accuracy against your specifications.

- Material feel and quality.

- Overall appearance and finishing (cuts, folds).

- Preliminary wash testing (if possible).

This approval process significantly reduces the risk of receiving a large batch of labels that don’t meet expectations, saving potential time, money, and frustration. Risk mitigation through sampling is a prudent step.

7. Related Questions

7.1 Can printed labels be made from sustainable or recycled materials?

Yes, absolutely. Sustainable label choices are increasingly common. Options like recycled polyester (often GRS certified – Global Recycled Standard) made from post-consumer plastic, and organic cotton (potentially GOTS certified – Global Organic Textile Standard) grown without synthetic pesticides, are available for printed labels.

Utilizing these recycled materials or eco-friendly fibers helps reduce environmental impact by conserving virgin resources and diverting waste from landfills. Discuss specific certifications and material properties with suppliers if sustainability is a priority for your brand.

7.2 What are the typical minimum order quantities (MOQs) for custom printed labels?

Minimum Order Quantity (MOQ) requirements vary significantly depending on the label supplier and the chosen printing technique. Digital printing excels in offering low MOQs, sometimes starting as low as 50 or 100 pieces, making custom label solutions highly accessible for startups and small business needs. Conversely, traditional methods like screen printing and flexographic printing usually involve higher MOQs, often ranging from 500 to 1,000 pieces or more, due to the setup time and costs associated with screens or plates. Always confirm the specific MOQ with potential suppliers for the desired label type.

7.3 How do I ensure my care instructions are compliant and legible on a printed label?

Printed labels, particularly those using digital printing or fine screen printing, are well-suited for displaying detailed care instructions due to their ability to render small text clearly. For compliance and legibility:

- Use standard, internationally recognized care symbols wherever possible for universal understanding.

- Research and adhere to the specific textile regulations for your target markets. For example, FTC guidelines in the United States mandate disclosure of fiber content, country of origin, and clear washing instructions.

- Choose simple, highly readable fonts (sans-serif fonts often work well).

- Ensure the text size is adequate for easy reading, even after some wash cycles. Consulting supplier guidelines or requesting samples can help verify legibility.

7.4 Are digitally printed labels durable enough for repeated washing?

This is a frequent question. Modern, high-quality digital printing technology, when paired with specialized textile inks and appropriate base materials (like polyester satin or certain types of nylon), generally offers good wash fastness and digital printing durability suitable for most consumer apparel under typical use conditions.

While extremely harsh industrial laundering or very frequent, abrasive washing might cause fading or wear faster than deeply embedded woven designs or thick screen prints, for the majority of clothing applications, digitally printed labels perform well through repeated washing. The quality of the ink, material, and printing process are key factors influencing label longevity.

Read more:

Printed labels serve as essential components for apparel, carrying vital brand identity and product information directly on the garment. Understanding the nuances of different base materials (like satin, cotton, or Tyvek®) and various printing techniques (screen, flexo, digital) empowers businesses to make informed choices. Comparing printed options against woven labels across factors like aesthetics, detail, durability, cost, and speed clarifies the best fit for specific needs.

Considering practical factors such as garment type, brand positioning, durability requirements, budget, and attachment methods ensures the final label selection aligns with business goals. By leveraging insights on artwork preparation, fold options, and the crucial step of sampling, brands can achieve high-quality results.

Making a thoughtful label selection contributes significantly to overall product quality, compliance, and positive brand perception. For tailored recommendations for your unique apparel line, exploring options with experienced suppliers can provide valuable guidance in navigating these choices for effective apparel branding.