What Are Wales in Knit Fabric? Simple Guide

Curious about what is wales in knit fabric? This guide demystifies wales as the vertical columns of stitches forming the backbone of any knit material. You’ll understand how these crucial lines are created from interlocked loops and why they are fundamental to a fabric’s structure, stretch, and grain.

Packlove helps people and businesses with great packaging and branding items. We believe that knowing about materials, like fabrics, helps make better products. Packlove’s guides on fabric terms like ‘wales’ support better branding decisions for clothing lines.

1. What exactly are wales in knit fabric? The simple definition

1.1 Defining “wales”: The vertical lines you see

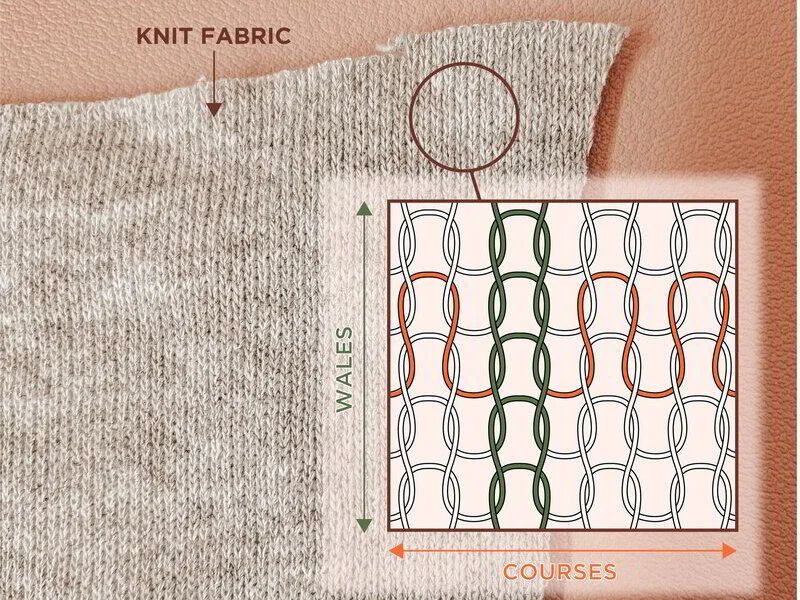

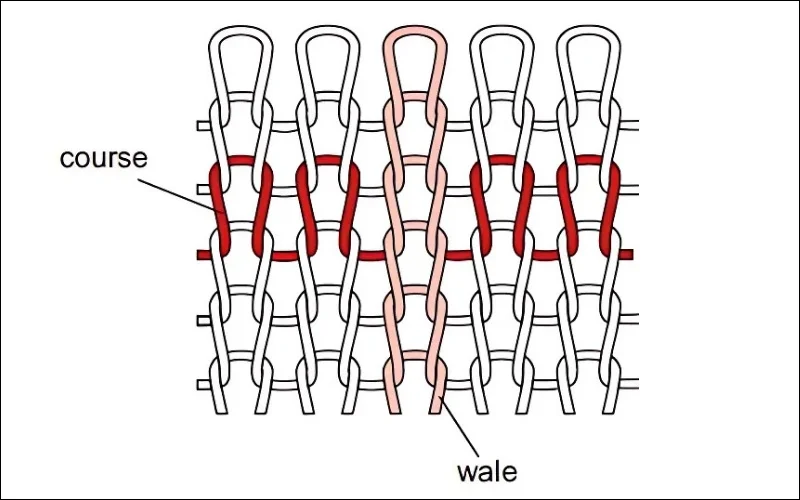

In knit fabric, wales are the lines of stitches that run up and down. Think of them as tiny vertical columns. Each wale is made of many loops stacked one on top of another. These are a very important part of the fabric’s structure.

Understanding wales is key because they represent the basic columns of stitches in knitting. You can see these vertical lines in knitted fabric quite easily if you look closely. This vertical arrangement is fundamental to how knit fabric is made.

1.2 Think of it like this: Easy ways to picture wales

It can be easier to understand wales with a couple of pictures in your mind.

- Imagine many tiny ladders standing side-by-side. Each long side of a ladder is like one wale.

- Or think of corduroy fabric. It has soft ribs that go up and down. Wales in knit fabric are like those ribs. But, wales are made from tiny knit stitch lines of yarn loops instead of cut threads.

Both examples show continuous vertical lines, which is what wales look like.

2. How are wales formed in knitting?

2.1 The magic of loops: The building blocks

All knit fabric starts with yarn. This yarn is made into many loops. Each knit stitch creates one loop. These loops then connect with other loops. This linking of loops creates the fabric. The loop is the most basic part of any knit material. The yarn path is what forms this essential loop.

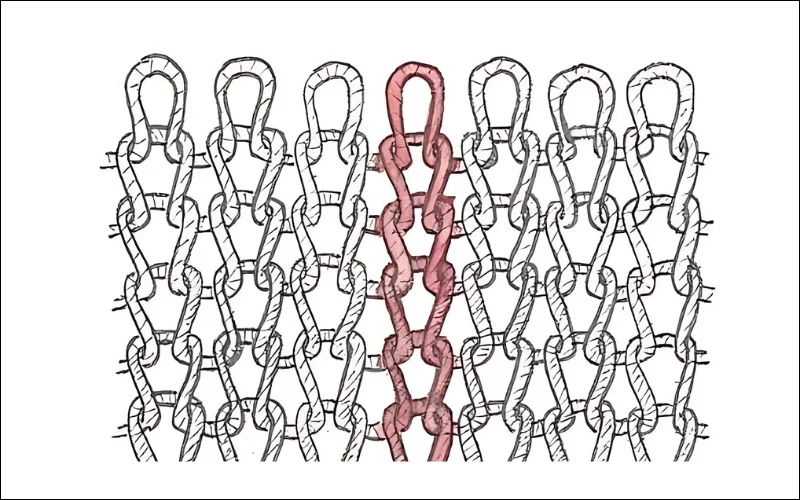

2.2 Stacking the loops: Creating a wale

Making a wale is like building a tall tower with loops. A new loop is pulled through an existing loop that is directly below it. This action repeats. Loops connect one above the other, forming a chain.

This continuous vertical chain of interlocked loops makes one wale. Many of these columns, or wales, sit next to each other. Together, they make up the width of the knit fabric. Knitters create wales on needles by repeating this looping process. A wale is formed by a series of stitches stacked vertically.

When choosing the right label, understanding how these wales give fabric its main structure helps us at Packlove advise on placement.

3. How to spot wales: Looking closely at your knit items

3.1 What to look for: Identifying the vertical columns

It’s easy to see what wales look like in a knit fabric. Take a knit garment you own, like a t-shirt or a sweater. Look closely for lines of stitches that run up and down.

In many basic knits, such as the jersey fabric used for t-shirts, the front of each stitch in a wale looks like a small “V”. These “V” shapes are stacked one on top of another. This stack forms the column, or wale.

Here’s a tip: Gently stretch the fabric sideways, across the wales. This often makes the “V” shapes and the columns (wales) easier to see. If you need to, you can learn how to count wales in knit fabric for certain projects.

When customers send us garments for custom patches, we at Packlove often look at the wales. This helps us understand the fabric’s main structure and decide the best application method for the patch.

3.2 Examples in everyday knits

You can find wales in many common knit items:

- T-shirts (usually jersey knit): these have a smooth surface. You’ll see the “V” shapes on one side.

- Sweaters (can be various knits, including rib knit): rib knits show very clear, raised wales. If you’re wondering what wales are in a knitted sweater, they are these prominent vertical lines.

- Socks: these often have ribbing where wales are very distinct.

- Knit hats/beanies: wales are visible, forming the vertical lines that give the hat its shape.

The appearance of wales can change:

- In jersey knit, wales create a surface that is quite flat and smooth. The “V” shapes are on the face of the fabric.

- In rib knit, wales are very easy to see. They create a textured surface with raised vertical lines. This is because some wales are on the front and some are on the back of the fabric.

Even with different patterns, the basic vertical columns (wales) are always a part of knit structure.

3.3 Counting wales: What is “wales per inch” (WPI)?

You might hear the term “wales per inch” (WPI). The wales per inch knitting definition is simple. WPI tells you how many wales (vertical columns) fit into one inch when you measure across the fabric’s width.

WPI relates to how dense the fabric is:

- A higher WPI (more wales in an inch) means the stitches are smaller. The fabric is finer and denser.

- A lower WPI (fewer wales in an inch) means the stitches are larger. The fabric is coarser and more open.

This is related to what knitters call gauge, which tells them how big their stitches are.

4. Why do wales matter?

4.1 Wales and fabric stretch

Wales run lengthwise, meaning along the length of the fabric. One of the key fabric properties of knits is their stretch. Knit fabrics generally stretch more across their width (from side to side, perpendicular to the wales). They stretch less along their length (up and down, parallel to the wales). The wale contributes to fabric’s vertical stability (less stretch direction).

Why is this? The loop structure allows loops to widen more easily than they can get longer. Knowing this helps you find out how wales affect fabric behavior. It helps predict how a knit garment will fit, drape, and move when worn. For example, a t-shirt stretches more around your body than it does in length.

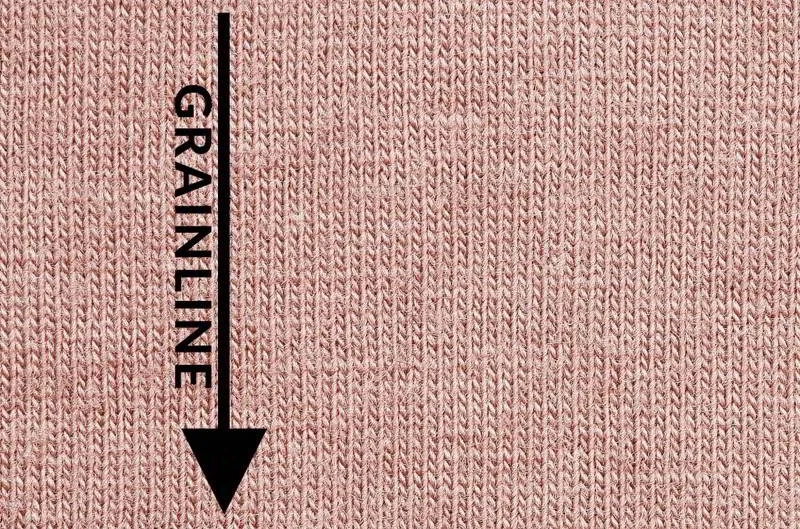

4.2 Wales and fabric “grain”

The direction (vertical) of the wales shows the “lengthwise grain” or “straight grain” in knit fabrics. This is a very important garment detail for cutting fabric when making clothes or other items.

For clothes to fit well and hang nicely, pattern pieces should usually be aligned so the wales run vertically up and down the body. If you cut fabric off-grain (not along the wales), clothes can twist. They might hang unevenly or lose their shape after washing or wearing. Always align pattern pieces with the wales (fabric grain) for best results.

We’ve seen at Packlove that even for items like branded fabric bags or simple apparel, ensuring pieces are cut on-grain (along the wales) makes a big difference. It affects the final product quality and how a logo or design looks.

4.3 Impact on how fabric looks and feels

The size of the wales, how close together they are, and their arrangement all affect how the fabric looks and feels. This includes the texture, pattern, and “handfeel” (how it feels to touch). The overall fabric construction depends heavily on wales.

For example:

- Rib knits: have prominent, raised wales. This creates a textured, elastic fabric.

- Jersey knits: have finer, less obvious wales. This results in a smoother, flatter surface.

- Cable knits: in these, wales are twisted and crossed over each other. This creates decorative, raised patterns.

Different knitting techniques change how wales (and courses, which we’ll talk about next) are arranged. This produces a huge variety of fabric designs, textures, and thicknesses.

5. Wales vs. courses: Clearing up a common confusion

It’s common to hear about “wales” and “courses” together. Knit fabric has wales and courses. Let’s make sure we understand both.

5.1 Introducing “courses”: The horizontal lines

Courses are the horizontal rows of loops in knit fabric. They run side-to-side across the fabric.

Here’s a simple way to remember:

- If wales are the “up and down” lines (like columns)…

- Then courses are the “side to side” lines (like rows).

Just like wales, courses are also made of interlocked loops of yarn.

5.2 The key difference: Vertical vs. horizontal

The difference between wales and courses in knitting is their direction:

- Wales: run VERTICALLY (up and down). They are COLUMNS of loops.

- Courses: run HORIZONTALLY (side to side). They are ROWS of loops.

Here’s a little memory aid: wales go way up (like walls). Courses go across.

Understanding both wales and courses helps when talking about fabric designs. For example, a striped knit shirt might have stripes formed by different colored courses. This is a note from us at Packlove!

6. Packlove’s quick tips: Wales and your branded items

6.1 Choosing labels for knitwear

Now that you know wales affect how knit fabric stretches, let’s talk labels. For stretchy knitwear, labels should also be flexible. This helps them move with the fabric. Stiff labels can cause puckering or damage the knit. At Packlove, we leverage this understanding of ‘wales’ to help you select suitable labels that won’t pucker or damage delicate knitwear.

Soft woven labels (labels made by weaving threads together, like on clothing necklines) or flexible heat transfer labels (labels applied to fabric using heat and pressure, often tagless) from Packlove are often great choices for knits. They don’t restrict movement.

Knowing the direction of wales (the grain) also helps. You can place labels so they hang straight and look professional. Understanding ‘wales’ and knit stretch helps choose the right size and type of Packlove tags for knitted items, especially when choosing labels for stretch fabrics.

6.2 Why understanding fabric helps your brand

Understanding fabric basics, like “wales,” helps you make smarter choices about materials for your products. Smarter choices often lead to better quality products.

High-quality products and attention to detail show customers you care. For example, choosing the right label for how a knit fabric behaves enhances your brand image and trustworthiness. Packlove advises on labeling knits by explaining wales.

At Packlove, we love sharing knowledge like this. We want to help your brand shine with quality materials and thoughtful details.

7. Frequently asked questions (FAQs)

7.1 What are wales in simple terms?

Wales are the lines of stitches that go up and down in any knit fabric. Think of them like tiny vertical columns made of yarn loops. This is how to define wales in knitting simply.

7.2 How do I tell wales from courses?

Easy! Wales run vertically (up and down the fabric). Courses run horizontally (side to side across the fabric). This is the main difference between wales and courses in knitting.

7.3 Do all knit fabrics have wales?

Yes, all fabrics made by knitting have wales. Wales (and courses) are the basic way knit fabric structure is created from loops. The fabric structure includes wales.

7.4 Why is it called “wales”?

“Wale” is an old word used in making textiles. It means a raised line or rib in a fabric. It became the standard textile terminology for these vertical columns in knit fabrics.

7.5 Can wales be uneven or slanted?

Yes, sometimes if a knit fabric isn’t made perfectly or gets stretched unevenly, the wales might not be straight. This is called skew (wales not perfectly vertical). Skewed fabric can make clothes twist or hang oddly.

Read more:

So, there you have it! Wales are columns of loops in knit fabric. Fabrics are fascinating! We hope this simple guide helps you look at knits in a new way. Learning textile basics can be fun and useful. Keep an eye on the Packlove blog for more easy guides on materials and branding tips!