How to Make a Rubber Patch: A Step-by-Step Guide

Creating custom rubber patches is easier than you think! Whether you’re a small business needing branded apparel or an individual wanting personalized accessories, this guide simplifies the process. This guide empowers you to navigate the design and manufacturing process, ensuring your vision translates into reality, high-quality, impactful rubber patches that perfectly meet your needs. Let’s read!

1. Understanding Rubber Patches and Their Applications

1.1 What are Rubber Patches?

Rubber patches stand out as a durable and flexible option in the realm of garment embellishments, often crafted from soft PVC rubber or silicone. When compared to other types of patches, rubber variants offer superior longevity and adaptability.

PVC, or Polyvinyl Chloride, patches are a more economical choice, while silicone patches excel in flexibility and resistance to weather conditions, making them particularly well-suited for items intended for outdoor use. Both PVC and silicone patches are favored for adding a distinctive and lasting touch to a wide array of products. For businesses focused on branding and personalization, the resilience of these patches is a significant advantage across various sectors.

1.2 Common Uses of Rubber Patches Applications across industries

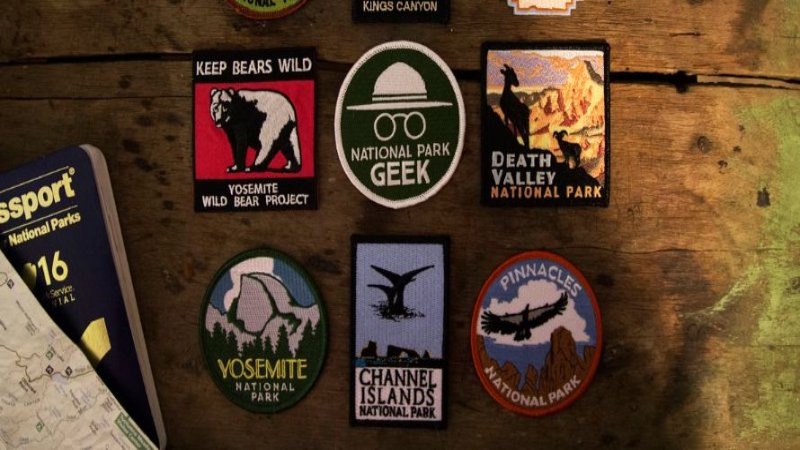

The versatility of rubber patches allows them to be utilized in a wide spectrum of industries. Within the apparel sector, these patches serve as a powerful tool for creating distinctive designs on clothing. They play a key role in enhancing brand recognition and injecting a personalized element into garments, moving beyond simple functionality to become integral design features.

You’ll frequently find them adorning fashion accessories such as handbags and wallets, as well as practical items like backpacks and hats, adding a touch of visual interest and brand identity.

Beyond the realm of clothing and accessories, rubber patches extend their utility to promotional campaigns. Businesses often incorporate custom rubber patches into promotional giveaways. This strategy proves effective in boosting brand awareness and crafting memorable items that customers are likely to retain and value.

Furthermore, rubber patches hold significant importance in sectors like the military and sports. In these contexts, they are used for clear identification and decorative purposes, effectively displaying unit affiliations in the military or proudly showcasing team logos in sports. Their robust nature also makes them a practical choice for outdoor gear, where durability and resilience are paramount.

2. Designing Your Custom Rubber Patch

2.1 Choosing the Right Shape and Size

Rubber patches offer a variety of shapes, including standard circles and squares or custom shapes tailored to your specific design. Standard sizes range from small (1 inch) to large (4 inches or more). Very large custom shapes may present manufacturing limitations.

Consider the patch’s intended use when selecting size; smaller patches are suitable for clothing while larger ones may be better for bags or jackets. Size and shape influence the final product’s visual impact and practical usability. Balance aesthetic preferences with functional needs to achieve optimal results.

2.2 Selecting Colors and Design Elements

When designing your patch, it is highly recommended to use pantone colors to ensure accurate and consistent color reproduction across different production runs and materials. While more colors enhance detail, fewer colors (generally under 5) usually reduce costs. Design elements like text, logos and borders add visual interest. 2D designs are simpler and 3D designs add depth and texture. For complex designs requiring precise color matching, Pantone is recommended. The fewer colors used generally yields cost savings in production.

2.3 Choosing the Right Backing for Your Patch

Selecting the appropriate backing for your rubber patches is a crucial step in ensuring they are both functional and aesthetically pleasing for their intended application. A variety of backing options are available, each designed to meet different attachment needs and garment types.

For applications requiring a permanent and highly secure attachment, particularly on clothing items that will undergo frequent washing or heavy use, sew-on backings are often the most reliable choice. These backings provide exceptional durability, ensuring the patch remains firmly affixed over time. While they require a bit more effort to apply initially, the longevity they offer makes them a worthwhile investment for items where patch security is paramount.

Adhesive backings, on the other hand, offer a quick and straightforward application method. They are ideal for temporary applications or situations where sewing is not feasible. However, it’s important to consider their limitations.

Adhesive backings may not be as permanent as sew-on options and their effectiveness can vary depending on the material they are applied to. Factors like fabric texture and environmental conditions can influence their long-term adhesion.

For situations demanding versatility and reusability, Velcro backings present an excellent solution. These backings allow for patches to be easily attached and removed, offering flexibility for items where patches might need to be changed or swapped out regularly. This is particularly useful for customizable apparel or items where branding might need to be updated.

Lastly, magnetic backings cater to a very specific application: attachment to metal surfaces. While less common in clothing, they can be useful for promotional items intended for refrigerators, metal boards, or other metallic surfaces. The strength of the magnetic backing should be considered based on the intended use and the weight of the patch.

Ultimately, the best backing option hinges on the intended use of your rubber patches, the type of garment or item they will be attached to, and the desired level of permanence and flexibility. Carefully considering these factors will ensure you select a backing that provides both secure and lasting attachment, perfectly complementing your patch design.

2.4 Exploring Special Design Features

Consider glow-in-the-dark or reflective features to enhance visibility and appeal. Glow-in-the-dark patches are ideal for low-light conditions while reflective patches enhance safety and visibility in dark environments. Adding these specialized features enhances the impact and usefulness of your rubber patch.

3. Partnering with a Manufacturer for Rubber Patch Production

3.1 Finding a Reliable Patch Manufacturer

Selecting a reputable and experienced patch manufacturer with a proven track record of producing high-quality patches is crucial. Research manufacturers online, checking websites and online reviews. Evaluate potential manufacturers based on factors such as their experience, reputation, pricing structure, minimum order quantities (MOQs), turnaround time and customer reviews. Prioritize manufacturers with proven track records and positive feedback.

3.2 The Ordering Process

The ordering process typically begins with submitting a quote request, including your design specifications and desired quantities. After review, the manufacturer will provide a quote. A digital mockup will be presented for your approval. Revisions can be made to ensure the final product matches your expectations before proceeding to the final order. Maintain clear communication throughout the process to address any questions or concerns.

3.3 Understanding Pricing and Turnaround Time

Several factors influence the final pricing of your rubber patches, including the size, design complexity, quantity ordered, chosen backing and inclusion of special features. Larger patches, intricate designs and smaller order quantities generally command higher prices. Turnaround time varies depending on the manufacturer’s workload and the complexity of the design. Expect estimates from several manufacturers before committing.

4. The Rubber Patch Manufacturing Process

4.1 Mold Creation

The creation of accurate molds is paramount for high-quality rubber patches. Precision CNC (Computer Numerical Control) engraving is commonly used to create metal molds with exceptional detail. The accuracy of the mold directly impacts the final patch’s quality to ensure precise reproduction of your design. A well-made mold is crucial for consistent production of high-quality patches.

4.2 Material Preparation and Pouring Liquid

Liquid PVC or silicone, combined with color pigments, forms the base material for rubber patches. The material is carefully prepared to ensure consistent color and texture throughout the batch. Layered pouring techniques, followed by heating and curing processes, are employed to solidify the material and prevent color mixing. Precise material handling is critical.

4.3 Adding the Backing and Finishing Touches

Once the rubber patch is cured, the chosen backing material is applied. Excess material is then carefully trimmed to create a clean, professional finish. This ensures a neat appearance and precise sizing for each patch. This stage completes the manufacturing process, leaving each patch ready for packaging.

4.4 Quality Control and Shipping

Rigorous quality checks are performed throughout the manufacturing process. A final inspection ensures that all patches meet the specified quality standards before packaging and shipment. The manufacturer usually provides a sample patch for customer approval prior to mass production. This assures quality and minimizes discrepancies. Quality control measures ensure consistency in patch quality, shape, color and backing.

5. Alternatives to Rubber Patches

5.1 Heat Transfer Labels

Heat transfer labels provide a versatile alternative to rubber patches, particularly suitable for intricate designs or direct application to fabric. These labels offer vibrant color reproduction and fine detail capabilities, making them ideal for logos with complex elements or small text. Application requires a heat press for optimal adhesion to the fabric. Their flexibility in design and relatively easy application process makes heat transfer labels an attractive alternative to rubber patches, particularly when dealing with intricate designs or needing a wider range of color options.

5.2 Woven Labels

Woven labels present a classic and durable branding solution for clothing and accessories. Known for their high-quality construction and professional look, woven labels offer excellent longevity and a timeless aesthetic. They are commonly used for apparel, bags and other similar items. They are a popular choice for high-end apparel and items requiring long-lasting branding. These labels are typically rectangular or square but can be custom-shaped.

5.3 Other Patch Options

Besides rubber patches, several other patch types exist. Embroidered patches offer a raised, textured look and feel suitable for logos with intricate stitching detail. Printed patches provide a more affordable and flexible option, ideal for simpler designs and high-volume orders. Chenille patches offer a soft, plush texture with their designs rendered in raised loops of yarn.

6. FAQs about How to Make Rubber Patches

6.1 Can I make rubber patches at home?

Producing rubber patches at home is generally not feasible. The process requires specialized equipment, including CNC machines for mold creation and precise temperature-controlled environments for curing the materials. Professional manufacturers possess the necessary resources and expertise for efficient and high-quality patch production.

6.2 What is the minimum order quantity?

Minimum order quantities vary depending on the manufacturer. Typical MOQs range from 50 to 100 pieces though some manufacturers may offer smaller runs for an additional surcharge. Confirm the MOQ with your chosen manufacturer before proceeding with the order. Larger orders frequently result in lower per-unit costs.

6.3 How long does production take?

Production time for rubber patches typically ranges from two to four weeks, depending on the complexity of the design and the order quantity. More intricate designs and larger orders generally require longer production times. Confirm estimated lead times with your chosen manufacturer.

6.4 What design file format is needed?

For optimal results, submit your design in a vector format such as AI, EPS or PDF. Vector formats preserve the sharpness and detail of your design at any size crucial for producing high-quality patches. Raster formats (like JPG or PNG) may lose resolution during scaling. Consult with the manufacturer for specific file specifications.

6.5 How do I care for rubber patches?

To maintain the quality and longevity of your rubber patches, avoid exposure to harsh chemicals and excessive heat. Regularly cleaning the patch with a damp cloth is recommended. Avoid harsh scrubbing which could damage the patch. Proper care ensures the patch remains in excellent condition.

7. Packlove – Providing Services for Rubber Patch Creation

7.1 Value Booster Kit Branding/packaging solution

Enhance your brand presentation with our Value Booster Kit, a comprehensive packaging solution ideal for small businesses and entrepreneurs. This kit includes a variety of customizable items such as stickers, tissue paper and thank you cards to elevate your product packaging and create a memorable customer experience. These items are easily personalized with your logo and branding.

7.2 Woven Labels, Heat Transfer Labels, Rubber Patches

Customize your apparel and accessories with our high-quality woven labels, heat transfer labels and rubber patches. We offer a wide range of customization options and utilize durable, premium materials to ensure lasting quality and a professional finish for your products. Our printing techniques offer vibrant colors and crisp details.

7.3 Zipper Bags, Poly Mailers

Protect and ship your products effectively with our range of zipper bags and poly mailers. These packaging solutions offer varying sizes and materials, accommodating a variety of product types and shipping needs. Our durable bags and mailers ensure your products arrive safely.

Zipper bags, available in food-grade materials, provide excellent protection for small items, maintaining freshness for food or protecting non-food items from moisture and dust. Poly mailers, often made from durable, tear-resistant materials like polyethylene, offer a lightweight yet protective packaging solution ideal for shipping a wide range of products, from clothing to books. Both choices offer secure, tamper-evident packaging options depending on specific product needs.

7.4 Contact Us Website, email, phone number

Connect with our team to discuss your custom printing and packaging needs. Visit our website at https://mypacklove.com/ or contact us directly via email at [email protected] or call us at +84 363615867. We’re here to assist you in creating the perfect packaging and branding solutions.

Read more:

Creating custom rubber patches involves several key steps: designing your patch, selecting materials and backing, choosing a reliable manufacturer, and overseeing the production process. Careful consideration at each stage ensures your vision translates into a high-quality product. Finding a reliable manufacturer is essential for consistent quality and timely delivery. Whether for personal use or business branding, custom patches offer a durable and memorable way to personalize items and convey messaging. Start your patch project today!