Clothing Size Labels: Small Brands US Market Guide

Understanding clothing size labels goes far beyond just complying with basic requirements. For small apparel businesses, mastering this element is a strategic move that impacts customer satisfaction, profitability, and brand perception.

his guide provides comprehensive insights into why size labels matter, the various types and materials available, design best practices, placement strategies, navigating international sizing complexities, and avoiding common pitfalls. By the end, you’ll know how to make informed decisions about size labeling that align with your brand’s quality standards and business goals, particularly when targeting the discerning US market.

1. Why size labels are more than just a tag: Strategic impact for your apparel business

Size labels play a critical, often underestimated, role in the success of an apparel brand, especially in the competitive retail landscape. Their impact extends far beyond simply stating a size; they are integral to the customer experience and influence key business outcomes. Consider these strategic effects:

- Influencing purchase decisions: In the realm of online shopping and e-commerce platforms, where customers cannot physically try on garments, clear and accurate sizing information is paramount. Well-defined sizing reduces customer hesitation, provides confidence, and directly encourages conversion. Ambiguity, conversely, often leads to abandoned carts.

- Minimizing costly returns: Incorrect fit is a primary driver of returns in the apparel industry. Each return incurs significant costs: return shipping expenses, labor for inspection and restocking, and potential revenue loss if the item cannot be resold at full price. Precise size labeling minimizes these returns, directly improving profitability and customer satisfaction.

- Building brand identity and trust: Consistent, professional-looking size labels across your entire product line signal attention to detail and quality. This consistency reinforces your apparel brand identity and builds trustworthiness over time. A thoughtfully chosen label, even for sizing, contributes to the overall perceived value of the garment.

- Maintaining competitiveness: In saturated markets, particularly the US, customer expectations for product information are high. Providing clear, easily understandable sizing isn’t just helpful; it’s necessary to compete effectively. Brands that neglect this detail risk appearing less professional and may lose customers to competitors who prioritize clarity. Investing in good labeling is investing in your brand’s competitive position.

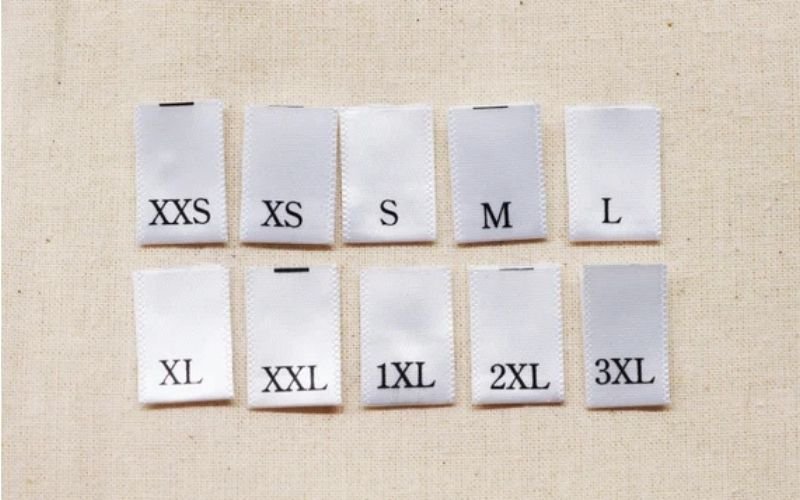

1.1. Types of size labels: Matching form and function

Choosing the right type of size label involves balancing aesthetics, comfort, durability, and cost-effectiveness. Understanding the different label types helps match the label to the garment and brand positioning. Here’s a breakdown of common garment labels:

Woven labels: These are created by weaving threads together on a loom, resulting in a durable, integrated design.

- Varieties include: Damask (high density, good for fine details), Taffeta (more basic, cost-effective weave), and Satin (smooth surface, slight sheen, softer feel).

- Pros: High perceived value, very durable and wash-resistant, convey a professional, premium look.

- Cons: Typically higher unit cost, often require higher minimum order quantities (MOQs), potentially longer production lead times, edges can sometimes feel scratchy if not finished properly (e.g., ultrasonic cutting).

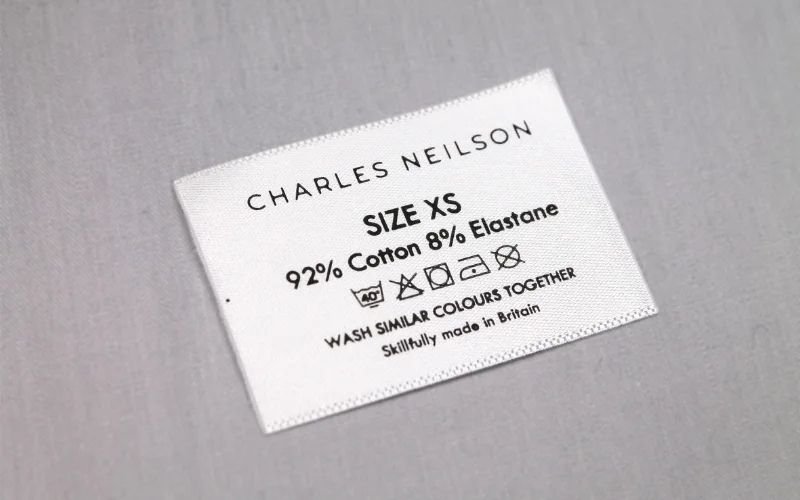

Printed labels: These involve printing size information onto a base material strip, which is then cut and sewn into the garment.

- Common materials: Satin (very soft, smooth), Cotton (natural feel), Nylon/Polyester (durable, economical).

- Pros: Excellent for capturing very fine details or complex logos alongside the size, generally softer feel (especially satin and cotton options), often lower cost per unit compared to woven, typically faster turnaround times and lower MOQs.

- Cons: Ink durability can vary depending on print method, material, and washing frequency (though quality printing is very resilient), may be perceived as less luxurious than woven labels by some consumers.

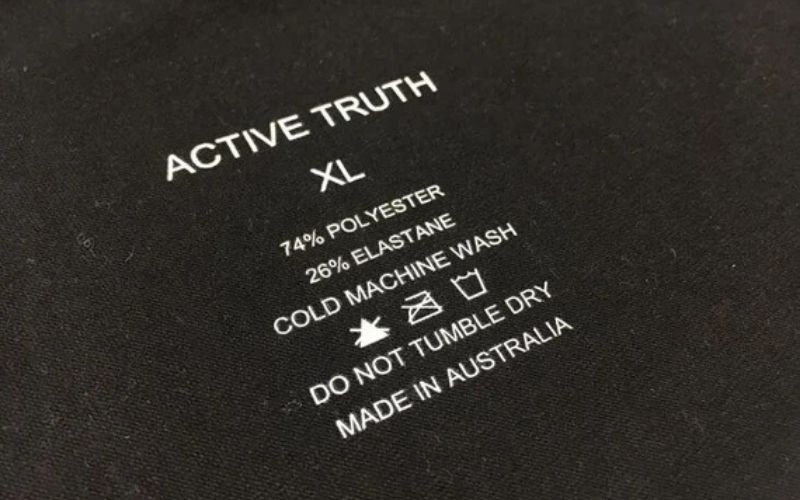

Heat transfer labels (tagless labels): These labels are printed onto a special release paper or film and then transferred directly onto the fabric using heat and pressure.

- Pros: Offer maximum comfort as there’s no physical tag (“tagless”), provide a clean, integrated look, ideal for performance wear, basics, children’s clothing, and garments worn close to the skin.

- Cons: Requires a heat press for application (an extra step and equipment consideration in the manufacturing process), durability can depend heavily on the ink quality, application process, and the type of fabric (may crack or peel over time, especially with heavy stretching or harsh washing), potentially less perceived value than a physical tag for some garment types.

1.2. Common label material deep dive

The material chosen for your size fabric labels significantly impacts both the wearer’s experience and the label’s longevity. Understanding the properties of common options helps in selecting the best fit for your garment and brand.

- Satin (polyester): Known for its smooth, slightly glossy surface, satin offers exceptional softness against the skin. This makes it an excellent label material choice for items where comfort is paramount, such as necklines of shirts and dresses or intimate apparel. Its smooth face is also ideal for high-detail printed labels. While derived from polyester, its weave structure gives it that characteristic soft feel.

- Cotton: Offering a natural, breathable feel, cotton labels align well with brands emphasizing organic materials or an eco-conscious image. Cotton provides a distinct matte appearance and soft touch. While comfortable, it’s worth noting that pure cotton labels might exhibit less durability compared to synthetic options over extensive washing cycles and could be more prone to slight shrinkage or fraying if not finished properly. Cotton is suitable for printing.

- Polyester/Taffeta: This category represents durable and cost-effective choices. Standard polyester labels are known for their excellent durability, resistance to repeated washing, and minimal shrinkage. Taffeta, a type of polyester weave, is often used as a base for simpler woven or printed labels due to its affordability and sturdiness, though it can sometimes feel stiffer than satin. Polyester, in general, is highly versatile and widely used for both printed and basic woven fabric labels.

Expert insight: The selection of a label material extends beyond technical specifications; it’s intrinsically linked to brand perception and the intended use of the garment. A luxury brand might favor the premium feel of woven damask or the smooth softness of high-quality satin to reinforce its image.

Conversely, brands focused on basics, performance wear, or budget-friendly lines might opt for durable printed polyester or tagless heat transfers for practicality and cost-efficiency. Consider the garment’s function – rugged outerwear demands a label with high durability like polyester, while a delicate blouse benefits from the gentle touch of satin or cotton.

1.3. Standard size label dimensions: Industry benchmarks & considerations

While there are no strict universal rules for size label dimensions, certain sizes are commonly used within the industry for sew-in labels. It’s crucial to view these as guidelines rather than mandates, as the ideal dimension depends on the garment, placement, and label design. Common examples, often expressed in millimeters (width x length before folding), include:

- Loop Fold/Center Fold: Frequently seen sizes might be 15x50mm or 20x60mm (flat), which fold in half to become 15x25mm or 20x30mm (visible finished size) respectively.

- End Fold: Sizes like 10x40mm or 15x50mm (flat) are common. After folding the ends under for sewing, the visible area is slightly smaller than the flat dimension.

- Straight Cut: Dimensions vary widely, perhaps 20x30mm or larger, depending on whether it’s sewn on all four sides or just along the top edge.

Understanding common label folds is key:

- Loop Fold / Center Fold: The label is folded in half with the size info on the front (and potentially back). The raw edge is sewn into a seam, leaving a clean folded edge visible.

- End Fold: Both short ends of the label are folded under (either inwards or outwards) and the label is typically sewn down flat along these folded ends.

- Straight Cut: The label is cut with no folds, often heat-sealed to prevent fraying. These are typically sewn flat onto the garment, either around all edges or just across the top.

The primary consideration when choosing dimensions is balancing readability with comfort. The size information must be large and clear enough to be easily read by the customer. However, an excessively large label, especially in sensitive areas like the neck, can cause irritation or add unnecessary bulk. The intended placement often dictates the acceptable size – a label inside a waistband can often be larger than one placed at the back neck.

2. Designing effective size labels: Clarity and brand alignment

Effective label design for size labels prioritizes clear communication and aligns with your overall brand aesthetic. The goal is to provide essential information quickly and easily to the customer.

Prioritize readability: This is paramount. Opt for simple, clean fonts; sans-serif typefaces (like Arial, Helvetica, or Calibri) are often the best choice for clarity, especially at small sizes. Ensure the size (measurement) text is large enough to be read comfortably without squinting. Crucially, maximize contrast between the text and the color base of the label. Classic combinations like black text on a white or cream background, or white/light grey text on a black or navy background, offer excellent readability. Avoid low-contrast pairings or overly stylized fonts that sacrifice legibility.

Focus on essential information: The primary purpose of a size label is to convey the size (measurement). Keep the text/information displayed focused on this critical piece of data. Resist the temptation to clutter the label with logos, slogans, or other non-essential elements.

Consider label integration: It’s possible to combine size information with care labels or brand labels onto a single tag.

- Pros: This reduces the number of labels needing to be sourced and sewn into the garment, potentially lowering costs and streamlining production.

- Cons: Integrated labels can become quite large, long, or visually busy, which might compromise the clarity of the size (measurement). There’s also a practical consideration: care labels might need updates based on fabric changes more frequently than basic sizing. Careful label design is essential if pursuing this route to ensure all information remains distinct and legible.

Choose and maintain a consistent sizing system: Decide whether your clothing brand will primarily use an alphabetical sizing system (S, M, L, XL) or a numerical one (US clothing sizes like 2, 4, 6, 8). Consider your specific target market and what system they are most familiar with. The most critical aspect is consistency across your product range to avoid confusing customers.

3. Best practices for size label placement & attachment

Strategically placing and attaching size labels significantly impacts both comfort and the perceived quality of the garment.

Common placements for size labels include:

- Center back neck: A traditional location for shirts, dresses, and tops, offering high visibility when the garment is viewed on a hanger or tried on. However, this can be an area of sensitivity for some wearers.

- Side seam: Often placed lower down in the seam of shirts, tops, dresses, and sometimes pants. This placement generally minimizes skin contact and irritation potential, enhancing comfort.

- Waistband: The logical placement for pants, skirts, and shorts, usually sewn into the inner waistband seam.

The type of garment heavily dictates the appropriate placement. For instance, placing a label at the back neck of pants would be unconventional and impractical.

Expert tip: For garments intended to be worn directly against the skin, prioritize comfort above all else. Consider using very soft label materials (satin, cotton) placed in a low-friction area like the side seam. Alternatively, heat transfer labels (tagless) offer an excellent solution.

The attachment method also plays a role:

- Sew-in labels: Various sewing folds affect how the label integrates with the garment.

- Loop Fold/Center Fold: Typically sewn into a seam during construction.

- End Fold/Mitre Fold: Often sewn onto the surface of the garment or top-stitched into a facing or waistband.

- Heat transfer labels: These require a different process, using a heat press to bond the label directly to the fabric, eliminating the need for sewing.

Choosing the right combination of placement and attachment method ensures the label is secure, legible, and comfortable for the end-user.

Selling apparel internationally, particularly to the US market, introduces the common challenge of sizing differences. International sizes (such as US, UK, EU, Asian) often lack a direct, one-to-one conversion, creating potential confusion for customers involved in international trade. Effectively managing this requires clear communication strategies for your garment tags and online presence.

Consider these approaches for handling multiple sizing systems:

- Dual/triple sizing on labels: Displaying multiple size equivalents (e.g., “M / US 8 / EU 40”) directly on the label seems like a straightforward solution. However, this can quickly clutter the label, potentially making it difficult to read and confusing if not executed with a very clean design.

- Region-specific labels: Producing labels specific to each target region (e.g., labels showing only US clothing sizes for the US market) provides the clearest information for customers in those areas. While ideal for clarity, this approach often presents logistical complexities and higher costs (managing separate inventories, increased minimum order quantities (MOQs)) that can be challenging for small business apparel brands.

- Prioritize your primary market: A practical strategy is to clearly and prominently display the sizing system for your main target market (e.g., US clothing sizes if primarily selling to the US). This ensures clarity for the majority of your customers.

Crucial recommendation: Regardless of the on-label approach, strongly supplement your physical garment tags with a detailed online sizing chart or measurement guide. This is the most reliable way to bridge the gap. Make this chart easily accessible on your e-commerce platform product pages and base it on actual garment measurements.

- Make this chart easily accessible on your e-commerce platform product pages.

- Consider adding a QR code on hang tags or care labels that links directly to the guide.

Most importantly: Base your sizing chart on actual garment measurements, not just generic size conversions. Provide measurements for key points (e.g., chest, waist, hips, length, inseam) in both inches and centimeters (cm) to cater to diverse customer preferences.

Expert note: Detailed online measurement guides are essential for success on e-commerce platforms, especially in markets like the US. They reduce guesswork, manage customer expectations, and significantly lower the rate of costly returns – a critical factor for the profitability of small business apparel ventures.

5. Practical considerations & avoiding pitfalls for small businesses

For small business apparel brands, navigating the operational aspects of sourcing and implementing size labels requires careful planning. Addressing practical considerations early can prevent costly mistakes and ensure labels enhance, rather than detract from, your products.

- Finding reputable suppliers: Partnering with reliable label suppliers is crucial. Don’t just look at price; seek suppliers with demonstrated expertise in apparel labeling. Always request physical samples to assess quality, feel, and print clarity firsthand. Check online reviews or ask for references. Discuss their understanding of different materials and attachment methods relevant to your specific garments. A good supplier acts more like a consultant during the selection process.

- Understanding MOQs and budgeting: Be aware that label suppliers typically have minimum order quantities (MOQs) – the smallest number of labels you can order at one time. These quantities vary significantly based on the label type (woven often have higher MOQs than printed or heat transfer) and the supplier. Obtain quotes early in your product development cycle and factor these costs accurately into your overall garment costing and pricing strategy. While cost is a factor, remember that the cheapest option isn’t always the best value; consider durability and perceived quality.

- Ensuring label durability: The longevity of your size label directly impacts customer perception and brand trustworthiness. Before committing to a large order, perform wash tests. Apply sample labels (using the intended attachment method) to swatches of your actual garment fabric and run them through multiple home laundry cycles that mimic typical consumer use. Check for fading, fraying, peeling (for heat transfers), or any degradation that could reflect poorly on your brand. This step validates label durability in real-world conditions.

- Common mistake: Sacrificing quality for minor savings: A frequent pitfall for emerging brands is opting for the absolute cheapest label solution to save a few cents per garment. Often, this means compromising on material softness, print clarity, edge finishing, or label durability. This minor upfront saving can lead to negative customer experiences (scratchy labels, faded information) and ultimately damage brand perception and customer satisfaction – a cost far greater than the initial saving.

- Compliance context: While the size information itself isn’t federally mandated content in the US, other critical details often share label space or are required nearby. Remember that regulations like the FTC Regulations (Federal Trade Commission rules) governing apparel labeling, including the Textile Fiber Products Identification Act (TFPIA), do mandate clear disclosure of fabric content and country of origin. Ensuring all your apparel labeling is accurate and compliant is simply part of professional practice and builds brand trustworthiness. Getting size labels right should be part of a holistic approach to compliant and informative labeling.

6. Related questions

6.1 Can I combine size information with care instructions on one label?

Yes, combining size details with care instructions onto a single label is a common practice, often chosen for cost savings and production efficiency. The primary advantage is needing to source and attach only one label instead of two.

However, the main drawback is that combined labels can become quite long or visually cluttered, potentially making it harder for customers to quickly find either the size or the washing guidance. Effective integration requires careful label design to maintain clarity for all necessary information.

6.2 What are typical minimum order quantities (MOQs) for custom size labels?

Minimum order quantities (MOQs) for custom size labels vary considerably depending on the specific label supplier and the type of label being ordered. Generally, woven labels tend to have higher MOQs compared to printed labels or heat transfer labels. While broad ranges might span anywhere from 500 pieces to several thousand pieces per size/design, it is essential to request specific quotes from potential suppliers, as their requirements can differ significantly based on their production capabilities and pricing structures.

6.3 How do I ensure my size labels are comfortable and don’t irritate the skin?

Ensuring label comfort involves several factors. Firstly, consider the label material: opting for inherently soft materials like satin or cotton, or choosing tagless heat transfer labels, significantly reduces the potential for irritation. Secondly, strategic placement helps; positioning the label in a side seam rather than the sensitive back-neck area is often preferred. Finally, the finishing of the label matters; ensure woven labels have smooth, cleanly cut edges (ultrasonic cutting is often used for softness) and that printed labels don’t have sharp corners.

6.4 Should I use ‘Made in…’ information on the size label?

While disclosing the country of origin (e.g., “Made in USA” or “Made in Vietnam”) is a legal requirement in the US under FTC Regulations, this information is typically placed on the main brand label, the dedicated care label, or sometimes on a separate small tag sewn into a seam.

It is not usually the primary information featured on a label solely dedicated to indicating size, unless it’s part of a larger, integrated label design that combines branding, care, size, and origin information. The main size label’s focus should remain on clearly communicating the garment size.

Read more:

In summary, well-executed size labels are far more than a minor detail; they are essential communication tools that profoundly influence customer satisfaction, minimize costly returns, and significantly bolster your apparel brand’s perceived value and professionalism. Taking the time to select appropriate materials, design for clarity, choose strategic placements, and navigate sizing complexities demonstrates a commitment to quality that resonates with customers.

Investing thought and appropriate resources into getting clothing size labeling right is not an expense, but a crucial investment in your brand’s growth and reputation. For small businesses, particularly those selling online or targeting discerning markets like the US, clear and comfortable sizing is fundamental to building trust and achieving long-term success.