What is Screen Printing? Concept, Process and Benefits

Screen printing, also known as silkscreening, is a versatile and widely used printing technique capable of producing vibrant, durable designs on a variety of materials. From graphic t-shirts and posters to industrial labels, its applications are vast.

But what exactly is screen printing? This article will delve into the core concept behind this method, walk you through the step-by-step process involved, and highlight the key benefits that make it a popular choice for artists, businesses, and manufacturers alike.

1. Unpacking Screen Printing: The Core Concept for Fabric & More

1.1 Defining Screen Printing (Also Known as Serigraphy or Silk Screen Printing)

Screen printing is a versatile printing technique that utilizes a mesh screen stretched tightly over a frame, ink, and a stencil (a design-blocking layer) to transfer an image onto a surface, known as the substrate. While commonly called screen printing, you might also hear the terms silk screen printing or serigraphy; these names all refer to the same fundamental method where the stencil makes certain areas of the screen impermeable, allowing ink transfer only through the open mesh corresponding to the design.

1.2 The Basic Idea: How Stencils and Ink Create Your Design on Textiles

The core principle of stencil printing involves creating a barrier on the mesh screen. This stencil blocks the ink in the ‘negative’ space – the areas not part of the design. The open mesh areas, conversely, represent the positive image.

When ink is pushed across the screen, it passes only through these open areas, creating the design imprint onto the material positioned underneath. This technique is highly effective for fabric printing, particularly on textiles common in the apparel industry like cotton t-shirts, but its applications extend to other materials relevant for branding, such as certain types of packaging.

2. The Screen Printing Process Step-by-Step: From Design File to Finished Garment

2.1 Artwork Prep – Creating the Film Positive

The process begins with your artwork design. The digital design is printed in solid black onto a transparent sheet, typically acetate, creating what’s called a film positive. This film acts as the master template for making the stencil on the screen; essentially, the film facilitates the design transfer to the screen emulsion. For designs featuring multiple colors, a separate film positive is required for each distinct color, a process known as color separation.

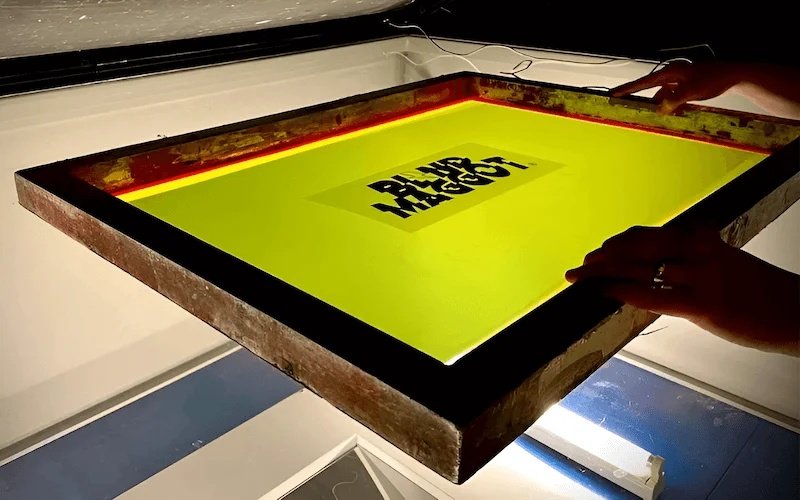

2.2 Coating the Mesh Screen with Photo Emulsion

A clean mesh screen, composed of woven mesh stretched tightly on a screen frame, is evenly coated with a light-sensitive liquid called photo emulsion. This step must be performed in a light-safe environment, typically under yellow light, as the emulsion reacts to UV light. The coated screen is then left to dry thoroughly in complete darkness.

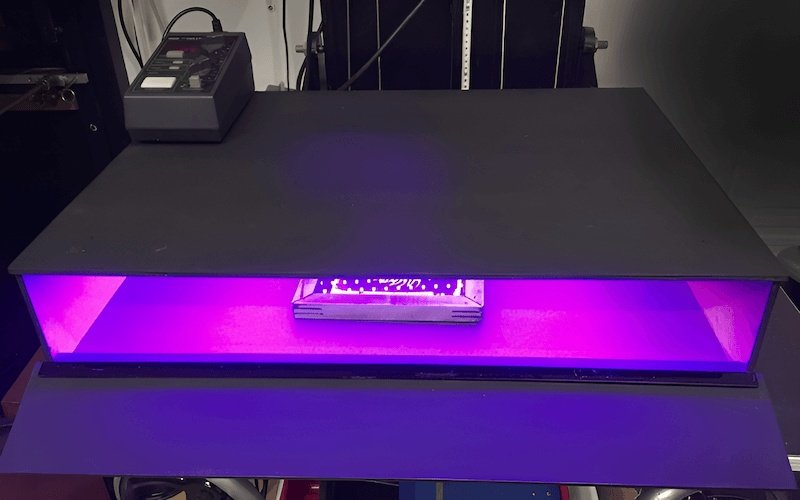

2.3 Exposure – Burning the Stencil with UV Light

Once the emulsion is dry, the film positive is carefully positioned onto the coated screen. This assembly is then placed in an exposure unit and subjected to a strong UV light source. The UV light hardens the photo emulsion everywhere except for the areas shielded by the black design on the film positive. This selective hardening is the crucial step in the stencil creation process.

2.4 Washout – Revealing the Design on the Screen

Following exposure, the screen is taken to a washout booth. Water, often under pressure, is used to rinse the screen. The emulsion that was blocked from the UV light by the film positive remains soft and water-soluble, so during the washout, these areas dissolve away.

This leaves openings in the hardened emulsion precisely in the shape of the design. These open areas in the mesh screen constitute the stencil through which ink will later pass. The screen is then thoroughly dried before moving to the press.

2.5 Press Setup & Registration

The finished screen (or screens, for multi-color jobs) is securely mounted onto a printing press. For multi-color prints, precise alignment, known as registration, is critical. Each screen, representing a different color layer in the design, must be positioned exactly so that the colors print in their intended locations relative to each other, forming the complete image.

This involves a careful color layering system. Presses range from simple manual press setups suitable for smaller operations to sophisticated automatic press machines designed for high-volume production.

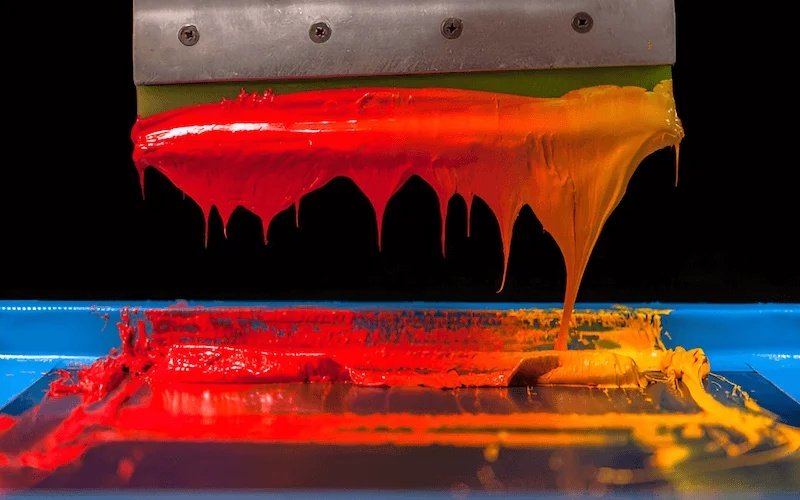

2.6 Ink Application – The Role of the Squeegee

The item to be printed, the printable substrate (like a t-shirt, label fabric, or poly mailer), is placed onto the press pallet. A quantity of ink is applied along one edge of the inside of the screen. A rubber squeegee, a firm rubber blade set in a handle, is then pulled (or pushed, depending on technique) across the screen’s surface with consistent pressure.

This ink application technique forces the ink through the open mesh areas of the stencil and onto the substrate positioned directly below.

2.7 Curing – Making the Print Permanent

After the ink is applied, the printed item must undergo a curing process to ensure the design becomes permanent and washable. This typically involves passing the item through a curing unit, most often a conveyor dryer that uses heat.

The heat curing procedure dries the ink and chemically bonds it to the fibers of the substrate. Proper curing is essential for print durability and wash-fastness, preventing the print from cracking, peeling, or fading with use and laundering.

3. Why Screen Printing Excels for Apparel Brands

3.1 Unmatched Color Vibrancy & Opacity, Even on Dark Fabrics

Screen printing inks, particularly plastisol ink, are renowned for their high opacity (ability to block out the color underneath). They deposit a relatively thick layer of ink, resulting in exceptional color vibrancy quality. This makes screen printing highly effective for achieving bright, bold colors that maintain their intensity even when printed on dark fabrics like black or navy apparel, tags, or mailers – a common challenge for some other printing methods where opaque ink coverage is crucial.

3.2 Superior Durability: Prints That Withstand Wear and Washing

A key advantage for apparel brands is the exceptional durability of properly cured ink in screen prints. The ink forms a strong bond with the fabric fibers, resulting in prints that exhibit excellent wash resistance and are less prone to cracking, peeling, or significant fading over time, even with repeated wear and laundering. These print longevity characteristics make screen printing a reliable choice for items intended for long-term use.

3.3 Cost-Effectiveness for Batch Production

While screen printing involves setup cost for each screen (one per color), the process becomes highly cost-effective for batch production. As the quantity of items increases (large volume), the cost per unit decreases significantly.

This batch-oriented nature makes screen printing an economical choice for producing items like custom labels, care labels, promotional t-shirts, staff uniforms, or any apparel item needed in quantities typically ranging from dozens to thousands.

3.4 Versatility in Ink Types & Effects

Screen printing offers flexibility through various ink types. The most common for apparel are plastisol ink (known for brightness, opacity, durability, and a slightly raised tactile feel) and water-based ink (which dyes the fabric more, resulting in a soft hand feel and better breathability, often preferred for lighter garments or vintage looks, with eco-friendlier options available).

Beyond these, screen printing accommodates specialty inks like puff (3D effect), metallic, glitter, high-density, and reflective inks, allowing for creative branding and unique finishes.

4. Potential Downsides: When to Consider Alternatives

4.1 Setup Time & Cost Implications for One-Offs or Very Small Runs

The process of preparing screens (artwork separation, film output, coating, exposure, washout) involves time and materials. This inherent setup cost per screen makes screen printing less economical for producing one-offs or very small orders (often considered fewer than 12 or 24 pieces per design, though this varies by print shop). For single custom items or extremely limited runs, other methods might be more suitable.

4.2 Limitations with Highly Detailed Photographic Prints

While screen printing can achieve impressive detail using screens with a high mesh count, reproducing photographic prints with very smooth complex gradients and a vast spectrum of subtle color variations can be challenging.

Achieving photorealistic quality often requires specialized techniques (like simulated process printing) and may still not match the fidelity possible with methods like digital printing (Direct-to-Garment or DTG), which excel at rendering fine details in photos.

4.3 Minimum Order Quantities Often Apply

Due to the setup effort and costs involved, most commercial printing shops specializing in screen printing establish Minimum Order Quantity (MOQ) requirements. This means they typically won’t accept orders below a certain number of pieces per design. This is a standard practice for this printing method, and small businesses should factor potential MOQs into their planning when sourcing screen-printed goods.

5. Screen Printing vs. The Alternatives: Making the Right Choice

5.1 Screen Printing Compared to Digital Printing (DTG)

Choosing between screen printing and digital printing (DTG) often depends on the specific project needs. Here’s a comparison:

- Best Use Case: Screen printing excels at larger runs (typically 24+ pieces), designs with bold graphics or limited colors, and achieving high opacity on dark garments. DTG is ideal for small runs (even single items), photorealistic images, designs with many colors or complex gradients, and quick turnaround on small orders.

- Color Vibrancy: Screen printing generally offers superior color vibrancy and opacity, especially with plastisol inks on dark fabrics. DTG provides good color representation using CMYK ink mixing, but vibrancy on darks can sometimes require a white underbase and may appear slightly less intense than screen print.

- Durability: Properly cured screen prints are known for excellent durability and wash-fastness. DTG print durability is generally good and improving, but can vary depending on the machine, inks, pretreatment, and fabric; it may sometimes be slightly less robust than a thick plastisol screen print over long-term washing.

- Feel: Screen printing feel varies; plastisol sits slightly on top of the fabric, while water-based inks offer a softer feel. DTG prints typically have a very soft feel as the ink dyes the fabric fibers directly.

- Cost: Screen printing has higher setup costs but a lower cost per piece at volume. DTG has minimal setup, making it cost-effective for small runs, but the cost per piece remains relatively consistent regardless of quantity.

- Setup: Screen printing involves a multi-step screen preparation process for each color. DTG requires primarily digital file preparation and machine setup.

| Feature | Screen Printing | Digital Printing (DTG) |

|---|---|---|

| Best Use | Larger runs (24+), bold graphics, dark fabrics | Small runs (1+), photos, complex colors, quick turnarounds |

| Color | Excellent vibrancy & opacity, esp. on darks | Good (CMYK mix), variable on darks, great for gradients |

| Durability | Excellent when properly cured | Good and improving, can vary |

| Feel | Variable: slight layer (plastisol) or soft (water-based) | Generally very soft, ink integrated into fibers |

| Cost/Piece | Lower at higher volumes | Consistent, better for small runs |

| Setup | More involved (screens per color) | Minimal (digital file prep) |

5.2 Screen Printing Compared to Heat Transfer Printing

Screen printing and heat transfer printing serve different purposes within apparel decoration:

- Best Use Case: Screen printing is favored for high volume runs where durability is paramount (e.g., brand merchandise, uniforms). Heat transfers excel for small runs, individual personalization (like names/numbers on jerseys), applying graphics to difficult-to-print items (hats, bags), and achieving quick turnarounds for simple applications.

- Durability: Screen printing generally offers superior, integrated durability, especially with plastisol ink. Heat transfer durability varies significantly based on the type of transfer used (vinyl, plastisol transfers, sublimation transfers). Some transfers can feel like a distinct layer on top and may be prone to cracking or peeling over time, while others offer better longevity.

- Application Feel: Screen prints can range from a noticeable layer (plastisol) to nearly undetectable (water-based on light fabric). Heat transfers often feel like a distinct layer applied to the garment’s surface, although newer transfer types aim for a softer hand.

- Detail: Screen printing handles graphic detail well. Heat transfers, particularly digital or sublimation types, can reproduce very fine details and photographic images effectively.

- Cost: Screen printing becomes more cost-effective at higher volume. Heat transfers are often more economical for small runs and personalization due to lower setup requirements per design.

6. Common Screen Printing Applications in Your Clothing Business

6.1 Crisp & Durable Neck Labels and Care Instruction Tags

Screen printing is an excellent choice for producing neck labels (both tagless labels printed directly inside the garment and traditional sewn-in fabric labels) and care instruction tags. The method delivers the sharp detail needed for legibility of small text and symbols, combined with the durability required to withstand numerous wash cycles throughout the garment’s life.

This application provides a professional and lasting finish for brand identification and compliance information.

6.2 Branding Poly Mailers and Other Packaging Essentials

Beyond garments, screen printing demonstrates substrate versatility. While potentially requiring specialized inks and setups, this technique can be effectively used for branding certain types of packaging, such as poly mailers or cardboard shippers. Screen printing is particularly suitable for applying simple, bold logos or brand marks where good opaque ink coverage is desired for visibility.

6.3 Producing Consistent Quality for Staff Uniforms or Merchandise Runs

A significant advantage of screen printing for businesses is its ability to deliver consistent quality across large batch production runs. When producing staff uniforms, event merchandise, or retail apparel stock, screen printing ensures that each item features the identical print in terms of color, placement, and quality. This uniformity is crucial for maintaining brand standards and presenting a cohesive brand image.

7. Expert Tips for Optimizing Your Screen Printed Products

7.1 Why Mesh Count Matters: Fine Detail for Tags, Robust Coverage for Hoodies

The mesh count of a screen refers to the number of threads per linear inch (e.g., 110, 160, 230, 305). Understanding mesh tension significance and count helps optimize results. A higher mesh count (like 230-305) uses finer threads with smaller openings, allowing for greater fine detail – ideal for small text on tags or intricate graphics.

However, higher counts deposit less ink. Conversely, a lower mesh count (like 110-160) has larger openings, permitting more ink flow. This achieves better ink coverage and opacity, especially beneficial for printing light colors on dark, heavy fabrics like hoodies, but sacrifices the finest details. Matching mesh count to the design complexity and fabric type is key.

7.2 Choosing Your Ink: Plastisol’s Brightness vs. Water-Based Soft Feel

Making informed ink choices impacts the final look and feel.

- Plastisol Ink: Select this for maximum brightness and opacity, particularly effective on dark garments. Plastisol offers excellent durability and works well for crisp graphics, though it leaves a slightly heavier, more plasticized feel on the fabric surface.

- Water-Based Ink: Opt for this when a soft hand feel and breathable print are desired. Water-based inks penetrate and dye the fabric fibers more, resulting in a print that feels like part of the garment. Ideal for lighter fabrics, vintage aesthetics, or achieving a premium feel. Opacity on darks can be a challenge without an underbase (a preliminary white layer). Some water-based options also offer environmental benefits.

7.3 Simple Artwork Guidelines for Flawless Prints

Providing proper artwork is crucial for achieving high-quality screen prints. Follow these artwork guidelines:

- Use Vector Format: Whenever possible, supply artwork in vector format (files ending in .ai, .eps, or sometimes vector .pdf). Vector graphics scale infinitely without losing sharpness, ensuring crisp edges.

- Outline Fonts: Convert all text to outlines or curves. This prevents font substitution issues if the print shop doesn’t have the specific font used.

- Specify Colors: If precise brand color matching is needed, provide Pantone colors (PMS – Pantone Matching System values) rather than relying on CMYK or RGB values, which can vary in print.

- Ensure Clean Files: Submit artwork that is ‘clean’ and print-ready, meaning it’s appropriately sized, free of stray points or hidden layers, and clearly indicates color separations if applicable. Good graphic design preparation prevents delays and printing errors.

8. Related Questions

8.1 How long does a quality screen print typically last on apparel?

A high-quality, properly cured screen print is known for its excellent durability and can often last for the lifetime of the garment itself. Factors influencing longevity include the quality of the ink used, the thoroughness of the curing process, the type of fabric, and the owner’s washing and drying habits (e.g., washing inside out, avoiding high heat drying can extend print life).

Compared to some other decoration methods, screen printing is generally considered one of the most durable options for apparel due to its washability.

8.2 Can you effectively screen print on polyester or performance fabrics?

Yes, screen printing on polyester, performance fabrics, and synthetic blends is achievable, but requires specific techniques and materials. Standard plastisol inks may not adhere well or can lead to dye migration, where the fabric dye bleeds into the ink color over time (especially noticeable with white ink on red polyester).

To prevent this, printers use specialized inks formulated for synthetics, often containing bleed-blockers or requiring lower curing temperatures. Experienced screen printers understand these nuances and can achieve durable, vibrant prints on these materials.

8.3 What’s a realistic minimum order quantity for screen printing projects?

There isn’t a universal Minimum Order Quantity (MOQ) for screen printing; print shop policies vary widely. MOQs are based on the setup effort required for each design (creating screens for each color). A common starting point for many shops is around 12 to 24 pieces per design and colorway, but it can be higher (50, 100, or more) depending on the shop’s equipment (manual vs. automatic presses) and business model.

For very small quantities, the cost per item can become prohibitively high due to the setup involved. It’s always best to inquire directly with potential print partners about their specific MOQs.

Read more:

Screen printing remains a cornerstone of apparel decoration, valued for its ability to produce vibrant, opaque colors, exceptional durability, and cost-effectiveness at volume. For businesses needing consistent quality across batch runs of merchandise, uniforms, or branded essentials like tags and labels, screen printing is often an ideal choice, especially when bold graphics and longevity are priorities.

However, the setup requirements make it less suitable for very small orders or one-off custom pieces, where digital printing (DTG) might be a better fit. Similarly, for highly detailed photographic reproduction, DTG often provides superior results.

Heat transfers offer solutions for personalization and application on tricky items. Ultimately, the “right” technique depends on aligning the method’s strengths—like screen printing’s vibrancy, durability, and scale economies—with your specific product needs, order quantity, design complexity, and overall brand vision. Understanding these factors allows you to make an informed choice that best serves your apparel business.