What is Shrinkage? Understand Causes, Prevent And Care Tips

Fabric shrinkage is a common experience. Your favorite T-shirt might feel a bit snug after a wash. This change in size, or shrinkage, can be frustrating. But understanding why fabrics shrink is the first step to managing it. Knowing the causes helps you care for your clothes and fabric items better.

It also helps businesses make choices that keep their products looking great. This guide will explain what shrinkage is, why it happens, and how you can prevent or reduce it. We’ll also explore how this affects branding elements like labels and tags.

1. What is fabric shrinkage and why does it matter?

1.1 Defining shrinkage: more than just smaller clothes

Shrinkage is when your fabric or clothes get smaller. This usually happens after you wash them. It’s a natural process for many kinds of fabric. It is not always a sign that something is wrong with the material. This reduction in size is a permanent change.

It’s different from fabric just stretching out for a little while and then going back to its normal size. Many people experience this, so don’t worry if it happens to you. Understanding shrinkage can help you handle it better.

1.2 Why understanding shrinkage is important for everyone

Knowing about shrinkage is useful for everyone.

- For consumers (people buying clothes): If you buy clothes, knowing about shrinkage helps you take good care of them. This means your favorite clothes can last longer and keep fitting you well. It also helps you choose new clothes more wisely at the store. Good garment care starts with understanding your fabric.

- For businesses (designers/manufacturers): If you make or sell clothes or fabric items, understanding shrinkage is very important. It helps in textile quality control and making good quality products. When you control shrinkage, your customers will be happier with what they buy. Happy customers mean a good name for your brand.

Knowing this property of shrinkage helps everyone make better choices. Want to know what really makes fabric shrink and how you can stop it? Keep reading to find out!

2. The science behind shrinkage: what causes fabrics to shrink?

Understanding why fabrics shrink can help you prevent it. Several factors contribute to this common issue.

2.1 The main culprits: heat, moisture, and agitation

The main reasons your clothes shrink when you wash and dry them are heat, moisture (water), and agitation (movement).

Heat (from hot water or a hot dryer):

Heat makes the tiny threads, called fibers, in your fabric relax. After relaxing, they can pull together and get tighter. This makes the fabric smaller. This happens especially with hot water temperature in your washing machine or high temperature in your dryer. Natural fibers like cotton are very sensitive to heat. So, yes, hot water often makes clothes shrink more. Indeed, high heat during washing or drying is a common culprit we’ve seen contribute to unexpected shrinkage in customer items.

Moisture and water absorption:

When fabrics get wet, especially natural ones like cotton or wool, their fibers soak up water and swell. When these wet fibers dry, they can shrink, sometimes ending up smaller than they were before. This process of swelling with water and contracting upon drying is what scientists call ‘hygral expansion’.

Mechanical action (agitation – movement):

This is the rubbing and tumbling movement from your washing machine spinning. It can also happen from wringing clothes hard by hand. All this movement can make the fibers in the fabric rub against each other, tangle up, and pull tighter.

For wool, this is a big deal. Wool fibers have tiny, overlapping scales. When wool gets wet, warm, and is moved around a lot, these scales can lock together. This is called felting. It makes the wool fabric become very thick, dense, and much smaller. Once wool felts, it’s very hard to fix.

Packlove insight: This is why care labels for wool items often say hand wash only or dry clean only. This helps avoid the heat, moisture, and agitation that cause felting. These influences on fabric shrinkage are key to understanding how to care for your items. Knowing what causes cotton clothes to shrink or does hot water make clothes shrink more helps in choosing the right laundry settings.

2.2 Internal fabric stress: the role of manufacturing tension

Another reason fabrics shrink, especially new ones, is because of how they are made. When fabric is created – from spinning yarn, to weaving or knitting – it gets stretched. This happens again during the ‘fabric finishing process’. All this stretching and pulling creates hidden stress or ‘tension’ inside the fabric.

Think of it like a rubber band that’s been stretched out for a while. It wants to go back to its smaller, relaxed shape. When you wash the fabric for the first time, the water and warmth help these stretched fibers to finally relax.

As they relax, they go back to a more natural, and often smaller, size. This is called ‘relaxation’ shrinkage. This is why brand new clothes often shrink a little bit after their very first wash. This happens even if you follow the care label perfectly. It’s the fabric settling into its true size from the ‘manufacturing process’.

Packlove insight: We see this in textile manufacturing. Most fabrics have some level of tension from production. That’s why ‘pre-shrunk’ fabrics (which we’ll talk about later) are treated to release this tension before they are sold.

3. Factors influencing how much a fabric shrinks

Not all fabrics shrink the same way or by the same amount. Several factors play a role.

3.1 Fiber type: the biggest player

The primary factor determining how much a fabric will shrink is its fiber composition. This is the ‘fiber type’ or ‘material composition (fiber)‘.

- Natural fibers: These fibers usually shrink more than man-made ones. Examples include cotton (famous for shrinking, especially with hot water/dryer), wool (also shrinks easily, can felt), linen (tends to shrink), and rayon/viscose (can shrink a lot, needs gentle handling).

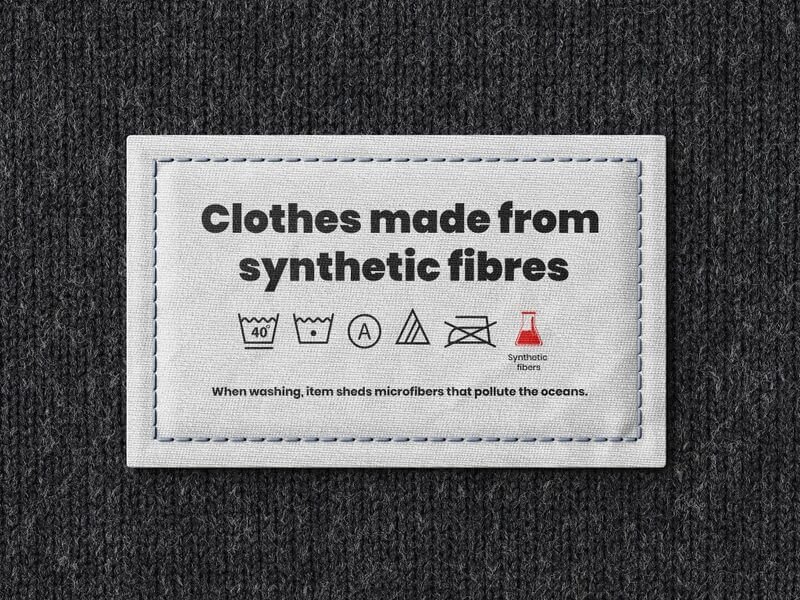

- Synthetic fibers: These fibers are generally much more stable and don’t shrink much, if at all. Examples include polyester, nylon, and acrylic, which usually shrink very little as they don’t soak up much water.

- Blends: Many fabrics are made from a mix of fibers. These blends often shrink less than 100% cotton but might shrink a bit more than 100% polyester, depending on the percentage of each fiber.

- Shrinkage percentages: Regular cotton might shrink around 3-5%, sometimes up to 10% or more if not treated. Wool can also shrink significantly. Polyester usually shrinks less than 1%. These are general examples of “shrinkage percentage of different fabrics”.

Packlove’s experience: When customers ask us about labels for different garments, the fiber type is one of the first things we discuss. A label that works great on polyester might behave differently on high-shrinkage cotton.

| Fiber category | Examples | Shrinkage tendency | Notes |

|---|---|---|---|

| Natural | Cotton, wool, linen, rayon | High | Absorb more water, sensitive to heat |

| Synthetic | Polyester, nylon, acrylic | Low | Resist water, more stable |

| Blends | Cotton/poly | Medium | Depends on fiber ratio |

3.2 Fabric structure: weave and knit

Besides the fiber type, how those fibers are made into fabric also plays a role. The two main ways are ‘weave’ and ‘knit’. These are important fabric properties.

- Weave (e.g., denim, shirting, bed linens): Woven fabrics are made by interlacing threads at right angles. Tightly woven fabrics might shrink a bit less than loosely woven ones.

- Knit (e.g., T-shirts, sweaters, leggings, socks): Knitted fabrics are made by creating connected loops of yarn. This structure can allow for more ‘relaxation’ shrinkage, as the loops can tighten and pull closer together. Knits can also sometimes change shape more easily when they shrink.

So, a cotton T-shirt (knit) might seem to shrink differently than cotton bedsheets (woven), even if they are both 100% cotton, because of their structure.

Packlove experience: We notice that the way a fabric is constructed affects how a label sits on it, especially after washing. For example, a stiff woven label might pucker more on a soft, stretchy knit if there’s differential shrinkage.

3.3 Fabric finishing processes

Sometimes, fabric makers treat fabrics at the factory to help them shrink less. This is part of the ‘fabric finishing process’.

- “Pre-shrunk” fabrics: You might see labels that say ‘pre-shrunk.’ this means the fabric was washed and shrunk on purpose by the manufacturer before it was cut and sewn into clothes or sold as fabric. A common treatment for cotton to make it ‘pre-shrunk’ is called ‘Sanforized (a process to pre-shrink cotton fabrics, reducing residual shrinkage to about 1%).’ garment manufacturers can apply pre-shrinking treatments.

- Other finishes: There are also other chemical finishes or heat treatments (‘shrink-resistant treatments’) that can make fabric more stable and less likely to shrink.

Knowing if a fabric is pre-shrunk helps you predict how it will behave after washing.

Packlove insight: For businesses creating garments, using pre-shrunk fabric is often a good investment in quality. It means the custom labels and patches we provide for them will continue to look good on the garment, wash after wash. This prevents puckering due to fabric shrinkage.

3.4 Garment construction

How clothes are actually cut and sewn together (garment construction) can also make a difference. It affects how shrinkage appears. For example, if the fabric pattern pieces are not cut correctly along the grain, shrinkage might make the garment twist or hang crookedly.

The seams might pucker or look uneven. This is more about the quality of how the garment is made, but it can interact with how shrinkage affects the final look and its dimensional stability.

4. How to prevent or minimize fabric shrinkage: practical tips

While some shrinkage is natural, you can take steps to reduce it.

4.1 Reading care labels: your first line of defense

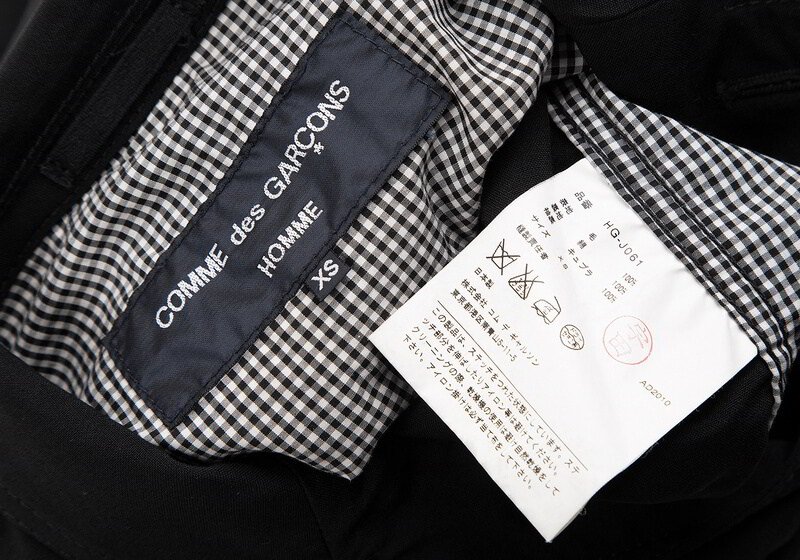

The very first and most important thing you can do to prevent shrinkage is to always read the garment care labels! These labels are like instruction manuals for your clothes. The care label provides shrinkage guidance. You usually find them sewn into a seam on the inside of your clothes. Learning “how to read clothing care labels” is key.

- Wash tub: This symbol tells you about washing. Look for dots or numbers inside it: one dot means cold water (around 30°c/86°f). Two dots mean warm (around 40°c/104°f). More dots mean hotter water. A hand in the tub means hand wash only.

- Square (drying): A square is for drying. A circle inside the square means you can use a tumble dryer. Dots inside the circle tell you the heat setting (one dot for low heat). Lines inside the square mean air dry. For example, a horizontal line means dry flat, and vertical lines mean hang to dry.

- Iron: The iron symbol tells you if you can iron the item. It also shows the temperature (dots again indicate low, medium, or high heat).

Following these instructions is your best defense against unwanted shrinkage. The people who made the garment know how to care for it best.

Packlove experience: We always advise looking at care labels. This is important not just for the garment itself, but also when considering adding custom elements. If a garment is ‘dry clean only,’ you wouldn’t want to add a label that can’t be dry cleaned.

4.2 Smart washing practices

Besides following the care label, here are some ‘best washing practices for clothes’ to help minimize shrinkage. The washing method affects the shrinkage outcome.

- Water temperature: Generally, cold water is your best friend for preventing shrinkage. Wash in cold (around 30°c/86°f or lower) whenever possible. Use warm water only if the label says it’s okay or if clothes are very dirty. Try to avoid hot water for fabrics prone to shrinking.

- Detergent: Use a mild detergent. Harsh detergents can be tough on fabric fibers.

- Wash cycle: Choose the gentle or delicate cycle on your ‘laundry machine settings.’ this means less spinning and ‘agitation’.

- Load size: Don’t cram too many clothes into the washing machine. Overloading can stress fibers.

Packlove experience: From our experience helping clients with textile products, simple changes in laundry habits can significantly extend the life and look of garments.

4.3 Drying techniques to reduce shrinkage

How you dry your clothes is just as important as how you wash them.

- Air drying (best option): Air drying is the gentlest way to dry your clothes. Lay sweaters and heavy knits flat. You can hang lighter items on a clothesline or drying rack.

- Machine drying (if you must): If you need to use a clothes dryer, always choose the lowest ‘dryer heat’ setting your clothes can handle. Take clothes out of the dryer while they are still slightly damp, then let them finish air drying. Over-drying clothes is one of the biggest culprits for shrinkage!

Packlove insight: We’ve seen that items dried carefully on low heat or air-dried tend to maintain their original dimensions much better. This is crucial for how any sewn or heat-applied labels continue to look over time.

4.4 For crafters and small businesses: the importance of pre-washing

This tip is especially for those who make things with fabric. Always ‘pre-wash’ your fabric. This means you wash and dry the new fabric before you cut it and sew it into your final product. If you pre-wash, your finished item won’t shrink or get misshapen the first time its new owner washes it. Wash and dry your new fabric using the same methods you expect the final item to be laundered with.

At Packlove, we often advise our clients who create textile products to pre-wash their materials. This ensures that the custom woven labels or other branding elements they order from us will be applied to a stable fabric.

This way, the label won’t pucker or cause distortion on the final product after its first wash. Making handmade items or your own clothing line? Ensure your branding looks great wash after wash. Explore Packlove’s durable woven labels perfect for pre-shrunk fabrics!

Fabric shrinkage can also affect your brand’s appearance. Choosing the right labels is important.

5.1 How fabric shrinkage can affect your brand’s image

Fabric shrinkage doesn’t just change how clothes fit. It can also mess with your brand’s image, especially how your labels and tags look. If your main garment fabric shrinks but your brand label doesn’t shrink at the same rate, you can get problems. This is key advice on how fabric shrinkage can affect branding elements like tags and patches.

The fabric around the label can get puckered and wrinkled. This makes it look messy and unprofessional. Alternatively, if a label shrinks more than the garment fabric, the label itself can look distorted or crinkled. It might even start to peel off or pull at the fabric.

This relates to the “impact of shrinkage on printed designs” and “how labels (like woven or heat transfer) react to fabric shrinkage.” either way, this makes the whole garment look like it’s lower quality. This can damage how people see your brand.

Packlove experience: We understand that every detail counts for branding. We’ve seen firsthand how a beautifully designed garment can be let down by a label that reacts badly to washing because of differential shrinkage. This is why choosing the right label material for your fabric is so important.

5.2 Smart label choices for fabrics prone to shrinkage

The key to avoiding these problems is to choose a label material that behaves similarly to your garment fabric, or one that is stable enough not to be affected. Packlove offers several options.

Woven labels

Our polyester woven labels are an excellent choice for many garments, especially those made from natural fibers like cotton that might shrink. Polyester itself shrinks very little, so these labels tend to stay flat and smooth. They are also very durable.

Packlove experience: We frequently recommend our polyester woven labels for cotton T-shirts, denim items, and children’s clothing.

Heat transfer labels (tagless tags):

For heat transfer labels, it’s very important to match the specific type of transfer to your fabric. Some of our heat transfers are designed with excellent flexibility and stretch, making them suitable for knit fabrics, activewear, or fabrics that might experience some movement or minor shrinkage. The Packlove team can advise you on the best heat transfer formulation for your specific fabric.

Rubber labels (PVC/silicone patches):

Rubber labels (often made from PVC or silicone) are inherently stable and do not shrink. They are a fantastic option for outerwear, bags, hats, or items where the fabric itself is also quite stable.

5.3 Ensuring your Packlove branding elements endure

At Packlove, we’re committed to helping your branding look fantastic and last as long as your products do. We know that details like how a label interacts with fabric shrinkage are important. Our team can help you choose the best labels, tags, or patches for your specific fabric type.

We use information on material compatibility between Packlove products and various textiles considering shrinkage to recommend the most compatible options. Not sure which material is best? Consider ordering our Value Booster Kit. It includes samples of different label materials.

Packlove experience: Our team has guided many brands in selecting branding elements that stand up to real-world use. We share our experience to help you avoid common pitfalls and make choices that enhance your brand. Got a specific fabric in mind? Talk to Packlove for expert branding advice on label compatibility. Want to see our materials firsthand? Order your Value Booster Kit and feel the quality.

6. Advanced insights into shrinkage

For those interested in more details, here are a few more concepts. This relates to general material behavior.

6.1 Different types of shrinkage

For those who like a bit more detail, shrinkage can be described in a few specific ways:

- Relaxation shrinkage: This is when fabric relaxes from the stress of being made. It usually happens during the first wash.

- Felting shrinkage: This happens mostly to wool. The fibers mat and lock together when exposed to heat, moisture, and movement.

- Hygral expansion (and contraction): This is when fibers swell up as they absorb water, and then shrink as they dry out.

- Differential shrinkage: This happens when different parts of a garment shrink at different rates, causing puckering or twisting.

6.2 Understanding shrinkage percentages and testing

You might hear shrinkage talked about in numbers:

- Shrinkage percentage: Shrinkage is often measured as a percentage. For example, if a fabric has 5% shrinkage, it means a piece that was 100cm long would become 95cm long after shrinking.

- Testing: Fabric manufacturers use special tests (‘textile testing standards’) to measure how much a fabric is likely to shrink.

7. Frequently asked questions (FAQ) about fabric shrinkage

Here are answers to some common questions about fabric shrinkage.

7.1 Can you reverse shrinkage once it has happened?

Sometimes you can unshrink clothes a little bit, especially knit fabrics like cotton, wool, or cashmere. Try soaking the item in lukewarm water with a bit of gentle hair conditioner or baby shampoo for about 30 minutes. Gently squeeze out the water (don’t wring!).

Lay it flat on a towel, and carefully stretch it back to its original shape while it’s damp. Let it air dry flat. However, this isn’t a guaranteed fix and works best for mild shrinkage. Severe shrinkage, especially felting in wool, is usually permanent.

7.2 Do all 100% cotton fabrics shrink the same amount?

No, not all 100% cotton fabrics shrink the same. The amount of shrinkage depends on the cotton type, how the fabric is made, and if it was ‘pre-shrunk’. Untreated cotton can shrink 5% or more. ‘pre-shrunk’ cotton might shrink only 1-3%.

7.3 How much shrinkage is considered “normal”?

There isn’t one “normal” amount. For good quality ‘pre-shrunk’ garments, 1-3% shrinkage after a few washes might be acceptable. For untreated natural fibers, 5% or higher can be typical. Synthetic fabrics like polyester usually shrink less than 1%.

7.4 Will dry cleaning prevent shrinkage?

Dry cleaning often helps prevent shrinkage for many fabrics because it uses solvents instead of water. This is why it’s recommended for delicate fabrics like silk, some wools, and rayon. However, it’s not a universal guarantee. Always follow the garment’s care label.

7.5 What does “pre-shrunk” really mean?

‘Pre-shrunk’ means the fabric manufacturer put the fabric through a controlled shrinking process before it’s sold or sewn into clothes. The goal is to get most potential shrinkage out upfront. It doesn’t mean zero shrinkage, but significantly reduces it.

Explore more:

So, while fabric shrinkage is a common thing, it doesn’t have to be a big problem! Understanding what causes it – like heat, moisture, and the type of fiber – is the first step. By knowing about different fibers, reading care labels, and using smart washing and drying habits, you can keep your clothes and fabric items looking their best for longer.

For designers and businesses, choosing the right fabrics and compatible branding elements means creating products that last. Quality labels from Packlove help keep customers happy. We hope this guide has helped you understand shrinkage better.

Remember, if you have questions about branding your textile products, Packlove is here to help! Still have questions about shrinkage or branding your items? Contact the Packlove team today for friendly advice! Ready to explore high-quality branding solutions? See Packlove’s custom labels, tags, and packaging.