Custom Woven Labels for Clothing: Design, Types and Ordering Guide

For clothing brands and handmade creators, strong branding is crucial. Are you looking to elevate your apparel, establish a professional image, and stand out from the competition? Perhaps you’re unsure about the best labeling solutions for durability and brand representation. Low-quality labels detract from even the finest garments, while generic branding hinders customer recognition and sales.

This guide to custom woven labels is your answer. Discover different label types and their applications. Learn to design eye-catching, brand-consistent labels. We’ll cover materials, folding, and attachment, plus manufacturing insights. Avoid common mistakes and gain the knowledge to choose the perfect woven label – one that adds luxury, ensures durability, and reinforces your brand identity. Elevate your apparel and make a lasting impression with the right custom woven labels.

1. Why choose custom woven labels for your clothing brand?

1.1 Elevating brand perception and perceived value

Custom woven labels add an undeniable touch of luxury and sophistication to any garment. Unlike basic printed labels, woven labels, with their textured feel and detailed design, instantly elevate the perceived value of your clothing. They communicate a sense of quality and attention to detail, signaling to customers that your brand prioritizes high-end craftsmanship. A well-designed woven label reinforces your brand image and creates a premium first impression.

For choosing suitable labels, consider your target audience. A high-end fashion brand targeting a discerning customer would benefit greatly from the luxurious feel of a Damask woven label, while a brand focused on casual wear might opt for a more durable, simpler woven option.

1.2 Durability and longevity: A long-term investment

Woven labels are renowned for their exceptional durability and longevity. Unlike printed labels that can fade or peel over time, woven labels are created by weaving threads together, resulting in a design that’s inherently wash-resistant, fade-resistant, and fray-resistant. This resilience makes them a sound, long-term branding investment, ensuring your brand remains visible and identifiable throughout the garment’s lifecycle.

Think about the lifecycle of the garment. A durable woven label ensures that your brand remains prominently displayed, even after numerous washes and wears, reinforcing brand recognition and communicating a commitment to quality.

1.3 Differentiation in a competitive market

In today’s crowded apparel market, differentiation is key. Custom woven labels provide a powerful way to stand out from competitors. By creating unique branding elements, showcasing your logo prominently, and incorporating custom designs, you establish strong brand recognition and create a memorable impression on your customers.

Remember, a woven label, though a small detail, can make a significant difference in how your brand is perceived. It’s a tangible representation of your brand identity and commitment to quality.

1.4 Showcasing your brand’s story and values

Woven labels offer an opportunity to go beyond basic branding and communicate your brand’s story and values. While your logo is central, you can also incorporate a short tagline, information about your brand’s origin, or highlight ethical sourcing or sustainable practices. This subtle messaging reinforces your brand identity and resonates with customers who value these aspects.

A strategically used tagline on your label can communicate your commitment to core values. For instance, “Crafted with Care” or “Sustainably Made” adds depth and connects with consumers who share those priorities.

2. Types of custom woven labels: Finding the perfect fit

2.1 Damask woven labels: High-definition detail and versatility

Damask woven labels are the industry standard for high-quality apparel. Their tight Damask weave creates a high-definition, incredibly detailed label, perfect for intricate logos and fine text. They offer a soft texture and a smooth finish, adding a professional, luxurious touch to high-end apparel, outerwear, and accessories. Damask’s versatility makes it suitable for a wide range of applications.

Remember, Damask is an excellent choice if your logo has fine lines or intricate details. The high-density weave ensures crisp reproduction, capturing every nuance of your design.

2.2 Satin woven labels: Luxurious shine and smoothness

Satin woven labels are known for their smooth, shiny surface and luxurious feel. The satin weave creates a lustrous finish that adds a touch of elegance and sophistication. These labels are often chosen for delicate garments like lingerie, sleepwear, or high-end fashion items where a soft, gentle touch is desired.

Satin labels add a touch of elegance and refinement, perfectly complementing garments that prioritize a luxurious feel and delicate aesthetic.

2.3 Taffeta woven labels: Economical and durable (but less detailed)

Taffeta woven labels offer a more economical and durable option, though with less detail compared to Damask. The Taffeta weave, a simpler plain weave, produces a sturdy label that’s cost-effective and suitable for basic apparel, workwear, or situations where budget is a primary concern. While Taffeta can’t achieve the same fine detail as Damask, it provides a reliable and practical labeling solution.

Taffeta is a good option if you’re ordering labels in large quantities and need a budget-friendly solution without sacrificing durability.

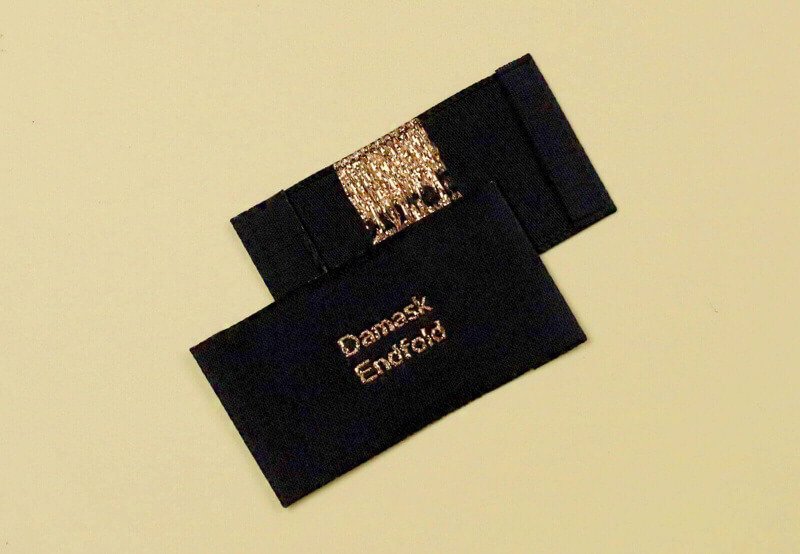

2.4 Understanding label folds: Center fold, end fold, and more

The way your woven label is folded significantly impacts its application and final appearance. Common fold types include:

- Center fold (loop label): Folded in the middle, creating a loop. Ideal for sewing into seams, providing space for branding on both sides.

- End fold: Folded on both ends, allowing the label to be sewn flat onto the garment.

- Manhattan fold: Similar to an end fold, but with an additional fold on one side to create a flap. This provides a cleaner, more finished edge.

- Miter fold: The ends are folded at a 45-degree angle, creating a pointed or triangular shape. Often used for decorative labels.

- Straight cut (no fold): These labels have no folds and are typically heat-sealed or adhesive-backed.

The fold you choose will depend on where you plan to attach the label and the desired aesthetic. Center folds are commonly used on necklines and waistbands, while end folds are often seen on hems and side seams.

3. Designing your custom woven labels: Best practices and tips

3.1 Keeping it simple: The key to effective label design

Simplicity is paramount in effective label design. Aim for a clean, uncluttered design that’s easy to read and instantly recognizable. Avoid overwhelming the label with too many colors, intricate details, or multiple fonts. A minimalist approach often yields the most impactful results.

Remember, clarity and readability should be prioritized above all else. A cluttered label is difficult to decipher and diminishes the professional image you want to convey.

3.2 Choosing the right colors and contrast

Color contrast is essential for ensuring your label is easily readable. Choose colors that stand out clearly against the label’s background. A limited color palette is generally recommended, as too many colors can create visual clutter and make the label look busy.

It’s a good idea to print a sample to test your color combinations before committing to a large order, ensuring the colors appear as intended on the woven material.

3.3 Selecting the perfect font: Readability is paramount

Font choice plays a critical role in label readability. Opt for clear, legible fonts, with sans-serif fonts often being the best choice for their clean lines and simplicity. Avoid using very thin fonts or overly decorative fonts that can be difficult to read, especially at smaller sizes.

Avoid fonts with very fine lines, as they may not weave clearly on the label, compromising legibility. Choose a font size and weight that ensure all text is easily readable.

3.4 Label size and placement: Strategic considerations

The size and placement of your woven label should be carefully considered in relation to the garment. The label should be appropriately sized for the garment and its location, neither too large nor too small. Common placement options include the neckline, side seam, or hem.

Consider the overall design of the garment when determining label size and placement. The label should complement the garment’s aesthetics, not detract from them. Strategic placement also maximizes brand visibility.

3.5 Including essential information: Beyond the logo

While your brand name and logo are central, woven labels should also include other essential information. This typically includes country of origin, care instructions, fabric content, and size. Depending on your location and the type of garment, there may be specific legal requirements for labeling, including fiber content and RN numbers.

It’s crucial to ensure that you comply with all applicable labeling regulations for your target market. Providing clear and accurate information on your labels builds trust with consumers and protects your brand from potential legal issues.

4. Manufacturing and ordering your custom woven labels

4.1 Understanding the weaving process

Woven labels are created on a loom, a specialized machine that interweaves threads to form the fabric and design. The process involves warp threads (running lengthwise) and weft threads (running crosswise). These interlocking threads, guided by the loom’s mechanism, create the label’s texture and the intricate details of your design.

Understanding the basics of the weaving process can help inform your design choices. For instance, knowing that very fine details might be challenging to replicate perfectly can guide you towards simpler, bolder designs for optimal results.

4.2 Choosing the right label material: Polyester, cotton, and recycled options

The most common materials for woven labels are polyester, cotton, and recycled yarn. Polyester is highly durable, resistant to fading and shrinking, and offers excellent color retention. Cotton provides a softer, more natural feel, making it ideal for brands emphasizing organic or eco-friendly values. Recycled yarn options are increasingly available, offering a sustainable choice that aligns with environmentally conscious branding.

Consider your brand values and the desired aesthetic when choosing a material. Polyester offers durability and versatility, cotton provides a natural touch, and recycled options demonstrate a commitment to sustainability.

4.3 Minimum order quantities (MOQs) and pricing

Minimum order quantities (MOQs) vary significantly between label suppliers. Some suppliers may have MOQs as low as a few hundred labels, while others may require orders of thousands. Pricing is influenced by several factors, including the label size, design complexity, material cost, and, crucially, the order quantity. Larger orders typically result in lower cost per label due to economies of scale.

It’s always best practice to get quotes from multiple suppliers to compare pricing and MOQs, ensuring you find the best value for your needs.

4.4 Turnaround time and shipping

Turnaround time, the time from order placement to label delivery, varies depending on the supplier, the complexity of the design, and the order quantity. A typical range might be anywhere from 1 to 4 weeks, but this can vary. Shipping options and costs also vary, with standard and expedited options generally available.

Factor in turnaround time when planning your product launches or restocking needs. Discuss production and delivery timelines with your supplier upfront to ensure your labels arrive when you need them.

4.5 Working with a reliable label supplier

Choosing a reliable label supplier is paramount. Look for suppliers with proven experience, a strong portfolio demonstrating quality workmanship, excellent customer service, and clear communication. Requesting samples before placing a large order is always recommended. Obtain detailed quotes outlining all costs, including setup fees, material costs, and shipping charges.

Don’t hesitate to check the supplier’s reputation by asking clarifying questions and, if possible, seeking testimonials or reviews from other customers. A strong partnership with a reputable supplier ensures a smooth ordering process and high-quality labels.

5. FAQs about custom woven labels for clothing

5.1 What is the difference between woven and printed labels?

The key difference lies in their construction. Woven labels are created by weaving threads together on a loom, resulting in a textured, durable label where the design is integral to the fabric. Printed labels, on the other hand, are made by printing ink onto a pre-existing fabric, making them generally less durable and prone to fading or peeling over time.

5.2 Can I get a sample of my woven label before placing a bulk order?

Yes, most reputable label suppliers offer sample production. This allows you to physically check the label’s quality, colors, and design details before committing to a large order. It’s a crucial step to ensure the final product meets your expectations.

5.3 What file format should I provide for my label design?

Vector files (such as AI, EPS, or PDF) are the preferred format for label designs. Unlike raster images (like JPG or PNG), vector files are scalable without losing quality, ensuring your design is reproduced sharply and accurately on the woven label, regardless of size.

5.4 How do I ensure my woven labels are compliant with labeling regulations?

To ensure compliance, thoroughly research the labeling regulations specific to your target market (country or region). These regulations typically cover requirements for fiber content, country of origin, care instructions, and potentially other information. Include all required details on your label design.

5.5 What are the most eco-friendly options for woven labels?

For environmentally conscious brands, recycled yarn (often made from recycled polyester) and organic cotton are excellent eco-friendly choices for woven labels. These materials minimize environmental impact compared to conventional polyester or conventionally grown cotton.

6. Packlove – Providing service for custom woven labels

With over 8 years of experience in the garment industry, particularly in processing labels and tags for clothing, Packlove is your trusted partner for high-quality, custom woven labels. We are dedicated to providing personalized solutions that meet your brand’s unique needs and elevate your apparel.

Our expertise extends from design consultation to material selection and production, ensuring your labels perfectly reflect your brand identity and enhance your garments. We’re committed to delivering exceptional quality and service, helping you create labels that make a lasting impression.

Contact Packlove today for expert advice or to place your order. Visit Packlove to explore our services and get started on creating the perfect woven labels for your brand.

Read more:

Custom woven labels are a powerful branding tool, offering durability, design versatility, and a touch of luxury that elevates any garment. From selecting the right weave and material to designing an effective label and navigating the manufacturing process, this guide has equipped you with the knowledge to make informed decisions. Remember, a well-crafted woven label is more than just a tag; it’s a statement of quality, a reflection of your brand’s identity, and a lasting impression on your customers. Invest in high-quality woven labels to enhance your apparel and create a brand that stands out. Start designing your perfect woven labels today!