Embossing: Add Texture And Value to Apparel Branding

For small apparel businesses striving to make a mark, standing out and conveying quality can be significant hurdles. Your branding materials – including essential items like hang tags, labels, and packaging – serve as critical touchpoints with your customers. However, standard flat printing can sometimes feel generic, failing to capture the unique essence of your apparel brand.

Embossing offers a compelling solution, providing a way to add a distinct, premium feel and tactile dimension that elevates the perceived value of your products. This guide explores the world of embossing: what the process entails, the different styles available, the tangible benefits for clothing brands, and practical tips for implementation. You will gain insights into how this technique can effectively differentiate your brand through enhanced texture and visual appeal.

1. More than just a raised surface

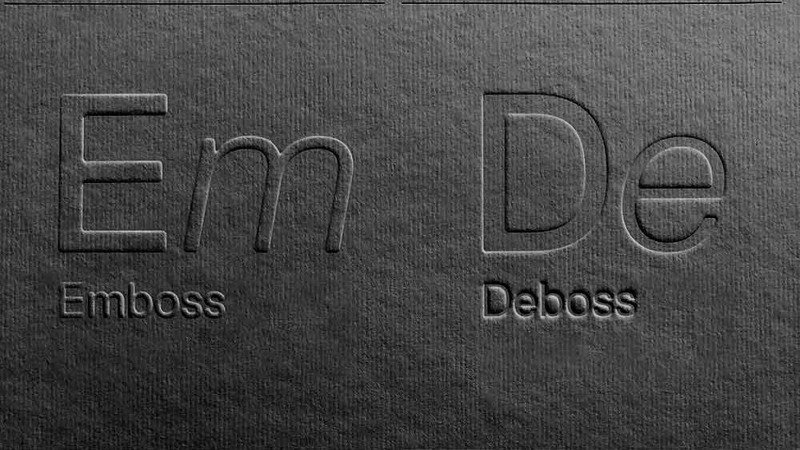

Embossing is a finishing process that creates a raised design on a material like paper or cardstock. Imagine pushing the design up from the surface. Conversely, debossing achieves the opposite effect, creating a recessed image or sunken impression into the material, much like pressing a design down. Both techniques utilize metal plates called dies (a matched pair for pressing the material), but they produce distinct visual and tactile texture outcomes. Embossing results in a design that stands proud of the surface, while debossing creates an indent.

1.2 How pressure creates an embossed effect?

The creation of an embossed effect relies on precise pressure application using a specialized embossing die set. This set consists of two metal plates: a male die, which has the desired image raised on its surface, and a female die, featuring a corresponding recessed version of the image.

The chosen material, typically a paper substrate like cardstock for hang tags, is positioned between these two dies. A press machine then applies significant pressure, forcing the material into the contours of the female die via the male die. This action permanently reshapes the paper fibers, resulting in the raised design characteristic of embossing.

2. Choosing the right look for your brand

2.1 Blind embossing

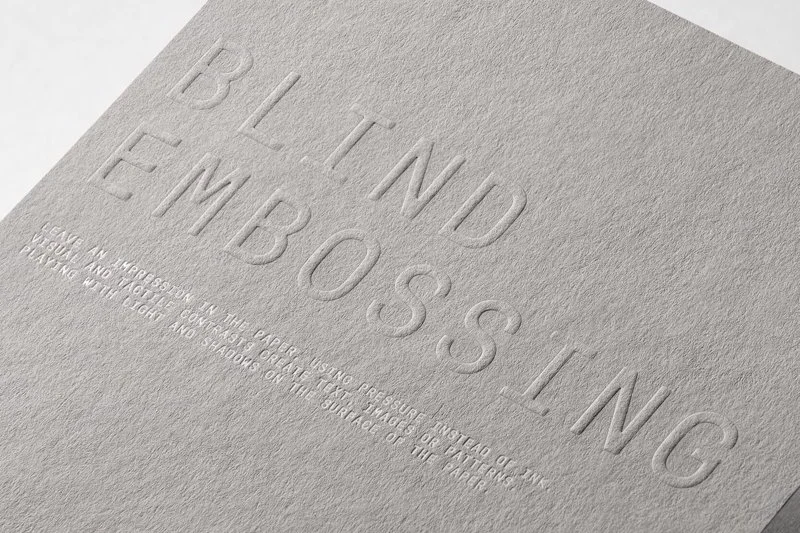

A blind emboss effect refers to the creation of raised imagery without the use of any ink or foil. The design is formed solely through the physical alteration of the paper surface. This technique yields a subtle impression, offering a clean, sophisticated, and often minimalist aesthetic.

The appeal lies entirely in the interplay of light, shadow, and texture. Blind embossing is ideally suited for applying logos or background patterns where understated elegance is desired, adding dimension without introducing color.

2.2 Registered embossing

Registered embossing involves carefully aligning the embossed (raised) area with another design element that has already been applied, such as print (ink) or foil stamping. This requires precise alignment, often referred to as registration (hence the name color register embossing when aligned with ink).

The result adds visual complexity and depth, allowing specific parts of a printed logo or a foiled shape to gain a raised dimension, enhancing their prominence. For example, just the lettering of a brand name might be embossed after being printed, or a foiled border could be embossed.

2.3 Combination embossing (foil emboss)

Often simply called foil emboss, combination stamping merges foil stamping directly with embossing. During this process, a metallic foil sheet (or pigmented foil) is applied precisely onto the raised, embossed area. This can happen simultaneously with a specialized die or in two perfectly aligned steps.

The outcome is highly impactful, marrying the texture and shine of foil with the dimensional quality of embossing for a striking 3D effect. Common foil choices include gold, silver, copper, various colors, holographic patterns, and even matte finishes, offering a luxurious look and feel.

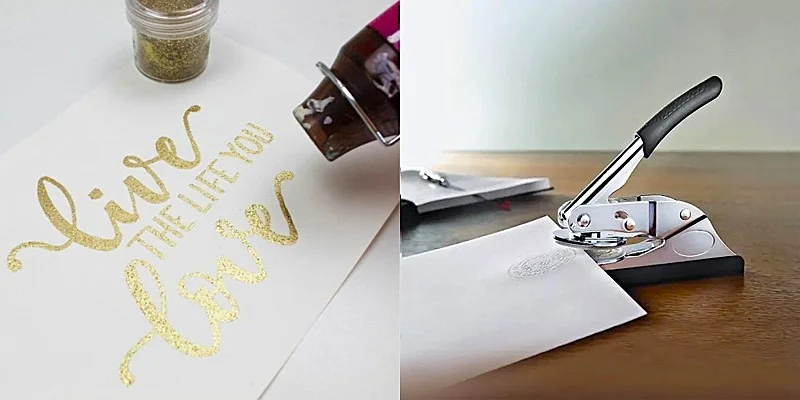

2.4 Heat vs. dry embossing

Some confusion can arise from terms used in the crafting world. “Heat embossing” in crafts typically involves heat embossing powder sprinkled over wet ink and melted with a heat tool (like a specialized heat gun) to create a raised, often glossy effect. “Dry embossing” in crafts often refers to using an embossing folder (a plastic folder with a pattern) and a stylus or machine to press a design into paper.

For commercial embossing used in producing professional apparel tags and packaging, the primary method relies on pressure applied through metal dies, as described earlier. While heat can be incorporated commercially, especially during foil application or for specific effects like glazing (creating a shine) or scorching (creating a burnished look), the fundamental process for creating the raised dimension on tags is pressure-based die stamping. What crafters call “dry embossing” is conceptually similar to commercial blind embossing (pressure without ink/foil). The key takeaway for branding materials is the reliance on precision dies and pressure machines.

3. Why invest in embossing?

3.1 Elevating perceived value

The addition of texture and visual depth through embossing immediately communicates a higher quality and greater attention to detail. This tactile element enhances the perceived value of the product in the customer’s mind.

An embossed tag or package simply feels more substantial and carefully produced, which signals craftsmanship. This enhanced perception can support a premium brand image, contribute to a luxury appeal, and help justify price points.

3.2 Creating memorable touchpoints

Branding effectiveness increases when multiple senses are engaged. Tactile branding leverages the sense of touch. An embossed surface is inherently more engaging than a flat one; the simple act of touching the raised design creates a more memorable touchpoint for the customer.

This positive sensory experience fosters a stronger connection with the brand, associating the tactile quality with the overall product experience. Enhanced customer engagement often starts with these small, tangible details.

3.3 Enhancing brand recognition

Embossing naturally draws the eye towards the raised element. By applying this technique to your logo or brand name on tags and packaging, you create strong logo emphasis. The physical dimension makes these key identifiers physically stand out from the surrounding surface. This improves the visual hierarchy of your branding elements, making your logo more prominent and potentially increasing brand recall.

3.4 Competitive differentiation

In a crowded market saturated with apparel brands, finding ways to differentiate is crucial. Embossing offers a tangible method for competitive differentiation. Many competitors may rely on standard flat printing for their tags and packaging.

Investing in embossing provides uniqueness that can capture customer attention, whether on the retail floor or during the unboxing experience at home. View embossing not just as a finish, but as a strategic choice to elevate your brand presentation.

4. Bringing embossing to life

Premium hang tags often represent the customer’s first detailed physical interaction with your brand identity off the garment. Using embossing here makes a powerful first impression. Consider applying the technique to:

- Your primary logo or wordmark.

- A secondary brand monogram or icon.

- Key graphic elements unique to your collection.

- Subtle background patterns for overall texture.

Using a heavier cardstock material (e.g., 350gsm or higher) enhances the depth and feel of the emboss. Combining embossing with custom die-cut shapes can further elevate the tag’s uniqueness.

While traditional fabric apparel labels like woven labels or satin printed tags are not typically embossed using pressure dies, related branding elements can benefit. Faux leather or PU leather patches, often sewn onto outerwear, jeans, or bags, are frequently embossed or debossed to feature logos or brand names. This application is highly relevant for external apparel trim production where a durable, textured branding element is desired. Standard care labels generally remain flat printed for legibility.

4.3 Sophisticated packaging

Extend the tactile experience beyond the garment itself. Embossing lends itself beautifully to sophisticated packaging. Consider applying your logo or a brand pattern to:

- Product packaging box designs, such as rigid setup boxes or folding cartons.

- Custom mailer boxes used for shipping e-commerce orders.

- Paper belly bands wrapped around bundled items.

- Even custom tissue paper (requires careful selection of paper thickness and consultation with the producer).

A consistent embossed element across packaging components contributes significantly to a premium unboxing experience and reinforces cohesive branding.

4.4 Cohesive branding

For truly cohesive branding, extend the embossed aesthetic to other customer-facing materials. Embossed business cards immediately convey quality and attention to detail. Using the same technique on letterhead stationery, compliment slips, or even presentation folders reinforces your premium positioning across all touchpoints, ensuring brand consistency.

5. Planning your embossing project

5.1 Material matters

The choice of material significantly impacts the final result. Generally, heavier paper stock weight provides better embossability. Cardstock paper of 300gsm (grams per square meter) or higher allows for deeper, more defined impressions without easily tearing or showing excessive “bruising” (the debossed mark) on the reverse side.

Very thin stocks might not hold the impression well, while heavily textured papers can sometimes obscure fine details in the emboss. If using recycled paper aligns with your brand values, confirm its suitability for embossing with your print provider, as composition affects performance. Careful material choice is key.

5.2 Design details

Consider the design complexity. Extremely fine detail, such as very thin lines or tiny isolated elements, can be challenging to reproduce cleanly, particularly on textured stocks or with deeper embossing. The complexity also influences die requirements.

A simple, single-level die (raising the design to one uniform height) is typically made from magnesium or copper and is less costly. Achieving varying heights, rounded edges, or intricate textures requires a multi-level die or a sculpted die, usually crafted from more durable and expensive brass die material. Always consult your printer or packaging producer early in the design phase to discuss feasibility.

Be prepared for embossing to increase the production budget compared to standard printing. The main factors influencing embossing cost include:

- Die creation cost: This is usually a one-time expense per design, varying based on the die’s size, complexity, and material (magnesium vs. brass).

- Setup time: Each production run requires machine setup, adding to the cost, especially for smaller quantities.

- Run length: The cost per piece decreases as the quantity increases due to economies of scale.

Registered embossing or combination/foil embossing generally costs more than blind embossing due to the need for precise alignment, potential additional machine passes, and foil material costs.

6. Related questions

6.1 Can embossing be applied to recycled paper stock?

Yes, embossing is often possible on recycled paper, but success depends heavily on the specific stock’s thickness, fiber composition, and quality. Heavier weight recycled stocks tend to perform better. Consulting with your print provider and possibly testing the specific paper is advisable.

6.2 What’s the typical difference in cost between blind embossing and foil embossing?

Foil embossing (combination stamping) is generally more expensive than blind embossing. This increased cost stems from the price of the foil material itself, potentially more complex die requirements, and the added setup precision needed for aligning the foil with the embossed area. The exact cost difference varies based on design complexity, run size, and provider pricing.

6.3 How fine or detailed can an embossed logo or design realistically be on a hang tag?

The level of achievable design detail depends on the hang tag material, die quality, and the press capabilities. Very fine lines (e.g., less than 0.5 points wide) or tiny, freestanding elements can lose definition or even cause the paper to tear. It is generally best to avoid overly intricate designs for embossing or to consult closely with your producer, providing your artwork for assessment.

6.4 Does embossing affect the back side of the paper or card?

Yes, the pressure used in embossing creates a corresponding debossed impression, often called “bruising,” on the reverse side of the material. The visibility of this impression depends on the paper thickness and the depth of the emboss. This is an important consideration for double-sided design projects, as the debossed area on the back needs to be accounted for in the layout.

Read more:

- Custom Hang Tag Design: Create Unique Tags for Your Brand

- Clothing Brand Requirements: Labels, Packaging & Essentials

- What is a Brand Label? Build Identity & Customer Trust

Embossing stands out as a valuable finishing technique for enhancing apparel brand identity. By adding tactile appeal and visual depth to tags, labels, and packaging, this method effectively boosts perceived quality and provides tangible differentiation in a competitive landscape. The benefits – a premium feel, enhanced memorability, and a design that physically stands out – can significantly strengthen your brand presentation. Evaluate whether this sophisticated touch aligns with your specific brand positioning and the expectations of your target customers. Adding embossed elements demonstrates care and attention to detail that resonates with consumers seeking quality. Consider if the unique touch of embossing fits your brand story. For personalized expert advice on bringing these ideas to life for your tags and packaging, feel free to reach out to us at Packlove.