Fabric Composition: Quality, Cost And Customer Satisfaction

Ever wondered what is fabric composition and why it matters beyond just how a fabric feels? For apparel businesses, understanding this fundamental “recipe” of fibers is absolutely crucial. This guide explains exactly how composition directly impacts garment quality, production costs, perceived value, and ultimately, customer satisfaction and brand reputation.

You will learn to decode natural, synthetic, and blended fibers, understand their properties, and master reading fabric labels for smart sourcing and compliance. Gain the knowledge to choose the right materials for your specific garments and target market, making informed decisions that elevate your product line.

1. What exactly is fabric composition and why should your business care?

1.1 Defining fabric composition

Fabric composition details the exact textile materials used to create a fabric. Think of it like a recipe for fabric: it specifies the types of fibers and their percentage by weight. For example, a common label might read “60% cotton, 40% polyester.”

This precise material makeup isn’t just about naming ingredients; it’s a fundamental technical specification. Understanding this fiber content is the first step in understanding a fabric’s potential characteristics and suitability for different garments.

1.2 The bottom line impact

The choice of fabric composition directly influences several critical business implications. The fibers selected significantly impact the perceived quality of a garment – a rough, low-grade polyester will feel considerably different and less valuable than soft, high-quality cotton, affecting perceived value.

Different textile materials also come with varying cost points for sourcing and manufacturing, impacting overall profitability. Ultimately, these factors culminate in customer satisfaction. A fabric that feels good, performs well, and lasts appropriately builds brand reputation through positive reviews and repeat business, while poor choices can lead to returns and negative feedback.

1.3 First impressions matter

How a garment initially engages the senses often depends heavily on its fabric composition. The specific fibers and how they are constructed determine the texture or handfeel – whether a fabric feels soft, stiff, smooth, or rough against the skin. Composition also dictates the fabric’s drape, which is how gracefully (or rigidly) the material hangs and falls.

Consider the fluid drape of a silk-like viscose versus the structured form of a heavy cotton canvas. Visual aspects like sheen (a subtle shine) or a matte (non-shiny) finish are also tied to the material makeup, influencing the overall visual appeal and initial attraction of a garment made from specific textiles or blends.

1.4 Beyond the sale

Fabric composition is crucial for a garment’s functional performance attributes and longevity. Different fibers offer distinct properties: cotton provides excellent breathability, while polyester excels in durability and wrinkle resistance. Synthetics like polyester or nylon often provide good moisture-wicking capabilities, ideal for activewear. The presence of elastane (spandex) introduces stretch for comfort and fit.

These characteristics determine the garment’s suitability for its intended use and influence its overall wearability and lifespan. Proper garment care, often dictated by the fiber content, is also essential to maintain these properties and ensure the garment lasts as expected, avoiding issues like excessive pilling or loss of shape. Factors like insulation (for warmth) are also directly linked to the chosen textile materials.

2. Decoding the fibers

2.1 Natural fibers

Natural fibers originate directly from plant fibers or animal fibers. These materials are often valued for characteristics such as breathability and, in many cases, biodegradability, returning to the earth more readily than their synthetic counterparts.

- Cotton (CO): A versatile staple, cotton (CO) is derived from the cotton plant and is prized for its soft feel, excellent breathability, and high absorbency. These qualities make it a go-to natural fiber for everyday items like t-shirts, denim, and underwear. Its pros include comfort against the skin and good dye acceptance; it can also be hypoallergenic for sensitive skin. However, cotton is prone to wrinkling and shrinkage if not properly finished or cared for, and it dries relatively slowly. Cost factors for cotton can vary significantly based on quality and origin (e.g., organic, Pima).

- Linen (LI): A breathable but wrinkle-prone fiber made from the flax plant, linen (LI) is strong and known for being highly breathable and having a distinctive crisp, textured feel. Ideal for warm-weather clothing like shirts and trousers, its major pro is the cool sensation it provides. However, linen wrinkles easily and persistently, which is part of its aesthetic but requires management. Its production process can also make it more expensive, giving it a niche appeal.

- Wool (WO): Known for warmth and resilience, wool (WO) is sourced primarily from sheep and is the quintessential natural fiber for warmth due to its excellent insulating properties. It’s also naturally moisture-wicking (drawing moisture away from the skin), elastic, and somewhat wrinkle-resistant. Common in sweaters, suits, and outerwear, its pros are warmth and durability. Cons can include potential itchiness (though finer wools like Merino mitigate this), complex care requirements (care instructions often specify hand washing or dry cleaning), and higher cost.

- Silk (SE): A luxury fiber with caveats, silk (SE) is produced by silkworms and is synonymous with luxury. Its defining properties are its natural luster, smooth handfeel, surprising strength for its weight, and elegant drape. Silk is frequently used for high-end blouses, dresses, scarves, and linings. The obvious pro is its luxurious look and feel. However, it comes with significant cons: it’s expensive, delicate, prone to water spotting, and typically requires dry cleaning, making it less practical for everyday wear and demanding careful handling.

2.2 Synthetic fibers

Synthetic fibers are man-made fibers produced through a chemical process, often using petroleum-based ingredients. They are engineered to offer specific properties not always found in natural fibers, such as exceptional durability, wrinkle resistance, or stretch, often at a lower cost point.

- Polyester (PL): The workhorse fiber, polyester, is arguably the most common synthetic fiber. Extremely durable, wrinkle-resistant, abrasion-resistant, quick-drying, and excellent at retaining its shape, it’s used extensively in activewear, outerwear, and everyday clothing, often blended with other fibers. Its major advantages are versatility, ease of care, and being highly cost-effective. The downsides include being significantly less breathable than most natural fibers, sometimes having a less natural feel, potential for pilling, and growing environmental concerns regarding its production and end-of-life. Blending polyester with natural fibers like cotton helps balance these properties.

- Nylon (PA): Known for strength and elasticity, nylon is another widely used synthetic fiber, known for being exceptionally strong, abrasion-resistant, lightweight, and elastic. These characteristics make it ideal for applications requiring durability and stretch, such as hosiery, swimwear, parachutes, activewear components, and reinforcing fibers in blends. Its primary pros are strength and elasticity. Cons include relatively low breathability compared to natural fibers and sensitivity to high heat.

- Spandex/Elastane (EL): The stretch factor. Known interchangeably as spandex or elastane, this synthetic fiber’s defining characteristic is its incredible stretch and recovery (elasticity), allowing fabrics to stretch significantly and return to their original shape. It’s almost exclusively used in blends – even 2-5% can drastically improve fit and comfort in garments like activewear, jeans, swimwear, and fitted tops. The main pro is the comfort and freedom of movement it adds. Cons include sensitivity to high heat and potential degradation over time with exposure to chlorine or oils.

- Rayon/Viscose (VI): The semi-synthetic option. Rayon, often referred to as viscose, occupies a unique space as a semi-synthetic, cellulose-based fiber. It’s made from natural cellulose but requires significant chemical processing. Rayon/viscose mimics some natural fiber properties: it’s generally soft, absorbent, offers good drape, and is quite breathable, similar to cotton. Common uses include dresses, blouses, and linings, often serving as a more affordable alternative to silk. Pros are its comfort and relatively low cost. However, it weakens considerably when wet, wrinkles easily, and requires careful washing, making it less durable in some respects than the natural fibers it resembles. While derived from natural sources, its processing places it commonly alongside other synthetic fibers in classifications.

2.3 The power of blends

A fabric blend involves combining two or more different fiber types during manufacturing. The goal is to leverage the strengths of each fiber and mitigate their weaknesses, achieving specific combined properties. This strategy allows for performance enhancement and effective cost management.

Common apparel blends explained: Many successful garments rely on blended fabrics. Some frequent examples include:

- Cotton/poly blend (TC) (e.g., 60% cotton/40% polyester, 50/50): This blend is very common for t-shirts, hoodies, and sweatshirts. It balances cotton’s comfort and breathability with polyester’s durability, wrinkle resistance, and faster drying time.

- Poly/spandex (e.g., 95% polyester/5% spandex): This is the standard for much activewear, providing polyester’s durability and moisture management with spandex’s essential stretch for movement and fit.

- Wool blends (e.g., wool/nylon): Adding nylon to wool increases durability and abrasion resistance, particularly useful for socks or heavier outerwear, without sacrificing too much warmth.

- Tri-blends (e.g., polyester/cotton/rayon): These blends aim for a premium feel, combining polyester’s structure, cotton’s comfort, and rayon’s softness and drape, often resulting in exceptionally soft t-shirts.

Benefits of blending for your business: Utilizing blends offers several strategic advantages for an apparel business:

- Improved durability: Adding stronger synthetic fibers can extend garment life.

- Reduced wrinkling: Polyester content significantly cuts down on ironing needs compared to 100% cotton or linen.

- Enhanced feel: Blending can soften coarser fibers or add a desired texture.

- Stretch addition: Incorporating spandex provides necessary comfort and fit.

- Price point control: Blending can help achieve desired fabric qualities at a more accessible cost.

- Easier care: Blends often simplify washing instructions for the end consumer.

3. Reading the fine print

3.1 Why label accuracy is non-negotiable

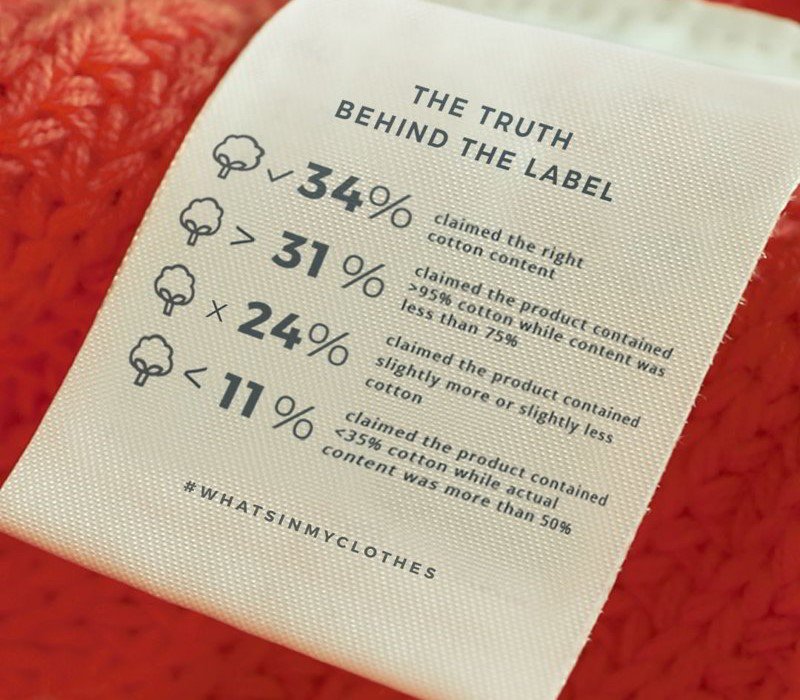

Accurate fabric labeling isn’t just good practice; it’s essential for several reasons. Firstly, there are strict legal requirements, particularly for import/export activities. Markets like the US and EU have specific textile labeling rules (FTC regulations in the US) that must be followed to avoid customs delays, fines, or seizure of goods. Secondly, transparency about what a garment is made of builds customer trust and enhances your brand’s trustworthiness.

When customers know what they are buying, they can make informed decisions. Thirdly, correct labeling ensures appropriate garment care, leading to longer product life and greater customer satisfaction. Finally, accurate labels serve as a crucial baseline for quality control, helping ensure consistency between what was ordered and what was received from suppliers. Inaccuracy can lead to significant business risks.

3.2 How to read a fabric content label

Understanding a fabric label or fiber content label is straightforward once you know the standard format. Regulations typically require listing fibers that constitute 5% or more of the total weight. These fibers must be listed by their generic fiber names in descending order of fiber percentage by weight.

For instance, a label stating “60% cotton, 40% polyester” indicates cotton is the predominant fiber. A small tolerance (often +/- 3%) is usually permitted between the stated and actual fiber content, but intentional mislabeling is illegal. Proper fiber identification and percentage listing are key.

3.3 Common abbreviations demystified

Especially when dealing with supplier specification sheets or technical documents, you’ll encounter abbreviations for fiber types. Knowing these common shorthand notations is helpful for quick fiber identification.

| Abbreviation | Full fiber name | Key characteristic |

|---|---|---|

| CO | Cotton | Breathable, soft |

| PL | Polyester | Durable, wrinkle-resistant |

| EL | Elastane/Spandex | Stretch |

| VI | Viscose (rayon) | Soft, good drape |

| WO | Wool | Warm, insulating |

| LI | Linen | Highly breathable, textured |

| PA | Polyamide (nylon) | Strong, elastic |

| AC | Acetate | Silky feel, moderate durability |

| RA | Ramie | Strong, linen-like |

| SE | Silk | Lustrous, smooth |

3.4 Key considerations for US market compliance

For businesses selling in the United States, compliance with the FTC (USA) textile labeling rules is mandatory. Key requirements under the Textile Fiber Products Identification Act include:

- Fiber content: Listed accurately by generic name and percentage weight in descending order.

- Country of origin: Clearly stating where the garment was manufactured (e.g., “Made in Vietnam”).

- Manufacturer/importer identification: Identifying the responsible business, often via an RN Number or full business name.

While care instructions are mandated by a separate care labeling rule, they are closely related and typically appear on the same or an adjacent label. Adhering to these rules is vital for legal market access and maintaining trustworthiness. Seeking specific legal counsel for definitive guidance is recommended, as regulations can be complex.

4. Choosing the right mix: Strategic fabric selection for your clothing line

4.1 Aligning composition with garment type

Effective fabric selection hinges on matching the material’s properties, derived from its composition, to the garment’s intended end-use. There’s no single “best” fabric; the right choice depends entirely on function. For example:

- T-shirts and other basics typically prioritize comfort and breathability. 100% cotton or cotton/polyester blends are common choices, balancing softness with durability and ease of care.

- Activewear demands stretch, moisture-wicking capabilities, and durability. Polyester/spandex blends or nylon blends excel here due to their performance fiber properties.

- Outerwear often requires durability, wind resistance, and potentially water resistance or insulation. Polyester, nylon, or robust blends are frequently used.

- Dresses might prioritize drape, softness, or a specific look. Viscose, silk certain cotton weaves, or blends incorporating these fibers might be suitable.

Choosing a fabric composition that doesn’t align with the garment’s purpose can lead to poor performance and customer dissatisfaction, regardless of the garment’s aesthetic appeal.

4.2 Understanding your target customer’s priorities

Beyond the garment type, understanding your specific target market is crucial for fabric selection. Different customer segments value different attributes:

- Some prioritize comfort above all, seeking softness and breathability.

- Others focus on durability and longevity, favoring robust materials like strong polyester blends or denim that withstand frequent wear and washing.

- Style-conscious consumers might be drawn to unique textures, luxurious drape, or trendy materials.

- Price sensitivity is a major factor for many; poly-blends often offer a good balance of performance and affordability.

- A growing segment is eco-conscious, actively seeking sustainable options like organic cotton, recycled polyester (rPET), linen, or Tencel™.

Defining your ideal customer profile helps narrow down fabric choices that resonate with their specific customer needs and values.

4.3 Balancing quality, cost, and production needs

Selecting fabrics involves navigating a constant balance between desired quality, acceptable cost, and production practicalities. Generally, higher quality fibers command higher prices. Effective cost management requires careful consideration of these trade-offs relative to your brand’s positioning and target retail price.

Working with suppliers necessitates clear communication regarding material specifications – not just the fiber content but also weight, finish, and color standards – to ensure consistency across production runs. Be mindful of minimum order quantities (MOQs), as suppliers often require purchasing a certain amount of fabric, which can be a challenge for smaller businesses.

Finding reliable partners through careful supplier negotiation and vetting is key to managing sourcing and achieving production efficiency while maintaining quality standards.

4.4 The role of fabric composition in sustainability perception

In today’s market, fiber choice significantly influences how consumers perceive a brand’s commitment to sustainability. Choices range across a spectrum:

- Natural fibers: Cotton, linen, hemp, wool.

- Synthetic fibers: Polyester, nylon, acrylic.

- Recycled fibers: Recycled polyester made from plastic bottles, recycled cotton.

- Semi-synthetic/man-made cellulosic fibers: Viscose, lyocell, modal.

Each category carries a different environmental impact related to water usage, chemical processing, energy consumption, and end-of-life biodegradability. Using materials like organic cotton or recycled polyester signals a commitment to reducing environmental footprint, which can enhance brand appeal for conscious consumers.

While sometimes associated with higher costs, incorporating sustainable textiles can be a valuable differentiator.

5. Beyond the label: Verifying composition when necessary

5.1 When might verification be needed?

While labels provide the stated composition, situations arise where independent fabric verification becomes prudent for quality assurance and risk management. Consider performing checks or seeking formal testing in these scenarios:

- New supplier: When initiating a relationship with an unproven vendor, verifying their materials ensures they meet specifications.

- Inconsistent batches: If you notice variations in feel, appearance, or performance between different production runs of the same item.

- Supplier disputes: If received goods clearly don’t match the agreed-upon specifications or samples.

- Customer complaints: Persistent feedback regarding unexpected texture, poor durability, or adverse reactions potentially linked to fiber content.

- Suspected mislabeling: If the fabric’s behavior contradicts the label.

- High-value orders: For critical or expensive orders where material accuracy is paramount.

- Incoming quality check: As part of a routine inspection process for key materials.

These checks help mitigate risks associated with incorrect materials impacting product quality and brand reputation, potentially involving different textile testing methods.

5.2 Basic identification insights

Simple observations can offer preliminary clues but are not reliable for definitive fiber identification, especially with blends.

- Visual inspection: Look at sheen, texture, and weave/knit structure. Polyester often has a slight sheen compared to the matte look of cotton.

- Feel test: Assess softness, smoothness, coolness, stiffness, or warmth against the skin. Linen feels cool, while wool feels warmer.

Some sources mention the burn test, where a small fiber sample is exposed to flame to observe its reaction. However, this method has significant limitations and risks:

- Hazardous: Involves open flames and potentially harmful fumes. Proper safety precautions are essential.

- Unreliable for blends: Distinguishing individual fibers within a blend is extremely difficult, if not impossible, with this method.

- Not definitive: Requires significant experience to interpret results, which can still be misleading.

Basic tests offer hints at best; they are not substitutes for professional analysis when accuracy is required.

5.3 The professional standard: Lab testing for certainty

For precise and reliable composition analysis, the only definitive method is sending fabric samples to a specialized third-party lab testing facility. These labs use sophisticated textile testing methods to determine the exact fiber types and percentages. Compliance verification often necessitates lab reports. This approach is advisable when:

- Resolving supplier disputes regarding material composition.

- Ensuring adherence to legal labeling requirements.

- Performing critical quality control on high-value or sensitive materials.

- Investigating significant quality inconsistencies.

While lab testing involves a cost, it should be viewed as an investment in quality assurance, risk management, and maintaining brand integrity, especially when dealing with substantial orders or specific performance requirements.

6. Related questions

6.1 What’s the most common fabric composition for basic t-shirts?

For basic t-shirts, several common compositions cater to different priorities. 100% cotton remains a popular choice due to its excellent breathability and soft feel, offering classic comfort. However, it can be prone to shrinkage and wrinkling.

Cotton/polyester blends, typically ratios like 60/40 or 50/50, are extremely prevalent. These blends offer a balance: retaining some of cotton’s softness while gaining polyester’s durability, wrinkle resistance, and reduced shrinkage, often at a lower cost. They generally dry faster than pure cotton as well.

Another increasingly popular option, especially for a softer feel and better drape, is the tri-blend, commonly combining polyester, cotton, and rayon. These shirts are known for their exceptionally soft texture and comfortable fit but can sometimes be more expensive and may have a higher potential for pilling over time compared to standard cotton or cotton/poly blends.

The choice often depends on the desired feel, performance characteristics, price point, and how well the fabric takes printing.

6.2 How does fabric composition affect printing or embroidery results?

Fabric composition plays a significant role in the success and appearance of printing and embroidery. Natural fibers like cotton are highly absorbent, making them ideal for water-based inks used in techniques like screen printing and direct-to-garment (DTG) printing, generally resulting in vibrant prints.

Synthetic fibers like polyester, being less absorbent and essentially plastic-based, require different approaches. Sublimation printing works well on light-colored polyester, while specialized inks and techniques are needed for screen printing to ensure proper adhesion and prevent dye migration.

For embroidery, fabric stability is paramount. Fabrics that stretch excessively or are very lightweight can pucker or distort during the embroidery process, compromising the design’s sharpness.

Tighter weaves or knits, often found in more stable cottons or polyester blends with minimal stretch, generally provide a better base. Smoother fabric surfaces also tend to yield crisper print details compared to heavily textured fabrics.

6.3 Can I always rely on the supplier’s stated fabric composition?

While reputable suppliers strive for accuracy, it’s prudent to exercise caution rather than assuming automatic supplier reliability, especially when working with new vendors or sourcing very low-cost materials. Building long-term relationships with trustworthy suppliers who consistently deliver quality is ideal.

For crucial orders or new partnerships, always request detailed spec sheets outlining the exact composition, weight, and other relevant parameters. Ordering samples for your own evaluation before committing to bulk production is a vital quality control step.

For ongoing assurance or high-stakes orders, consider periodic spot testing or sending samples to a third-party lab, particularly if inconsistencies arise. Due diligence is key to ensuring you receive the materials you pay for.

6.4 Are sustainable fabric compositions significantly more expensive?

Often, sustainable fabric options do carry a higher cost compared to their conventional counterparts, although this is not universally true and the gap is narrowing for some materials. Factors contributing to the higher price include:

- Certifications: Processes like obtaining GOTS certification for organic cotton involve audits and specific farming practices that add expense.

- Scale: Some sustainable fibers are produced on a smaller scale than conventional materials like standard polyester or cotton.

- Processing: Creating fibers like recycled polyester from post-consumer waste involves collection, cleaning, and reprocessing steps.

- Raw material cost: Sometimes the base materials are more expensive.

However, recycled polyester can sometimes be cost-competitive with virgin polyester, depending on market conditions. Businesses need to weigh the increased cost against their brand value, target market’s willingness to pay a premium, and the marketing benefits associated with sustainability claims.

6.5 How much does fabric composition impact garment shrinkage?

Fabric composition is a major factor influencing garment shrinkage. Natural fibers like cotton, wool, and rayon/viscose generally have a higher tendency to shrink when exposed to heat and moisture during washing and drying compared to most synthetic fibers. Polyester, nylon, and acrylic are inherently more stable and resistant to shrinkage.

Blending fibers is a common strategy to mitigate shrinkage; for example, a cotton/polyester blend will typically shrink significantly less than a 100% cotton garment under the same washing conditions. However, composition isn’t the only factor.

Fabric construction and finishing processes applied during manufacturing also play crucial roles. Always providing accurate care instructions based on the final garment’s composition and construction is essential for helping customers minimize unwanted shrinkage.

Read more:

Understanding and strategically choosing fabric composition serves as the essential quality foundation for any apparel brand aiming for sustained business success. Throughout this guide, we’ve navigated the fundamentals: defining what constitutes composition, exploring the diverse world of natural, synthetic, and blended fibers, decoding the critical information on fabric labels for smart sourcing and compliance, and outlining how to align fiber choices with garment type, customer needs, cost, and sustainability goals. We also touched upon verifying composition when necessary.

These aren’t just technical details; they are key takeaways directly impacting product quality, manufacturing costs, customer satisfaction, and ultimately, your brand’s reputation. Applying this knowledge proactively during product development and sourcing empowers businesses to make informed decisions that resonate with their target market and support their operational goals.

Mastering fabric composition is a significant step towards building a successful and trusted clothing line. Should you require specialized guidance on complementary elements like labels, tags, or packaging solutions tailored to your apparel needs, seeking expert advice can provide valuable support in your journey.