Heat Transfer vs. Woven Labels: Which is Right for Your Clothing?

Choosing the right label is critical for clothing brands and manufacturers. Are you deciding between woven and heat transfer labels? Are you weighing cost, durability, and aesthetics? The wrong choice can hurt your brand image, lead to label failure, or detract from your designs. This decision impacts both initial costs and long-term branding.

This guide compares heat transfer and woven labels, outlining their pros and cons. You’ll gain insights into cost, durability, design options, and application methods. Make an informed decision that aligns with your brand, enhances your garments, and stands the test of time. Avoid common mistakes and select the perfect label for your needs.

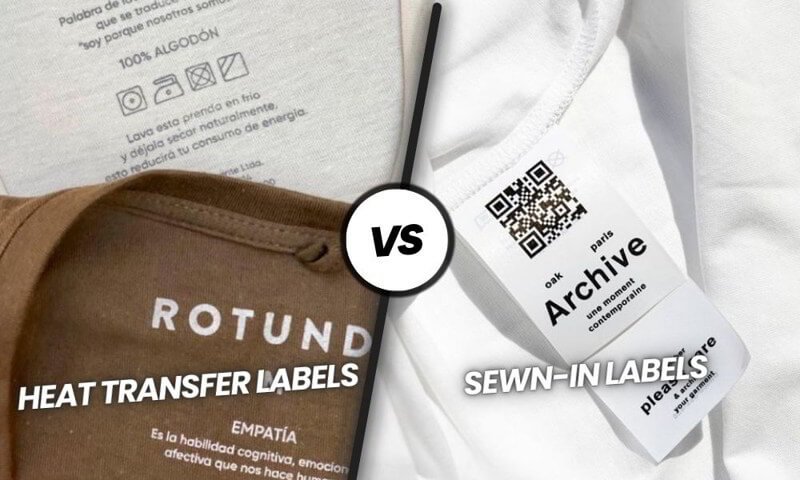

1. Head-to-head comparison: Heat transfer vs. woven labels

1.1 Durability and longevity: How long will they last?

Woven labels are generally considered the champions of durability. Their woven construction makes them exceptionally resistant to washing, fading, and fraying. A well-made woven label will typically last the entire lifecycle of the garment, enduring countless washes and wears.

Heat transfer labels, while offering good durability, are more susceptible to cracking, peeling, or fading over time, particularly with frequent washing and exposure to high heat. The longevity of a heat transfer label depends heavily on the quality of the ink and the precision of the application process.

For maximum longevity, woven labels are generally the superior choice. However, high-quality heat transfer labels, applied correctly, can offer good durability, especially for garments that are not washed frequently.

1.2 Design capabilities: Detail, color, and complexity

Heat transfer labels excel in reproducing full-color images, photographic designs, gradients, and extremely fine details. This is due to the digital printing process used, which allows for a wide color gamut and precise image reproduction.

Woven labels, while capable of intricate designs, have limitations in reproducing color gradients and extremely fine details. The design is created by weaving threads together, which inherently limits the achievable level of detail compared to printing. Woven labels offer unique woven texture.

If your design includes a photograph or complex gradients, heat transfer is the only viable option. For classic logos and text-based designs, woven labels offer a beautiful, textured look.

1.3 Look and feel: Aesthetics and texture

Woven labels possess a classic, textured, and high-end feel. Their woven construction adds a touch of luxury and sophistication, often associated with premium brands and artisanal craftsmanship. Heat transfer labels, on the other hand, create a smooth, seamless, “no-label” feel. This can be particularly desirable for garments worn close to the skin, such as activewear or underwear, where a bulky label might cause irritation, making them an ideal tagless solution.

Consider the overall aesthetic of your brand. Woven labels convey a sense of tradition and quality, while heat transfer labels offer a modern, minimalist look.

Heat transfer labels are generally more cost-effective, especially for small runs and complex designs. This is because the setup costs for heat transfer are typically lower than those for woven labels. Woven labels can be more expensive, particularly for small quantities, due to the more involved weaving process and higher setup costs.

However, pricing for both label types varies depending on factors like size, design complexity, and order quantity. Get quotes for both heat transfer and woven labels to compare pricing for your specific needs. Consider both upfront costs and the long-term value each option provides.

1.5 Application method: Heat press vs. sewing

Heat transfer labels are applied using a heat press machine, which uses heat and pressure to bond the label to the fabric. This is a relatively fast and easy process, making it suitable for tagless applications. However, it does require investing in a heat press machine.

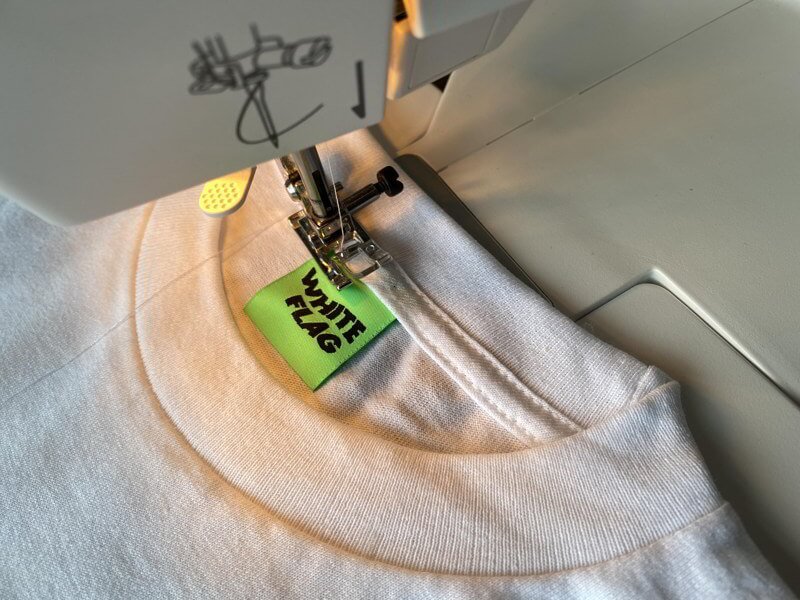

Woven labels are typically sewn onto the garment, either by hand or using a sewing machine. This is a more time-consuming process and requires sewing skills or outsourcing to a professional seamstress. However, sewing provides a permanent attachment that is highly durable.

The application method is a significant factor. If you’re looking for a fast, easy, and tagless solution, heat transfer is ideal. If you prefer a permanent, classic attachment, sewing is required for woven labels.

1.6 Fabric compatibility: Which label works best where?

Heat transfer labels are generally compatible with a wide range of fabrics, including delicate materials like silk and satin. However, caution is needed with heat-sensitive fabrics, as the heat application process could potentially damage them. Woven labels are best suited for fabrics that can withstand sewing without puckering or damage. Very thin or delicate fabrics might be prone to puckering when a woven label is sewn on.

Always test a sample on your chosen fabric before committing to a large order, regardless of the label type. This allows you to assess compatibility and ensure the best possible results.

2. Making the right choice: Heat transfer or woven?

2.1 When to choose heat transfer labels

Heat transfer labels are the ideal choice in several scenarios:

- Full-color designs and photographic images: When your design requires vibrant colors, gradients, or photographic reproduction.

- Tagless applications: When you want a smooth, seamless feel against the skin, particularly for activewear or underwear.

- Small runs: When you need a smaller quantity of labels and want to minimize setup costs.

- Budget constraints: When you’re seeking a more economical labeling solution.

- Delicate fabrics: When you’re working with materials that might be damaged by sewing, but can handle the heat application process.

2.2 When to choose woven labels

Woven labels are the preferred option in these situations:

- Classic branding: When you want to convey a sense of tradition, quality, and craftsmanship.

- High-end garments: When you’re creating premium apparel and want a label that reflects that luxury.

- Maximum durability: When you need a label that will last the entire lifespan of the garment, withstanding countless washes.

- Textured look: When you want to add a tactile, dimensional element to your branding.

- Permanent attachment: When you prefer the secure, classic feel of a sewn-on label.

2.3 Can’t decide? Consider a hybrid approach

It’s not always an either/or situation. Some brands may benefit from a hybrid approach, using both heat transfer and woven labels for different garments or applications. For example, you might use woven labels for your main branding on outerwear and heat transfer labels for size and care information on t-shirts. This allows you to leverage the advantages of each label type strategically.

3. FAQs about heat transfer and woven labels

3.1 Which label type is more eco-friendly?

The environmental impact depends on the specific materials used. Woven labels can be made from recycled yarn or organic cotton, making them a sustainable choice. The eco-friendliness of heat transfer labels depends on the type of ink used. Some inks are more environmentally friendly than others (e.g., water-based inks). It’s best to inquire with your supplier about the specific materials and processes used for each label type.

3.2 Can I use a household iron to apply heat transfer labels?

While it’s possible to use a household iron for heat transfer labels, it’s not recommended for professional results. A heat press provides consistent temperature and pressure across the entire label, which is crucial for proper adhesion and long-term durability. An iron can lead to uneven heating and pressure, resulting in poor adhesion, cracking, or peeling.

3.3 How do I prevent my heat transfer labels from cracking or peeling?

Preventing cracking and peeling involves several factors:

- Use high-quality heat transfer labels: Choose labels from a reputable supplier.

- Apply them correctly: Use a heat press and follow the manufacturer’s instructions precisely for temperature, pressure, and dwell time.

- Follow care instructions: Wash and dry garments according to the recommended guidelines (usually cold water, gentle cycle, and air drying or low heat).

3.4 What is the minimum order quantity for each label type?

Minimum order quantities (MOQs) vary significantly between suppliers. Generally, heat transfer labels have lower MOQs than woven labels, often starting at a few hundred pieces. Woven labels typically have higher MOQs, sometimes starting at several hundred or even a thousand pieces, due to the more complex weaving process.

3.5 Do heat transfer labels have a “plastic” feel?

Modern heat transfer labels, especially those using high-quality plastisol or water-based inks, have a very soft and flexible feel. When applied correctly, they should integrate smoothly with the fabric and not feel stiff or overly “plastic-like.” The feel can vary depending on the specific type of heat transfer material used, so it’s always best to request samples.

4. Packlove – Your partner for heat transfer and woven labels

With over 8 years of experience in the garment industry, specializing in labels and tags for clothing, Packlove is your trusted partner for both high-quality heat transfer and woven labels. We understand the nuances of each label type and can help you choose the perfect solution to elevate your brand and enhance your garments.

Whether you need the vibrant detail of heat transfer or the classic elegance of woven, we offer expert advice and guidance throughout the entire process, from initial design consultation to material selection and production. We’ll consider your specific design, budget, garment type, and branding goals to ensure your labels perfectly represent your vision.

Contact Packlove today for a consultation or to request a quote! Let us help you create labels that make a lasting impression. Visit Packlove to learn more.

Read more:

Choosing between heat transfer and woven labels ultimately comes down to your specific needs and priorities. There’s no single “best” option; each type offers unique advantages and trade-offs. Carefully consider factors like durability, design capabilities, aesthetics, cost, application method, and fabric compatibility. Weigh the pros and cons discussed in this guide, and select the label that best aligns with your brand image, target market, and overall garment design. By understanding the key differences and making an informed decision, you can ensure your labels enhance your garments, elevate your brand, and leave a lasting positive impression. Explore your options further, and don’t hesitate to contact Packlove for personalized guidance and expert advice on choosing the perfect labeling solution for your brand.