Pad Printing: 3D And Irregular Surface Printing for Apparel

Understand what is pad printing and its powerful application for apparel branding. This guide details the unique indirect offset process, using a flexible silicone pad to transfer sharp, high-resolution designs from etched plates onto challenging surfaces, including those that are irregular, curved, or three-dimensional.

Learn why it’s ideal for clothing tags, trims, and comfortable tagless labels where other methods struggle. Discover its advantages over screen printing for fine detail and surface conformity, understand key components like pads, plates, and inks, and grasp practical considerations like artwork prep and cost-effectiveness for your business needs.

1. What is pad printing?

1.1 The core concept

Pad printing, sometimes referred to as Tampography (a term often used in Europe), stands out among various printing processes due to its unique mechanism. Fundamentally, pad printing is an indirect offset printing technique. Unlike direct methods where ink might be applied straight onto a surface, pad printing involves an intermediary step. The desired image is first etched into a flat plate, following principles similar to the gravure method where recessed areas hold ink.

A soft, flexible silicone pad then lifts this inked image from the plate. This pad, acting as the transfer vehicle, subsequently presses onto the object, depositing the ink to recreate the image. This image transfer happens because of carefully controlled ink tackiness and the pad’s release properties. Imagine a highly advanced rubber stamp, but one capable of precisely transferring fine details picked up from an etched surface onto potentially uneven objects.

1.2 Why it matters for apparel

The brilliance of pad printing for the apparel industry lies precisely in that indirect transfer using a flexible silicone pad. Clothing items and their associated tags or components are rarely perfectly flat. Consider labels sewn into curved seams, tagless care instructions printed directly onto textured fabric near the neckline, or even small logos on plastic toggles or zipper pulls. Pad printing excels here because the soft silicone pad flexibility allows it to conform remarkably well to these irregular surfaces, curved surfaces, and textures.

This ability to handle complex surfaces and essentially perform 3D object printing on a small scale ensures that branding and essential information can be applied clearly and precisely, even on challenging substrates common in garment manufacturing. This makes pad printing a valuable tool for achieving high-quality apparel tag printing where other methods might struggle.

2. How does the pad printing process work?

2.1 Preparing your design

Central to the pad printing process is the printing plate, commonly referred to as a cliché. This plate performs the crucial function of holding the ink in a precisely recessed version of the desired artwork – whether that’s a logo, care instructions, or other branding elements. The design is transferred onto the plate surface, and then the image area is etched down slightly into the plate material. This image etching creates tiny wells that will hold the ink.

The etched artwork can be created through chemical etching processes or, increasingly common for fine detail and repeatability, via laser engraving. Plates themselves are typically made from either photopolymer plates or hardened steel plates. The choice depends on the required print longevity and budget. Regardless of material, the cliché is the master copy of the image within the printing machine.

2.2 The ink transfer cycle

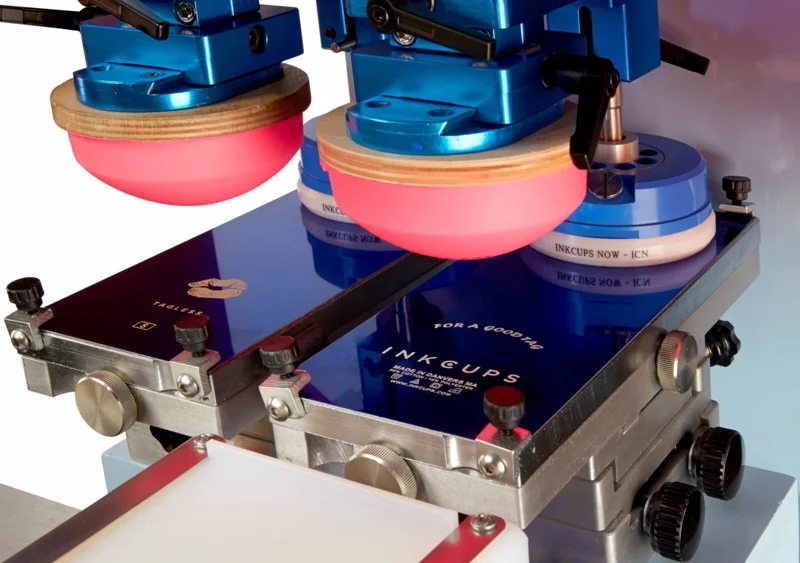

The actual pad printing process operates through a distinct, cyclical series of mechanical movements centered around ink transfer. Modern machines predominantly use a sealed ink cup system for efficiency and cleanliness. Here’s a typical pad printing cycle:

- Inking the cliché: The sealed ink cup, which holds the ink supply and has a sharp ceramic or metal ring edge, slides across the etched cliché. This action floods the etched artwork area with ink. As the cup moves away, its ring edge performs a ‘doctoring’ action, scraping excess ink off the surface of the cliché, leaving ink only within the recessed etchings.

- Image pickup: The silicone pad presses down onto the etched area of the cliché. A key phenomenon occurs here: a small amount of solvent evaporation from the surface of the ink in the etch makes the ink tacky. This tackiness allows the ink to adhere preferentially to the silicone pad when the pad lifts away.

- Image transfer: The pad, now carrying the inked image, moves over to the item being printed. The pad presses down onto the substrate. The ink’s slightly higher affinity for the substrate compared to the treated silicone pad, combined with the pressure application, causes the ink layer to release from the pad and adhere to the product, faithfully reproducing the design.

- Cycle reset: The pad lifts off the substrate and returns to its starting position, ready to pick up ink for the next cycle. Simultaneously, the ink cup typically moves back over the etched area on the cliché, covering the image to prevent the ink within from drying out and preparing for the next inking step.

The sealed ink cup is particularly advantageous because minimizing solvent evaporation helps maintain consistent ink properties and reduces fumes compared to older open inkwell systems.

3. Essential components driving pad printing quality on textiles

3.1 The transfer vehicle

The silicone pad, often made of specialized silicone rubber, acts as the crucial transfer vehicle in pad printing. Its quality and characteristics directly influence the final print. Two primary attributes determine a pad’s suitability for a specific job: pad shape and pad hardness.

The choice of shape depends largely on the size and geometry of the image and the printing area. Hardness, however, is critical for adapting to the substrate shape adaptation required in apparel. A harder pad generally transfers finer detail more crisply and works well on flat, smooth surfaces. Conversely, a softer pad offers greater flexibility, allowing it to conform better to curved surfaces or wrap around textures often found in tagless printing directly onto fabric.

For apparel tags, selecting the right pad involves considering these trade-offs. Printing sharp, small text on a smooth polyester label might benefit from a slightly harder pad. However, applying a tagless label onto a textured cotton knit might require a softer pad to ensure complete ink transfer across the uneven surface, even if it slightly sacrifices the ultimate edge sharpness of very fine details. Consistent print quality relies heavily on using well-maintained pads appropriate for the specific application.

3.2 Holding your brand image

The printing plate or cliché holds the master image that gets transferred. For businesses dealing with apparel tags, the choice often comes down to two main types: photopolymer plates and steel plates.

- Photopolymer plates are essentially light-sensitive plastic plates. They are generally easier and less expensive to process, making them a common choice for short-to-medium production runs or situations with frequent design changes – often suitable for small businesses managing diverse but smaller batches of tags. Image etching is typically done through UV exposure and washout processes.

- Steel plates are significantly more durable and can last for hundreds of thousands, even millions, of impressions. While the initial cost is higher, they are the preferred option for very long runs of the same design. Etching is usually done chemically or via laser engraving, offering high precision.

The decision hinges on expected volume per design. If a brand anticipates printing tens of thousands of the same tag design, the longevity of steel might justify the cost. However, for brands with many styles requiring smaller batches of unique tags, the cost-effectiveness and quicker turnaround of photopolymer plates often make more sense. The plate life cycle needs to align with production realities.

3.3 The medium matters

Selecting the correct pad printing ink is paramount for labels and tags destined for clothing, where wash durability is non-negotiable. While various ink types exist, solvent-based inks are frequently used for their versatility across different tag materials.

The critical factor for achieving robust wash resistance on textiles relies on using a hardener. Most textile pad printing inks suitable for durable applications are 2-component systems, meaning the ink must be mixed with a specific hardener before printing. This chemical additive initiates a curing process that significantly boosts the ink’s adhesion and ink resistance to washing, abrasion, and chemicals. Printing without the appropriate hardener will likely result in poor durability.

Substrate compatibility is also key. Different tag materials (e.g., polyester, nylon, cotton blends, coated paper) may require specific ink series formulated for optimal adhesion. Additives like thinners might be necessary to adjust ink viscosity based on ambient conditions and desired print characteristics. Always conduct thorough testing: apply the chosen ink system (with hardener) to the actual tag material or fabric and perform rigorous wash testing cycles to ensure the print meets the brand’s durability standards.

For brands prioritizing responsibility, inquire about inks meeting safety standards like Oeko-Tex Standard 100, especially for items intended for close skin contact or children’s wear. Reputable suppliers can provide documentation for compliant ink series. While less common for standard tags due to curing requirements, UV curable ink systems also exist in pad printing, offering instant curing under UV light.

| Ink Type | Typical Use | Wash Resistance (Tested w/ Hardener) | Common Substrates |

|---|---|---|---|

| 1-Component Solvent | Promotional items, some plastics (low wash req.) | Poor to Fair | Plastics, coated paper |

| 2-Component Solvent | Apparel tags, tagless, industrial parts | Good to Excellent | Polyester, nylon, cotton*, plastics |

| UV Curable | Medical devices, electronics, some tags | Good to Excellent (substrate dependent) | Plastics, glass, metals, some fabrics |

3.4 Ink management

Modern pad printing relies heavily on the ink cup system, specifically the sealed ink cup design. This component serves multiple roles. It acts as the ink reservoir, holding the supply of ready-to-use ink. The edge of the cup, typically a precision-ground ceramic ring, presses firmly against the flat surface of the cliché. This creates a tight seal that prevents ink leakage. As the cup slides across the cliché to ink the etched image, this same ring performs the doctor blade function, cleanly wiping away all excess ink from the plate surface, leaving ink only in the etched areas.

The primary advantage of the sealed ink cup over older open inkwell systems is significant solvent evaporation control. By keeping the ink enclosed, solvent loss is minimized. This leads to several benefits:

- Reduced ink consumption.

- More stable ink consistency (viscosity remains stable longer).

- Lower volatile organic compound (VOC) emissions and less odor in the workspace.

- Cleaner operation overall, as ink is contained within the cup and the etched portion of the plate.

For businesses focused on consistent quality and a more controlled production environment, the sealed ink cup is the standard and highly recommended system.

4.1 Unmatched precision on challenging surfaces

One of the standout strengths of pad printing is its capacity for precision printing, delivering exceptional text clarity and high resolution even on difficult substrates. This method excels at reproducing fine detail printing, such as tiny care symbols, registered identification numbers (RN numbers), or intricate elements within logos.

Crucially, this precision is maintained even when printing on small components or surfaces that aren’t perfectly flat – think tags sewn into curves, slightly textured materials, or very small brand identifiers. Where other methods might struggle with ink bleed, distortion on curves, or filling in fine negative spaces on complex shapes, the gentle transfer mechanism of the silicone pad allows for crisp, clear results.

4.2 The go-to for tagless labels

Pad printing has become a leading technology for producing tagless garment printing. The primary driver for this apparel industry trend is enhanced wearer comfort – eliminating the physical tag removes a common source of irritation. Pad printing facilitates this by applying brand and care information directly onto the fabric.

When the correct ink system is used and properly cured, these tagless labels are not only comfortable but also durable enough to withstand repeated washing. Furthermore, the ink layer deposited by pad printing is often very thin, resulting in a soft hand feel that is barely perceptible against the skin, a distinct advantage over potentially thicker prints from other methods.

4.3 Material versatility

While excellent for standard tag materials like polyester, satin, nylon, or coated papers, pad printing’s versatility extends further within the apparel realm. Its inherent substrate compatibility allows for effective printing on a wide range of materials often used for trims and accessories.

This includes various plastics, coated substrates, and even smooth metals. This adaptability means brands can potentially use the same core technology to apply consistent branding across not just labels but also other small hardware components, enhancing brand cohesion throughout the product. Its capability for fabric printing directly, as seen in tagless applications, further underscores this flexibility.

4.4 Cost-effectiveness for certain scenarios

For small business apparel brands, pad printing can offer compelling cost-effectiveness, particularly when dealing with multiple designs or frequent style changes. While the initial purchase of equipment represents an initial investment, the setup costs per design are relatively low compared to some other methods. Creating an etched plate is often less expensive and faster than preparing a dedicated screen for screen printing, especially for multi-color designs requiring multiple screens.

Therefore, for brands producing moderate quantities across a diverse range of styles – a common scenario in fashion – pad printing can achieve good run size efficiency. The consumable costs per print are generally manageable, making the overall cost per print attractive in these specific production contexts, even if it’s not always the absolute cheapest method for massive single-design runs.

5. Pad printing vs. screen printing

5.1 Print detail & resolution

When comparing print quality comparison specifically for the fine details often required on apparel tags, pad printing generally offers an advantage. Its ability to transfer a very thin, precise layer of ink allows for excellent reproduction of fine lines and extremely small text, such as intricate care symbols, fiber content abbreviations, or small logo elements.

Screen printing, while capable of high quality, can sometimes struggle with maintaining open areas in very fine reverse text or achieving the same level of sharpness on minute details due to the nature of ink passing through a mesh screen. For applications demanding the highest level of detail and clarity in minimal space, pad printing often comes out ahead in resolution comparisons.

5.2 Surface handling

The fundamental difference in how ink is applied dictates each method’s strength regarding surface geometry. Pad printing, with its flexible silicone pad, inherently excels at conforming to irregular surfaces, curves, and textures. This makes it highly suitable for printing tags located near seams, directly onto slightly uneven fabric for tagless application suitability, or onto small, potentially rounded trim components.

Screen printing, conversely, performs best on flat surfaces. While specialized techniques exist for screen printing on curves, it’s generally more complex and less inherently suited to the types of surface conformity challenges often presented by garment tags and tagless applications compared to the natural adaptability of a pad.

5.3 Ink layer & feel

The amount of ink deposited differs significantly between the two processes, impacting the final hand-feel, particularly crucial for tagless comfort. Pad printing typically applies a very thin ink layer. When using appropriate flexible textile inks, this results in a print that is soft, pliable, and often barely noticeable against the skin – a major plus for tagless labels. Screen printing, depending on the mesh count, ink type, and technique used, often deposits a thicker ink thickness.

While modern screen printing inks can achieve a relatively soft feel, the ink layer can sometimes be more perceptible than a pad printed equivalent, which might be a consideration for garments where maximum softness and minimal feel are paramount. The comfort comparison often slightly favors pad printing for tagless applications due to this thinner, more flexible deposit.

5.4 Economic factors for small apparel businesses

Evaluating small business economics reveals distinct cost profiles. Pad printing often involves lower setup costs per design, as creating a cliché is typically less expensive than burning a screen. This benefits businesses with many different tag designs produced in moderate volumes. However, the initial investment in pad printing equipment can be higher than basic screen printing setups.

Screen printing tends to have higher setup costs per design but can achieve a lower cost per print comparison on very high-volume runs of a single design due to faster potential speeds. Consumable costs also differ – pads wear out and need replacement, while screens require maintenance and eventual remeshing. The best choice depends heavily on the brand’s specific production model: diversity of designs versus volume per design, influencing overall run size efficiency.

5.5 Workflow & speed considerations

In terms of production speed and workflow comparison, single-color pad printing can be quite rapid, with automated machines achieving high impression rates suitable for typical tag volumes. However, multi-color printing with pad printing adds significant complexity. Each color requires a separate cliché, pad, and print cycle, and precise registration challenges can slow down the process considerably.

Screen printing, particularly with multi-station rotary presses, can be extremely fast for high-volume production, even for multi-color designs, provided the items can be handled efficiently. For high-volume, multi-color tagless applications on flat areas, screen printing might offer a speed advantage. For single-color tags or applications on complex shapes, pad printing’s efficiency is notable.

6. Practical considerations before adopting pad printing

6.1 Artwork design for optimal etching

Successful pad printing begins with well-prepared artwork. For optimal results that translate effectively onto the etched plate, artwork preparation should ideally involve vector graphics. Vector files define shapes mathematically, ensuring clean, sharp lines regardless of scaling, which is crucial for the plate etching requirements. While pad printing is renowned for handling fine details exceptionally well, certain graphic design tips can further enhance outcomes.

Extremely fine lines or very small negative spaces should adhere to minimum thickness specifications provided by the plate maker to ensure they etch cleanly and transfer reliably. While pad printing can handle solid areas better than some other fine-detail methods, exceptionally large solid blocks might occasionally require specific ink or pad considerations for perfectly uniform coverage, though fine detail remains its primary strength.

6.2 Material testing

Perhaps the most critical step before committing to pad printing for apparel tags or tagless applications is thorough substrate testing. It is strongly advised to conduct ink adhesion tests using the specific ink system on the actual tag materials or garment fabrics intended for production. Different textiles and coatings behave differently, and what adheres perfectly to polyester might fail on treated cotton or nylon.

Beyond initial adhesion, rigorous wash testing is essential quality control. Simulate real-world washing and drying cycles multiple times (e.g., 20, 30, 50 cycles) to verify that the print maintains its integrity, color, and adhesion according to the brand’s durability standards. While surface pre-treatment methods exist to improve ink adhesion on very difficult plastics, they are rarely necessary for the typical materials used in apparel tags and labels. Confirming ink performance through testing prevents costly production failures and ensures customer satisfaction.

6.3 Process management

Achieving consistent, high-quality results with pad printing involves diligent process management and routine maintenance. Key areas include:

- Ink viscosity management: Solvent-based inks thicken over time due to evaporation. Regularly monitor ink viscosity and add thinner sparingly as recommended by the ink manufacturer to maintain optimal flow and transfer characteristics.

- Pad care: Proper cleaning silicone pads extends their life and ensures clean prints. The standard method is using specialized adhesive tape to lift residual ink between cycles. Avoid excessive use of harsh solvents, which can degrade the silicone. Regularly inspect pads for wear or damage.

- Cliché maintenance: Keep the printing plate clean. Wipe away any dried ink or debris carefully, following manufacturer guidelines, to prevent print defects.

- Environmental factors: Be mindful of the printing environment. High humidity can significantly slow solvent evaporation and ink drying/curing times, potentially affecting print quality and adhesion, especially with 2-component inks. Maintaining a relatively stable temperature and humidity level aids quality consistency.

Attention to these operational details helps minimize variations and ensures the printing process runs smoothly.

6.4 Initial investment

Bringing pad printing in-house requires an initial investment in equipment. Evaluating the right pad printer machine depends on several factors specific to the business’s needs:

- Color capability: Will printing be exclusively single-color, or are multi-color tags required? Multi-color machines are more complex and expensive.

- Print size: Determine the maximum image area needed for the largest planned tags or tagless prints.

- Production volume: Estimate the expected daily or weekly output to ensure the chosen machine’s speed and duty cycle are adequate.

For many small apparel operations focusing on tags or tagless labels, reliable bench-top models often provide sufficient capability without the footprint or cost of large industrial machines. This equipment evaluation involves balancing current needs with potential future growth. It’s an investment that should be weighed against the benefits of control, flexibility, and potential cost savings compared to outsourcing, considering the specific production scenario.

7. Related questions about pad printing for apparel

Yes, achieving multi-color pad printing on apparel tags is certainly possible. This is accomplished using specialized machines equipped with multiple pads and clichés, one for each color in the design. The process involves sequential printing steps where each color is applied individually.

However, the critical challenge in multi-color work is ensuring precise color registration – the exact alignment of each color layer relative to the others. Achieving perfect registration adds complexity to the setup and operation, often requires more sophisticated equipment, and generally increases the cost and potentially slows down the production speed compared to single-color printing.

7.2 How durable are pad printed tagless labels after washing?

The durability and wash resistance of pad printed tagless labels depend heavily on using the correct materials and processes. When the appropriate pad printing ink system – typically a 2-component ink correctly mixed with its specified hardener – is selected for the specific fabric type and properly cured, the resulting print can be very durable.

Properly executed pad printed tagless labels can often withstand numerous domestic wash cycles, frequently meeting industry standards of 30 to 50 washes or more without significant degradation. However, achieving this level of performance relies entirely on correct ink selection, mixing, application, and curing parameters. Thorough wash testing on the actual garment fabric before full production is absolutely essential to verify the durability meets the brand’s requirements.

7.3 What are the safety considerations for pad printed inks on clothing?

Ink safety is a vital consideration when printing directly onto clothing or labels that will have prolonged skin contact. Reputable ink manufacturers serving the apparel industry offer pad printing inks specifically formulated to comply with stringent international apparel regulations and clothing safety standards.

Look for inks that meet requirements such as Oeko-Tex Standard 100 or relevant aspects of the Consumer Product Safety Improvement Act (CPSIA) in the US, particularly for children’s wear. It is crucial for brands to request and verify compliance documentation or certificates from their ink suppliers to ensure the inks used are safe for the intended application and end-user.

7.4 Is pad printing suitable for very small start-up clothing brands?

Pad printing presents both opportunities and challenges for a start-up business in the clothing brand space. Its ability to handle diverse designs with relatively low setup costs per design makes it attractive for brands launching with multiple styles or needing frequent updates to tag information. The quality and versatility, especially for tagless labels, can align well with brands aiming for a premium feel.

However, the primary hurdle is the initial equipment investment. Purchasing even a basic bench-top pad printer, plates, pads, and inks represents an upfront cost that must be weighed. Very small start-ups might initially find outsourcing options for tag printing or using simpler, lower-investment methods like pre-made stock labels or heat transfer labels more financially feasible while they establish their production volume and cash flow.

Pad printing becomes more viable as volumes increase or when the specific benefits are key strategic elements for the brand from the outset.

Read more:

Pad printing (or Tampography) offers distinct advantages for enhancing apparel branding. Its core strengths lie in delivering remarkable precision printing on challenging surfaces, its exceptional suitability for creating comfortable and durable tagless labels, and its versatility across various materials used in clothing labels and trims. This technique allows brands to apply detailed logos, care instructions, and other essential information clearly and effectively, both on traditional tags and directly onto garments themselves.

Choosing the optimal labeling or branding method often benefits from comparing different technologies. For tailored advice on implementing pad printing or evaluating how it stacks up against other solutions for your unique needs, consulting with specialists can provide valuable clarity. Resources like Packlove offer expertise in this area and can assist with navigating these choices.