Polyester: Pros, Cons, Uses and Recycled Options

Polyester, a synthetic polymer derived primarily from petroleum, stands as a cornerstone material in countless industries worldwide. Its unique properties lend themselves to a vast range of applications, making it both incredibly useful and increasingly scrutinized. Understanding this material requires looking at both sides of the coin.

This overview will cover the essential aspects: the functional benefits (Pros), the environmental and practical limitations (Cons), its widespread Uses from apparel to automotive parts, and the development and importance of Recycled Options like rPET.

1. Defining Polyester: More Than Just a Name

Polyester isn’t a single material but rather a category of polymers (large molecules composed of repeating subunits) distinguished by the presence of an ester functional group linkage within their main chemical chain. Essentially, it is a synthetic fiber, meaning it is man-made through chemical processes, typically utilizing chemicals derived from petroleum.

This origin places polyester firmly under the broad classification of plastics. The term “polyester” covers a range of materials, much like how “wood” describes various types like pine or oak, each with slightly different characteristics but sharing a fundamental composition.

1.1 PET: The Workhorse of Polyester Fabrics

When discussing polyester in the context of textiles and apparel, the specific type most frequently encountered is Polyethylene Terephthalate, commonly known as PET. Its dominance in the industry stems from a practical balance between desirable properties (like durability and wrinkle resistance) and relatively low production cost. Many are familiar with PET as the material used for single-use beverage bottles (PET bottles), a connection that highlights its widespread use and hints at the potential for recycling this material into fabrics.

1.2 A Glimpse at Other Polyester Types

While PET is prevalent, other polyester varieties exist for specific needs. PCDT Polyester (Poly-1, 4-cyclohexylene-dimethylene terephthalate) is one such type, primarily differing from PET in its greater elasticity and often enhanced durability. These traits make it suitable for items like heavy-duty upholstery or industrial applications, though it’s less common in standard apparel.

Another area gaining attention is plant-based polyester. These are emerging alternatives derived from renewable resources like cane sugar or corn instead of petroleum. Their main appeal lies in sustainability, potentially offering better biodegradability or a reduced carbon footprint compared to traditional polyester. However, current limitations often include higher cost, possibly different performance characteristics (like strength or feel), and lower overall market availability.

- PCDT Polyester: More elastic and durable than PET, used in heavy-duty applications.

- Plant-Based Polyester: Derived from renewables (cane sugar, corn), potential sustainability benefits (biodegradability, lower footprint), but often higher cost and different performance.

2. The Starting Point: Petroleum & Alternatives

The production process for conventional PET polyester begins with its basic chemical building blocks: ethylene glycol and terephthalic acid (or its derivative, dimethyl terephthalate – DMT). These core ingredients are typically synthesized from crude oil, also known as petroleum.

This reliance on fossil fuels represents a significant environmental consideration for the material. It’s worth noting that alternative pathways exist, particularly for plant-based polyester, which utilize plant sources such as cane sugar to derive the necessary chemicals, offering a route away from direct petroleum dependence.

3. Creating the Polymer and Fibers

The transformation from basic chemicals into usable fiber involves several key steps in the production process. First is polymerization: ethylene glycol and terephthalic acid are reacted together under specific conditions of heat and pressure. This chemical reaction links the smaller molecules into long, repeating chains, forming the polymer known as polyester. The resulting substance, initially molten, is then extruded (pushed out), cooled, and typically chopped into small pellets or chips.

These chips are the intermediate form. To create polyester fibers, the chips are melted again. The molten polyester is then forced through a device with very fine holes, called a spinneret (similar in concept to a showerhead extruding water). As the polyester exits the spinneret and cools, it solidifies into fine, continuous strands – these are the polyester fibers.

Depending on the intended final fabric, these fibers can either be kept as long, continuous filaments or cut into shorter, predetermined lengths known as staple fibers (similar to the length of cotton fibers).

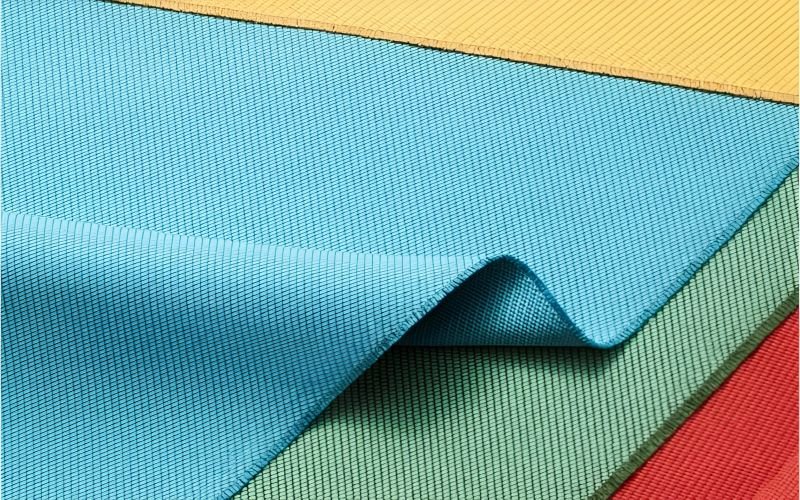

4. Weaving the Final Fabric

Once the polyester fibers (either long filament or shorter staple) have been produced, the next stage in textile manufacturing is to spin them into yarn. This process twists the individual fibers together, creating a continuous thread suitable for making fabric.

This polyester yarn is then used in conventional fabric creation methods, primarily weaving (interlacing yarns at right angles) or knitting (interlooping yarns), to produce large rolls of polyester fabric. These fabric rolls are the raw material that apparel manufacturers and other textiles users purchase to create finished goods.

5. Durability and Resilience: Why It Lasts

One of polyester’s defining properties is its exceptional durability. The fibers possess high intrinsic strength, making fabrics resistant to tearing, stretching, and abrasion (wear and tear from rubbing). For businesses in the apparel industry, this translates directly into tangible benefits:

- Longer-lasting clothing: Garments can withstand more wear and washing cycles before showing signs of damage.

- Resilient labels: Printed or woven brand and care labels maintain their integrity and legibility, resisting fraying or disintegration during use and laundering.

- Strong poly mailers: Packaging made from polyester films offers reliable tear resistance, protecting garments during shipping.

Furthermore, polyester inherently resists damage from many common chemicals and exhibits good resistance to UV radiation, making it a suitable choice for outdoor gear and applications exposed to sunlight. Its overall robust performance is a key reason for its widespread use.

6. Handling Moisture: Water-Resistant, Not Absorbent

Polyester fibers exhibit a hydrophobic nature, meaning they naturally repel water rather than absorbing it. This characteristic leads to distinct advantages and disadvantages regarding moisture management properties:

- Pros: The primary benefit is being quick-drying. Since the fibers themselves don’t hold much water, polyester garments dry much faster than absorbent natural fibers like cotton. This is highly valued in outerwear and activewear, where fabrics are designed with structures that help move moisture vapor away from the skin (often termed moisture-wicking, though for polyester, this relies more on capillary action within the fabric structure than fiber absorption). The water resistance is also beneficial for care labels needing to withstand washing.

- Cons: Because polyester doesn’t absorb moisture well, it can feel clammy or sticky against the skin when the wearer sweats heavily, as the moisture sits on the surface. The hydrophobic fibers also tend to attract and hold onto oils (like body oils), which can sometimes lead to odor retention issues compared to natural fibers.

It is interesting to note that Microfiber fabrics, often made from polyester, can hold significant amounts of water. This isn’t because the fiber itself becomes absorbent, but because the extremely fine filaments create a vast surface area that traps water effectively between the fibers, making them suitable for cleaning cloths or towels despite the base material being hydrophobic.

7. Keeping Shape: Wrinkle Resistance and Stability

A significant practical advantage of polyester lies in its excellent shape retention and resistance to wrinkling. Compared to natural fibers like cotton or linen, which crease easily, polyester fabrics tend to spring back to their original form. This property offers several benefits:

- Reduced Ironing: Garments made from polyester require significantly less ironing, saving time and effort for the end consumer.

- Maintained Appearance: Clothes maintain a smoother, neater look throughout the day, even during travel.

- Crisp Tags and Labels: Branding elements like woven or printed tags and labels remain flat and legible after washing and wearing, resisting creasing or distortion.

Furthermore, polyester exhibits good dimensional stability, meaning it resists shrinking or stretching out of shape during washing or wear, contributing to the longevity and consistent fit of garments and the integrity of attached elements. These properties enhance both convenience and the perceived quality of the final product.

8. Heat Sensitivity: A Crucial Factor

A critical property of polyester that requires careful management is its heat sensitivity. Unlike natural fibers that tend to char or burn at high temperatures, polyester melts. This characteristic has several important practical implications across the product lifecycle:

- Printing: Processes like heat transfer or sublimation printing on polyester garments or labels demand precise temperature control. Exceeding the melting point can damage the fabric or cause dyes to migrate improperly.

- Ironing: Polyester garments must be ironed using low heat settings. Direct contact with a hot iron can easily melt or permanently glaze the fabric surface. This information is crucial for care labels.

- Drying: High heat settings in clothes dryers should be avoided, as they can cause irreversible shrinkage or damage to the fibers. Air drying or tumble drying on low heat is recommended.

- Storage: Avoid storing polyester items in direct contact with high heat sources (like radiators or heating vents).

Understanding and respecting polyester’s reaction to heat is essential for manufacturers during production and for consumers during care to maintain the product’s integrity.

9. Color & Dyeing Considerations

The chemical nature of polyester, specifically its hydrophobic (water-repelling) quality, dictates the type of dyes required to color it effectively. Standard dyes used for natural fibers like cotton won’t bond properly. Instead, polyester requires a specific class of dyes known as disperse dyes. These dyes are designed to penetrate the non-polar structure of the polyester fiber.

When dyed correctly using appropriate disperse dyes and processes, polyester generally exhibits good colorfastness. This means the colors are resistant to fading from washing, exposure to light, and rubbing. However, the dyeing process itself typically requires high temperatures (often under pressure) and significant water usage, which contributes to the overall environmental impact associated with polyester production. Proper wastewater treatment is crucial in mitigating this aspect. These properties related to dyeing are important considerations for achieving desired colors and ensuring their longevity.

10. Affordability Factor: Cost vs. Performance Balance

A major factor driving polyester’s widespread use in the textile industry is its affordability. Generally speaking, polyester is one of the relatively inexpensive fibers to produce, particularly when compared to many natural fibers such as silk, wool, or often even cotton.

This lower production cost translates into lower material costs for manufacturers, enabling businesses to offer finished apparel and other textile products at more competitive price points. The decision to use polyester frequently involves balancing its attractive cost against its specific performance characteristics and potential drawbacks, making it a key element in pricing strategies and market positioning.

11. Breathability Considerations

One of the inherent properties of polyester fibers is their relatively low breathability. The fiber itself does not allow much air or moisture vapor to pass through it. While the specific weave or knit structure of a polyester fabric can be engineered to allow for some level of air permeability, dense constructions made purely from polyester tend to trap more heat and moisture against the skin compared to highly breathable natural fibers like cotton.

This lack of inherent breathability is why 100% polyester garments can sometimes feel warm or clammy, especially in hot or humid conditions. To counteract this limitation and improve wearer comfort, polyester is very commonly blended with other fibers. A poly-cotton blend, for example, combines polyester’s durability and wrinkle resistance with cotton’s superior softness and breathability. Blending is a widely used strategy to achieve a more balanced set of fabric properties.

12. Core Apparel Uses: Strengths and Weaknesses

Polyester’s unique combination of properties makes it suitable for a wide range of apparel and clothing applications, though its strengths in one area might be offset by weaknesses in another:

- Activewear/Sportswear: Polyester dominates this category due to its excellent durability, resistance to stretching, and the ability of specific fabric structures to achieve effective moisture-wicking. Its quick-drying nature is also a major plus. Potential weakness: Odor retention can sometimes be an issue compared to natural fibers.

- Outerwear/Jackets: High water resistance and wind resistance make polyester ideal for raincoats, windbreakers, and insulated jackets. Its durability stands up well to outdoor conditions. Weakness: Can lack the breathability desired for high-exertion activities unless specifically engineered with vents or membranes.

- Dresses, Suits, Shirts: Valued here for its excellent wrinkle resistance, shape retention, and relatively low cost. Offers a crisp appearance with minimal upkeep. Weakness: Lower breathability might make some styles less comfortable for warm weather or all-day wear compared to natural fiber alternatives.

Businesses select polyester for these applications by weighing its beneficial properties (like cost, durability, wrinkle resistance) against its limitations (like breathability or heat sensitivity) based on the specific requirements of the garment and the target consumer.

13. Branding & Trims: Polyester Labels, Tags, and Ribbons

Polyester is an extremely common and practical choice for branding elements like labels, tags, and decorative ribbons on apparel and accessories. Its suitability stems from several key characteristics:

- Printability: Polyester surfaces readily accept various printing methods used for logos, care instructions, and branding messages. Techniques like heat transfer, sublimation, screen printing, and digital printing can achieve sharp, clear results.

- Durability: Essential for items that endure repeated washing and wear, polyester labels and tags resist fraying, tearing, and fading, ensuring brand identification and care information remain legible for the garment’s lifespan.

- Feel/Finish: Polyester fibers can be processed to create different textures and sheens, such as smooth satin weaves or crisp taffeta finishes, allowing brands to choose trims that match their desired aesthetic.

- Cost-effectiveness: Compared to options like silk or high-quality cotton, polyester often provides a more budget-friendly solution for producing the necessary volume of labels, tags, and ribbons required for apparel production.

14. Shipping Solutions: The Practicality of Poly Mailers

Polyester, often used in the form of plastic film (sometimes as pure polyester, sometimes blended or coated with materials like polyethylene), is the standard material for poly mailers used in packaging and shipping apparel. Their popularity among e-commerce businesses and wholesalers stems from purely functional benefits:

- Water resistance: The material protects clothing items inside from rain, spills, and general moisture encountered during transit.

- Tear strength / Durability: Poly mailers are significantly more resistant to punctures, rips, and tears during handling and shipping compared to paper envelopes or less robust packaging.

- Lightweight: The low weight of the material helps to minimize shipping costs, particularly important for businesses shipping large volumes.

- Opacity: Most poly mailers are opaque, ensuring privacy for the contents within the package.

- Cost-effectiveness: For shipping soft goods like apparel, poly mailers are typically a more economical packaging choice than bulkier and heavier cardboard boxes.

15. The Power of Blends: Enhancing Fabric Properties

While 100% polyester fabrics have their place, polyester is very frequently used in blended fabrics. This involves combining polyester fibers with one or more other fiber types, most commonly natural fibers like cotton. The prime example is poly-cotton, a staple in the apparel industry.

The primary purpose of creating a blended fabric is to leverage the desirable properties of each component fiber, aiming for a final material that offers a better overall balance of performance than either fiber alone. In the case of poly-cotton:

- Polyester contributes: Durability, wrinkle resistance, shape retention, faster drying, and often lower cost.

- Cotton contributes: Softness against the skin, enhanced breathability, and better moisture absorption (reducing clamminess).

By blending, manufacturers can create fabrics that are durable and easy to care for, yet more comfortable and breathable than pure polyester. Other common blends include poly-spandex (adding stretch) or poly-viscose (enhancing softness and drape), all designed to optimize fabric performance for specific end uses.

| Property | 100% Cotton | 100% Polyester | 50/50 Poly-Cotton Blend |

|---|---|---|---|

| Breathability | High | Low | Medium |

| Wrinkle Resistance | Low | High | Medium-High |

| Durability | Medium | High | High |

| Drying Time | Slow | Fast | Medium-Fast |

| Softness | High | Varies | Medium |

| Shape Retention | Low-Medium | High | Medium-High |

16. The Environmental Concerns: From Production to Disposal

Despite its utility, conventional polyester production and use raise significant environmental concerns throughout its lifecycle, impacting overall sustainability:

- Fossil Fuel Dependence: The primary raw materials for most polyester are derived from petroleum, a non-renewable resource. Its extraction and processing carry environmental burdens.

- Energy Intensive Production: Manufacturing polyester fibers from raw chemicals is an energy-intensive process, contributing to greenhouse gas emissions if the energy sources are fossil fuel-based.

- Microplastic Pollution: Every time polyester garments are washed, they shed tiny plastic fibers known as microplastics. These fibers enter waterways through wastewater, polluting oceans, rivers, and potentially entering the food chain.

- Non-biodegradable: Most common types of polyester do not readily break down in the natural environment. Discarded polyester items persist in landfills or ecosystems for potentially hundreds of years.

- Dyeing Process: The use of disperse dyes and the requirement for high heat and large amounts of water in the dyeing process can lead to water pollution if wastewater treatment is inadequate.

Understanding these aspects of its environmental impact is crucial for businesses making responsible sourcing decisions.

17. Recycled Polyester (rPET): A Step Towards Circularity?

Recycled Polyester, commonly abbreviated as rPET, offers a more sustainable alternative to virgin polyester. It is most frequently produced using post-consumer PET bottles as the raw material, although post-industrial waste can also be utilized. The process involves collecting, cleaning, and melting down the PET plastic, which is then extruded into new polyester fibers.

The benefits of using rPET are notable:

- Reduces landfill waste by giving PET bottles and other plastic items a second life.

- Lessens the demand for virgin petroleum (fossil fuels), conserving non-renewable resources.

- Generally requires less energy and water in its production compared to manufacturing virgin polyester.

However, rPET is not a perfect solution and has limitations:

- Washing rPET fabrics still releases microplastics into the environment.

- The recycling process itself consumes energy and resources and can generate its own waste streams.

- The quality of rPET can sometimes vary depending on the source materials and processing methods.

- PET plastic cannot be recycled infinitely; it often undergoes “downcycling” where the quality degrades with each recycling loop, limiting true circularity.

To ensure authenticity, businesses can look for certifications like the Global Recycle Standard (GRS), which verifies the recycled content in the final product. While not a complete answer to polyester’s environmental challenges, rPET represents a significant step towards improving the sustainability of using polyester materials.

18. Future Trends & Responsible Choices

Innovation continues in the textile industry, with ongoing development in areas like plant-based polyester. These alternatives, derived from renewable resources, aim for improved sustainability characteristics, such as potential biodegradability or a lower carbon footprint compared to petroleum-based options.

However, for businesses making decisions now, several practical responsible choices can be made regarding polyester use:

- Consider Recycled Options: Evaluate the feasibility of using rPET for products where its performance is suitable and aligns with the brand’s sustainability values.

- Vet Suppliers: Partner with manufacturers who demonstrate transparent and responsible production practices, particularly concerning energy use and wastewater treatment during dyeing and finishing.

- Design for Durability: Create high-quality, long-lasting products to extend their usable lifespan and reduce the frequency of replacement.

- Educate Consumers: Provide clear care instructions emphasizing washing less often, using cold water, and potentially suggesting the use of microfiber-catching laundry bags or filters to help minimize microplastic shedding during home laundering.

Making conscious decisions about material selection and encouraging responsible use contributes to mitigating the environmental impact associated with polyester.

19. Making Informed Decisions: Is Polyester Right for Your Brand?

Choosing the right materials is a critical aspect of decision making for any apparel brand. When considering polyester, it requires weighing its significant advantages against its notable drawbacks. The pros often include lower cost, excellent durability, and specific performance features like high wrinkle resistance and water resistance. The cons primarily revolve around its negative environmental impact, potential lack of breathability, and crucial heat sensitivity.

To determine if polyester (virgin or rPET) fits your needs, consider these key questions:

- Your Brand Ethos: Does using a synthetic, petroleum-derived (or even recycled) material align with your brand’s core values and story? Are you positioned as luxury, budget-friendly, performance-focused, or eco-conscious?

- Your Target Customer: What factors do your customers prioritize most? Are they driven by price, longevity, sustainability credentials, or tactile comfort?

- Product Requirements: What specific performance characteristics are non-negotiable for the apparel item, label, tag, or packaging you are creating? Is durability paramount? Is breathability essential?

- Cost Implications: How does the material choice impact your production budget, final product pricing, and overall profit margins?

- Sustainability Goals: Does your brand have specific environmental targets? Is using virgin polyester acceptable, or should alternatives like rPET or other fibers be actively sought?

Ultimately, the decision isn’t simply yes or no. It depends on the specific context of your brand, your product, and your market. Understanding the trade-offs detailed throughout this discussion allows for a more strategic and informed material selection.

20. Related Questions

20.1 Is polyester comfortable to wear?

The comfort of polyester is subjective and depends heavily on several factors. Its inherent low breathability means it can feel warm or clammy in hot conditions compared to natural fibers. While fabric structures can be engineered for moisture-wicking (moving sweat away), the fiber itself doesn’t absorb moisture well. The feel against the skin can vary greatly, from smooth and silky in fine filament fabrics to somewhat artificial in others.

Fabric construction (weave/knit density) and the use of blends, such as poly-cotton, significantly impact perceived comfort by incorporating properties like softness and improved breathability from the other fiber. Therefore, while some polyester garments are very comfortable, particularly performance wear, others might be less so for everyday wear in warm climates.

20.2 How do I care for polyester garments and labels?

Polyester is generally easy to care for, making it popular for everyday garments and durable labels. Here are basic guidelines, though always check the specific care label on the item:

- Washing: Most polyester items are machine washable. Use cool or warm water; avoid hot water, as high temperatures can damage the fibers due to polyester’s heat sensitivity.

- Drying: Tumble dry on a low heat setting or, ideally, air dry. High heat in dryers can cause shrinkage, permanent wrinkles, or even melting in extreme cases.

- Ironing: If ironing is needed, use the coolest setting on your iron and iron quickly. Consider using a pressing cloth.

- Static/Odor: Polyester can sometimes build up static cling (a fabric softener can help) and may retain odors more than natural fibers, occasionally requiring more thorough washing.

Following these care instructions helps maintain the appearance and longevity of polyester products.

20.3 Can polyester labels be printed clearly?

Yes, polyester labels are exceptionally well-suited for printing. The material provides a stable and often smooth surface that allows for sharp details and vibrant colors using various common printing methods. Techniques frequently used include:

- Heat Transfer: Applying pre-printed designs using heat and pressure.

- Sublimation: A process where dye turns into gas under heat and permeates the polyester fibers, creating very durable, full-color prints.

- Screen Printing: Applying ink through a mesh screen.

- Digital Printing: Direct printing from a digital file.

The resulting prints on polyester labels generally exhibit good clarity and excellent durability, holding up well through repeated washing and wear when the appropriate printing method and inks are used.

20.4 Is recycled polyester (rPET) the same quality as virgin polyester?

The quality of recycled polyester (rPET) can be highly comparable to that of virgin polyester, especially with modern advancements in recycling technology. For many standard apparel and textile applications, including clothing, bags, and labels, the performance characteristics (like strength, colorfastness, and feel) are often indistinguishable between rPET and virgin materials.

However, the final quality can vary depending on factors like:

- Source Material: The cleanliness and consistency of the feedstock (e.g., clear PET bottles versus mixed-color or contaminated plastics).

- Recycling Process: Different mechanical and chemical recycling methods can yield slightly different results in terms of fiber purity and consistency.

While minor variations might exist, high-quality rPET is widely considered a viable and effective substitute for virgin polyester in a vast range of products without compromising essential performance attributes.

Read more:

Polyester undeniably plays a central role in the modern apparel and textile industry. As a synthetic fabric, its popularity is built on a foundation of versatility, exceptional durability, and significant cost-effectiveness. Key performance advantages like wrinkle resistance, shape retention, and water resistance make it suitable for countless applications, from high-performance clothing to everyday wear and essential branding elements like labels and tags, as well as practical shipping solutions like poly mailers.

However, these benefits must be weighed against significant drawbacks, primarily its considerable environmental impact stemming from fossil fuel origins and microplastic pollution, along with limitations like lower breathability compared to natural fibers and sensitivity to heat. Understanding this full picture – including the potential of alternatives like rPET – is crucial for businesses aiming to make informed and responsible material choices that align with their brand values, product requirements, and sustainability goals.

For personalized guidance on choosing the best materials, including polyester options for your specific apparel, labels, or packaging needs, reach out to the experts at Packlove.