Sleeve Length Garment Measurements: Reduce Returns

Confused about sleeve length for accurate apparel sizing? This guide clarifies the crucial industry definition, emphasizing the standard Center Back Neck (CBN) measurement method for consistency. Learn why this technique surpasses simple arm measurements, ensuring proper fit across body types. Master the step-by-step process for reliable results, vital for reducing costly returns, enhancing customer satisfaction, and building brand trust. Gain the precise knowledge needed to measure sleeves accurately and elevate your garment quality standards.

1. Defining sleeve length in garment measurement

1.1 The standard definition

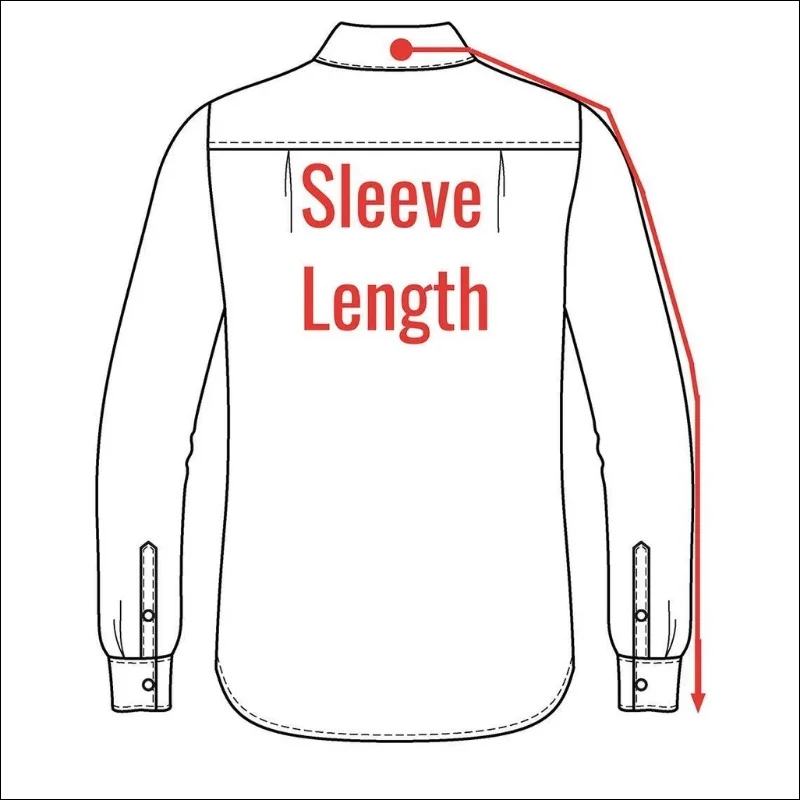

Sleeve length is a crucial garment dimension influencing overall clothing fit and shirt sizing. Unlike simply measuring the arm itself, the standard industry approach defines sleeve length starting from a specific anatomical landmark: the Center Back Neck (CBN).

This measurement start point is the prominent bone located at the base of the neck, precisely in the center of the back. The measurement then proceeds across the shoulder and down the arm to a predetermined endpoint, typically the wrist.

1.2 Why the center back neck (CBN) method is standard

Adopting the Center Back Neck (CBN) as the starting point is a widely accepted measurement technique within the apparel industry. The primary reason for this standard is its ability to provide consistent results across various body types and shoulder widths. Measuring solely from the shoulder seam can introduce significant variations depending on a person’s build and the specific garment’s shoulder construction. The CBN method effectively standardizes the measurement, making it a more reliable metric for achieving consistent garment sizing standards across different individuals and styles.

1.3 Sleeve length vs. arm length vs. shoulder width

It’s important to distinguish the standard sleeve length measurement from simply measuring arm length or shoulder measurement. Arm length typically refers to the measurement from the shoulder joint down to the wrist. Shoulder width measures the distance across the top of the shoulders.

The standard sleeve length, starting from the CBN, incorporates a portion of the upper back and shoulder area before continuing down the arm. This comprehensive approach better reflects how a sleeve actually drapes and fits in relation to the wearer’s overall body proportions.

2. The business case: Why accurate sleeve length matters

2.1 Elevating customer satisfaction & fit perception

The fit of the sleeves profoundly impacts how customers perceive a garment’s quality. Sleeves that end correctly at the wrist contribute to a polished and professional garment appearance, signifying attention to detail. Conversely, sleeves that are too short or too long can make an otherwise well-made item look sloppy or ill-fitting.

Achieving a proper fit in the sleeves is therefore essential for enhancing overall customer satisfaction and their positive perception of your brand’s offerings.

2.2 Slashing returns & exchanges

Inaccurate apparel sizing, particularly sleeve length, is a significant driver of product returns and exchanges, especially for online retailers. Each return incurs costs related to shipping, restocking, and potentially lost sales. For a small business, minimizing these returns is crucial for profitability. Consistently accurate sleeve measurements directly address a common fit issue, leading to fewer returns and a healthier bottom line.

2.3 Streamlining inventory & manufacturing communication

Utilizing standardized garment measurement practices, including the precise method for sleeve length, simplifies communication with manufacturers and suppliers. When ordering stock or specifying production requirements for wholesale clothing, clear and consistent measurements prevent costly misunderstandings and errors.

Specifying the exact measurement unit (inches/cm) ensures everyone involved is aligned. This accuracy contributes to smoother inventory management and more reliable production outcomes.

2.4 Building brand trustworthiness & expertise

Providing accurate sizing information, detailed in a clear clothing fit guide that includes specifics like sleeve length, demonstrates a commitment to quality and customer needs. This attention to detail builds brand trust and positions your business as knowledgeable and reliable within the apparel space.

3. Mastering the measurement: The standard body method step-by-step

3.1 Preparation

To begin, you will need a flexible measuring tape. Ensure the individual being measured is standing relaxed and naturally, without holding tension in their shoulders or arms.

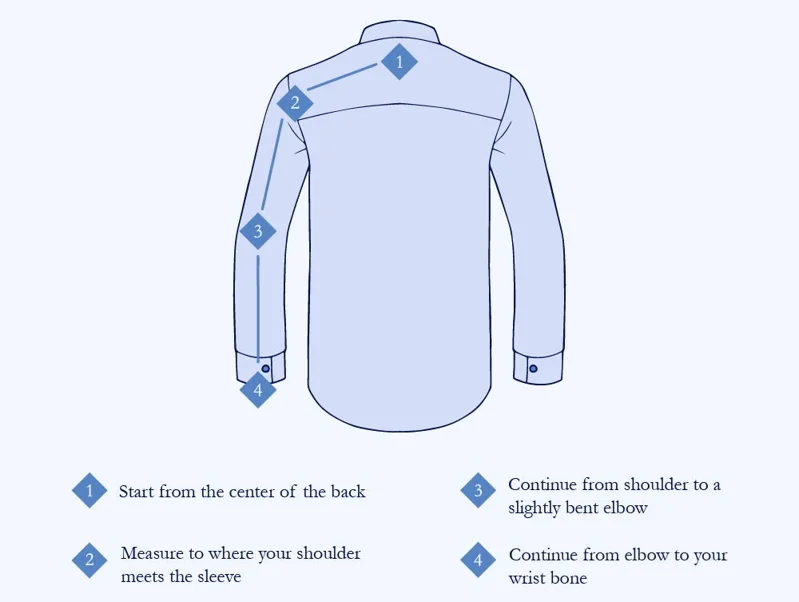

3.2 Locating the starting point (CBN)

Feel for the prominent bone at the base of the neck, centered on the spine. This landmark is the starting point (CBN), or center back neck. Place the beginning of the measuring tape directly on this point.

3.3 Following the measurement path

Guide the measuring tape smoothly across the top of the shoulder, hitting the natural shoulder point (the bone at the outer edge of the shoulder). Continue down the arm, allowing the tape to follow the natural curve without pulling tightly or leaving slack.

3.4 Correct arm position

The correct arm position is crucial for an accurate measurement. The arm should hang relaxed at the side with a slight arm bend at the elbow. Measuring with a completely straight, stiff arm will result in a sleeve length that is too short when the arm is naturally bent during wear.

Conversely, an exaggerated bend can lead to an overly long measurement. The slight bend mimics natural movement and ensures the sleeve provides adequate coverage.

3.5 Determining the end point

The measurement typically ends at the prominent wrist bone. However, depending on the intended garment fit and style (e.g., a formal dress shirt versus a casual jacket), the endpoint might extend slightly further, perhaps to the base of the thumb or even the center of the palm when unbuttoned (though the measurement itself is usually taken to the wrist bone). Consistency in choosing the endpoint (wrist/hand) for your brand’s sizing is key.

3.6 Recording the measurement accurately

Read the measuring tape carefully at the chosen endpoint. Record the measurement precisely, ensuring you note the measurement unit (inches/cm). For custom tailoring or bespoke garments, noting measurements to the nearest 1/4 inch or even 1/8 inch can improve accuracy and final fit.

4. Visualizing the fit: How shirt and jacket sleeves should look

4.1 The dress shirt standard

For a classic dress shirt, the sleeve, when buttoned, should ideally end right at the wrist bone, where the hand begins. This ensures the cuff is fitting properly without creeping up the forearm or swallowing the hand.

When worn under a jacket, proper jacket and shirt sleeve coordination is key to a polished appearance. Typically, about 1/4 to 1/2 inch of the shirt cuff should be visible beyond the end of the jacket sleeve.

When unbuttoned, the same dress shirt sleeve will naturally fall longer, often reaching near the first knuckle of the thumb. This apparent extra length isn’t an error; it’s necessary to allow for comfortable arm movement, such as bending the elbow or reaching forward, without the sleeve riding up the arm. The cuffs (buttoned) act as an anchor, securing the sleeve position correctly at the wrist during normal wear.

4.3 Cuff design & fit interaction

The specific cuff design options (e.g., barrel cuffs, French cuffs) and the tightness of the fastening also play a role in where the sleeve hem ultimately rests. A tighter cuff size or a bulkier cuff style might cause the sleeve to sit slightly higher on the wrist compared to a looser or simpler cuff, even if the overall sleeve length measurement is identical.

4.4 Considerations across garment types

While the fundamental measurement techniques for determining sleeve length remain consistent, the desired *finished* length can vary between different types of garments. For instance, the target length for a jacket sleeve or outerwear might differ slightly from that of dress shirts, reflecting design intent, layering considerations, and functional requirements of the specific apparel category.

5. Addressing common variations and challenges

5.1 Handling asymmetrical arms/shoulders

It’s not uncommon for individuals to have a slight difference between left/right arm length or experience uneven shoulders. If asymmetry is suspected or noticeable, it’s advisable to measure both arms separately using the standard CBN method.

For ready-to-wear garments, a common practice is to use the longer measurement for production and inform customers that minor adjustments may be needed by a tailor. For businesses offering custom clothing or made-to-measure services, recording both measurements allows for custom sleeve lengths, providing a superior fit for these clients.

5.2 The reality of fabric shrinkage

Fabric shrinkage and garment care are practical realities that businesses must consider. Many natural fibers (like cotton) and even some synthetics can shrink after washing and drying. The amount of shrinkage varies significantly depending on the material composition and weave. It’s essential to understand the typical shrinkage rates for the fabrics used in your garments.

Some manufacturers incorporate a shrinkage allowance into their patterns, cutting sleeves slightly longer (pre-wash vs. post-wash measurement considerations). Communicating potential shrinkage and providing proper care instructions helps manage customer expectations. For instance, some brands specializing in fitted shirts explicitly account for shrinkage in their initial sizing.

5.3 Body vs. garment measurement

While measuring directly on the body is standard for determining fit, measuring a finished garment laid flat is another common measurement technique. This garment measurement method is frequently used for quality control checks during production, for creating specification sheets, or when customers provide measurements from an existing, well-fitting garment.

It is crucial to always clarify whether provided measurements refer to the body or a flat garment, as the numbers will differ (garment measurements incorporate ease and design elements). Clear communication prevents significant sizing errors.

6. Related questions

6.1 How much should a dress shirt sleeve show under a jacket?

Achieving a polished look often involves showing a specific amount of the dress shirt sleeve cuff beneath the jacket sleeve. The widely accepted standard is to reveal between 1/4 inch and 1/2 inch (approximately 0.6 cm to 1.3 cm) of the shirt cuff. This small detail creates a visual break, adds definition, and contributes to a well-tailored appearance.

6.2 What’s the difference between sleeve length and inseam length?

These are two distinct measurements for different parts of the body and types of garments. Sleeve length measurement, as detailed in this guide, pertains to the arm and is used for shirts, jackets, coats, and other upper-body garments. Inseam length, conversely, measures the interior length of the leg, from the crotch seam down to the ankle or desired hemline, and is used specifically for sizing trousers, jeans, and shorts.

6.3 Can sleeve length be easily altered by a tailor?

Yes, adjusting sleeve length is a common task for a qualified tailor. Shortening a sleeve is generally straightforward, involving removing the cuff, cutting the excess fabric, and reattaching the cuff. However, the ability to alter a sleeve to make it longer is limited by the amount of extra fabric folded into the hem or seam allowance inside the cuff. If insufficient allowance exists, lengthening the sleeve significantly may not be possible without compromising the garment’s look or construction.

6.4 Does sleeve length measurement change if I gain or lose weight?

Generally, the standard sleeve length measurement (from Center Back Neck to wrist) does not significantly change with moderate weight fluctuations. Arm length itself is determined by bone structure. However, substantial weight gain or loss could potentially alter shoulder breadth or posture slightly, which might subtly influence how a sleeve hangs, but the core measurement itself typically remains consistent.

Read more:

Mastering the definition of sleeve length and the standard center back neck (CBN) measurement method is foundational for any successful clothing business. Consistently implementing these accurate practices is essential for achieving a quality fit, directly enhancing customer satisfaction, and significantly reducing costly returns due to sizing errors.

Prioritizing precise sleeve length measurements translates into tangible benefits, elevating your brand’s reputation by demonstrating a commitment to quality apparel and customer experience. While consistent sizing involves many factors, effectively communicating fit through elements like professional labels and tags further supports this goal. For expert assistance with branding solutions that reflect your commitment to quality, turn to Packlove for custom labels, hang tags, and patches that make your apparel stand out.