What Is Fabric Print: Your Easy Guide To Designs On Textiles

Have you ever wondered how cool designs get onto your t-shirts or bags? That’s often done through fabric printing! It’s a way to make everyday items unique and special. This guide will explain fabric printing in simple terms, perfect for everyone.

1. What is fabric print?

Let’s start with the basics. Understanding fabric printing can help you make great choices for your clothes, accessories, or business branding.

1.1 What is fabric printing?

Fabric printing simply means putting designs, pictures, or words onto cloth or fabric. Think of it like printing on paper with your home printer, but this time, it’s for fabric – like the material used for your t-shirts, bags, or curtains.

To do this, we use special inks or materials that are made to stick to fabric and last. These are different from the inks used for paper because fabric stretches, gets washed, and is worn. Fabric printing is a wonderful way to make fabric items look unique, carry a message, show off a cool design, or display a brand logo.

So, when we talk about fabric print, it’s all about adding these designs on textile materials using special ink. This is a popular form of textile customization.

You can print all sorts of things: patterns, drawings, photos, words, company logos, and much more onto different types of textile.

1.2 Why is fabric printing cool?

Fabric printing is popular because it lets you:

- Make your clothes look special and one-of-a-kind.

- Turn your bags into fun accessories that show off your personality.

- Decorate things in your home, like pillows or curtains, to match your style.

- For businesses, it’s a great way for garment decoration, like putting brand names on clothes or logos on team uniforms. This makes them look official and recognizable. This is where custom apparel solutions come in, allowing you to create almost any design you can think of!

1.3 What you will learn in this guide

In this easy guide, you will learn about:

- The most common ways people print on fabric.

- What each printing method is good for, so you can understand printing options better.

- Some fun ideas for things you can make using fabric printing.

By the end, you’ll have a good idea about the types of fabric printing methods for beginners.

2. Common ways to print on fabric

There are several ways to print on fabric. Each method has its own process and works best for different kinds of projects. Let’s look at some common ones.

2.1 Method 1: Screen printing

Screen printing is a classic method for applying designs to fabric.

1. How it works:

Here’s a basic explanation of screen printing on textiles:

- First, a special frame with a fine mesh screen (like a very fine net) is made.

- Your design is turned into a stencil on this screen. This means some parts of the mesh are blocked, and other parts (your design) are left open.

- The screen is placed on top of the fabric. Ink is put on one side of the screen.

- A tool called a squeegee (like a rubber window cleaner) is used to pull the ink across the screen.

- The ink only goes through the open parts of the screen (the stencil) and onto the fabric below. This is how pattern transfer (moving the design) and color application (adding color) happen.

- If your design has more than one color, you need a separate screen for each color. Each color is printed one by one.

- After printing, the ink is usually dried with heat to make it permanent.

2. What it looks and feels like:

Screen prints often have very bright and strong (vibrant colors on fabric). The edges of the design usually look sharp. The print can feel a bit thick on top of the fabric. If many colors are layered, it might feel even thicker. You can often feel the print with your fingers.

3. Pros (Good things about it):

- Very durable fabric printing: Prints last a long time if done well.

- Great for many items: If you need lots of the same design (e.g., 100 t-shirts), it’s often the cheapest per item.

- Bright, vibrant colors that really pop.

- Works on many fabric types, including dark colors.

4. Cons (Not-so-good things):

- Setup costs: Making screens takes time and money, so it’s not great for just one or two items. This is related to the MOQ (Minimum Order Quantity – the smallest number of units you can order), which is often higher for screen printing.

- More colors = more cost: Each color needs a new screen, which adds to the cost.

- Not ideal for photos: Very detailed photos with many shades are hard to do well.

5. Best for:

This method is especially popular for printing t-shirts, particularly for bulk orders of t-shirt designs for events, company logos, band merchandise, or other apparel (clothing). It’s also good for hoodies, tote bags, and uniforms.

2.2 Method 2: Digital printing

Digital printing, also often called DTG (which means Direct-to-Garment), is key for understanding digital printing for custom fabrics.

1. How it works:

Think of it like a big inkjet printer you might have at home, but it prints directly onto fabric, especially t-shirts and other clothes. The printer sprays tiny drops of special fabric ink right onto the cloth to make the full color (using all colors) design.

It can print many colors and details all at once, like a photo. No need for separate screens for each color. Sometimes, especially for dark fabrics, the fabric is treated with a special clear liquid first. This helps the ink stick better and look brighter.

2. What it looks and feels like:

DTG is great for printing photos or designs with lots of details and many shades of color. The print looks very sharp and clear. The ink usually soaks into the fabric, so it often feels very soft fabric print, almost like part of the fabric, especially on light-colored cotton. On dark fabrics (where a white ink layer might be printed first), it can feel a tiny bit thicker, but usually still soft.

3. Pros (Good things about it):

- Perfect for detailed designs: Excellent for photos, artwork with many colors, or complex graphics. You can print photos on fabric easily.

- Good for small orders: Great if you only need one custom item or a few. No big setup cost per design.

- Easy to change designs: You can print a different design on each item without extra setup.

4. Cons (Not-so-good things):

- Slower for very large orders: Printing each item can take longer than screen printing if you need hundreds.

- Can cost more per item for big batches compared to screen printing.

- Best on cotton: Works best on 100% cotton or fabrics with a lot of cotton. Not ideal for pure polyester.

- White ink on darks: While possible and looks good, the white ink base on dark fabrics might feel slightly thicker and may not be as super-durable as colors on light fabrics over many, many washes.

5. Best for:

T-shirts with photos or very colorful, detailed artwork. Custom clothing like personalized gifts (e.g., a t-shirt with a pet’s photo). Small businesses or designers trying out new t-shirt designs.

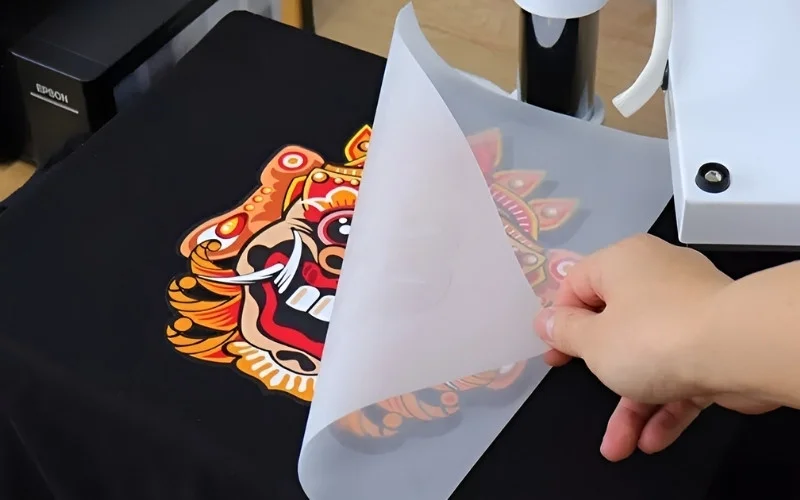

2.3 Method 3: Heat transfer printing

Heat transfer printing is a method that applies designs to fabric in a couple of ways. If you’re asking how does heat transfer printing on fabric work, it involves a design on a special sheet that is then pressed onto the fabric using heat.

1. How it works:

There are two main types:

- Heat Transfer Vinyl (HTV): Your design is cut from a sheet of colored material called vinyl for shirts (it’s like a special fabric sticker). Vinyl comes in many colors, even glitter or metallic.

- Printed Transfers: Your design is printed (often with a special printer) onto printed transfers for fabric (special paper). This is good for full-color designs.

Then, a heat press machine (or heat press) is used. This machine gets very hot and applies strong pressure. The fabric is placed in the machine, the vinyl or transfer sheet is put on top (design side down), and the machine presses them together. The heat and pressure stick the design to the fabric.

2. What it looks and feels like:

The design sits on top of the fabric; it doesn’t soak in. It can be smooth (like vinyl), shiny, matte, or even glittery. It feels like an extra layer on the fabric.

3. Pros (Good things about it):

- Great for names, numbers, and simple logos (e.g., on sports jerseys).

- Works on many fabric types (cotton, polyester, blends).

- Good for small orders or even single items.

- Lots of special effects available (glitter, metallic, glow-in-the-dark).

- Can be quite durable if good materials are used and applied correctly.

4. Cons (Not-so-good things):

- Can feel a bit stiff or like plastic if the design is very large and made of thick vinyl.

- The area under a large design might not be very breathable.

- Very tiny, separate pieces in a design can be tricky to apply. This applies to die-cut designs (cut into a custom shape using a specialized tool) with intricate details.

5. Best for:

Sports jerseys (names and numbers), custom messages on bags or t-shirts, simple logos on hats. This method is also used for items like printed labels.

2.4. Method 4: Dye sublimation printing

Dye sublimation printing uses a special ink and process.

1. How it works:

First, your design is printed onto special transfer paper using these sublimation inks. This paper is placed on the fabric (which must be polyester or have a high polyester content). When heated in a heat press, the ink on the paper turns directly into a gas. This gas then goes into the polyester fibers and becomes a permanent part of them. The ink is in the fabric, not just sitting on top.

Important: This method works best on white or very light-colored polyester fabric. It won’t work well on cotton or dark fabrics because the ink is transparent and mixes with the fabric color.

2. What it looks and feels like:

You can’t feel the print at all! The color is inside the fabric. Prints are usually very bright, clear, and can show amazing detail, like photos. It’s great for vibrant all-over prints.

3. Pros (Good things about it):

- Super permanent fabric print: Won’t crack, peel, or fade easily.

- Amazing, vibrant colors and great detail.

- No feel – the fabric stays soft and natural.

- Very breathable fabric print as the fibers aren’t blocked.

- Great for printing all over a garment.

4. Cons (Not-so-good things):

- Mainly for white or light-colored polyester fabrics or polyester-coated items. Does not work on 100% cotton.

- Won’t show up on dark-colored fabrics.

5. Best for:

Sportswear (jerseys, activewear – because of printing on polyester’s durability and breathability). T-shirts or fashion items with ‘all-over’ prints (if polyester). Custom lanyards, mousepads, fabric banners

3. Which fabric printing method is best?

3.1 Easy-to-read table

Here’s a simple table to help you quickly compare fabric printing methods:

| Feature | Screen Printing | Digital (DTG) | Heat Transfer | Dye Sublimation |

|---|---|---|---|---|

| Feel on Fabric | Can be thick | Soft | Layer on top | No feel |

| Color Detail | Good for bold | Excellent | Good | Excellent |

| How Long it Lasts | Very Good | Good | Good | Excellent |

| Best for Few Items | Not ideal | Yes | Yes | Yes |

| Best for Many Items | Yes | Okay | Okay | Good |

| Best Fabric Type | Most types | Cotton best | Most types | Polyester only |

This table provides a quick comparison of the methods, helping you choose the right option based on your fabric type and project needs.

3.2 Thinking about your needs

There’s no single ‘best’ method for every project. The right choice depends on what you need! To choose the best printing method for your project, ask yourself:

- What am I making? (A t-shirt, a bag, sportswear?)

- What is the fabric? (Cotton, polyester, blend? Light or dark color?)

- How many do I need? (Just one, a few, or hundreds?)

- What does my design look like? (Simple with few colors, or a detailed photo?)

For example:

- For just one t-shirt with a detailed photo, digital printing (DTG) is often great.

- For 100 shirts with a simple one-color logo, screen printing is usually more cost-effective.

- For breathable sportswear with vibrant, all-over prints, dye sublimation on polyester is a top choice.

4. What can you make with fabric printing?

Fabric printing lets you get creative with so many things! Here are some ideas:

4.1. Clothes

- T-shirts: The most popular! Great for knowing what is fabric print for t-shirts. Use it for band logos, cool sayings, art, photos – anything! This is a big part of garment decoration and custom apparel solutions.

- Hoodies and Sweatshirts: For unique, comfy custom hoodies.

- Dresses and Skirts: For custom patterns.

- Activewear/Sportswear: For printed activewear like team jerseys or yoga pants.

- Baby Onesies: For cute, personalized gifts.

4.2. Bags and hats

- Printed tote bags: Canvas bags are perfect for screen printing or DTG.

- Backpacks: Print on parts or add patches.

- Drawstring Bags: For gym gear or simple carry-alls.

- Custom caps printing: Baseball caps and hats often use heat transfer for logos.

4.3. For your home

- Printed pillow covers and custom home textiles.

- Curtains: With your own patterns.

- Tea Towels and Aprons: Fun for the kitchen.

- Fabric Wall Art: Tapestries or printed canvas.

4.4. Small things

- Fabric Labels: Like printed labels (e.g., heat transfer labels) (a label applied to fabric using heat and pressure, often tagless) or woven labels (a label made by weaving threads together, like on clothing necklines) inside clothes.

- Custom patches: To sew or iron on.

- Printed Ribbons: For gifts or crafts.

- Printed lanyards: For events (often dye sublimation).

- Mousepads: The fabric top is often printed!

5. Quick tips for your fabric printing project

5.1 Think about your fabric

- Know your material: Is it cotton, polyester, a blend? The fabric type matters a lot for how to choose fabric for printing. The weight of paper, for example, is measured in GSM (Grams per Square Meter – a measure of paper weight and thickness); fabric has similar considerations.

- Light or dark color? Printing on dark fabric is different from light fabric.

5.2 Think about your design

- Simple or detailed design? A one-color logo is different from a photo. Check your artwork for fabric printing.

- Size of the print? A large print might feel different depending on the method.

5.3 Think about how many

- One item or many? The best fabric printing quantity and cost of fabric printing method changes. DTG/heat transfer for few; screen printing for many.

5.4 Think about the look and feel

- Desired fabric print feel? Soft (DTG, sublimation) or thicker (screen print, vinyl)?

- Need a very durable print or vibrant print? Some methods last longer or have brighter colors.

6. How knowing fabric printing helps with branding

Understanding fabric printing is also super helpful when branding your products, especially with labels and tags. Packlove knows this well!

6.1 Better choices for your brand

Knowing how your fabric is printed helps you pick brand labels and tags that work best. Example: For soft DTG printed cotton shirts, a Packlove heat transfer label is great – it’s smooth and comfy.

For tough screen-printed canvas bags, a durable Packlove woven label adds a quality touch. To further elevate your brand, consider premium finishes for your other branding materials, like hang tags. At Packlove, we also offer options like embossing or foil stamping for paper goods to create a complete, high-end branding package.

At Packlove, we help you choose labels that complement your fabric and print method, ensuring they look great and feel comfortable.

6.2 Packlove cares about quality

At Packlove, every detail matters. Your fabric print is important, and so are your branding elements. When your label matches your fabric’s quality and print, it shows customers you care. We offer quality clothing labels and expert advice for perfect Packlove branding solutions.

- Need help choosing labels for your printed items? Explore Packlove’s custom label options:

- Contact Packlove for a free chat about your branding needs!

7. Common questions about fabric printing (FAQs)

Here are quick answers to some common questions:

7.1 Which fabric printing lasts the longest?

Dye sublimation on polyester is extremely durable. Good screen prints also last a very long time. Caring for printed clothes properly always helps!

7.2 Can I print on dark clothes?

Yes! Screen printing (with opaque inks), DTG (with a white base layer), and some heat transfers work well on dark fabrics.

7.3 Is fabric printing very expensive?

Cost depends on method, quantity, and design complexity. DTG/heat transfer can be cheap for few items; screen printing is good for many.

7.4 How do I wash printed clothes?

To wash printed t-shirts and other items:

- Turn inside out.

- Wash in cool water with mild soap.

- Avoid harsh soaps/bleach.

- Hang dry or tumble dry low.

- Always check care labels!

Explore more:

Fabric printing is a fun and creative way to bring designs to life on clothes, accessories, and home items. With so many printing methods and fabric types available, understanding the basics can help you choose the right technique for your project or brand.

Whether you’re making a custom t-shirt, designing a tote bag, or exploring fabric art, knowing how fabric printing works gives you more freedom to create with confidence. Now that you’ve got the essentials, it’s time to get creative and start printing your ideas onto something real!