What Is Fabric Weight? A Simple Guide to GSM & Oz

Understanding fabric details can seem tricky. But one basic idea, fabric weight, is easy to grasp. It greatly helps in choosing the right material for anything you make or brand. Knowing a little about this can make a big difference in your product’s quality and feel. This guide will simply explain fabric weight.

1. What is fabric weight and why should you care?

Let’s start with the basics. You’ve likely felt the difference between a light summer shirt and a heavy winter coat. Fabric weight is the key to understanding this difference.

1.1 What is “fabric weight”?

Fabric weight is a simple way to know how heavy a piece of fabric is. It’s not about how much a whole big roll of fabric weighs. Instead, it measures how heavy a standard-sized piece is.

Think of it like this: if you have a square piece of paper and a square piece of cardboard that are the exact same size, the cardboard will feel heavier. Fabric weight is a way to measure that kind of “heaviness” for different fabrics.

This measurement helps compare different fabrics fairly. We can tell if they are light, medium, or heavy for their size. This measurement is a key textile specification, which is simply a detail that describes the fabric.

At Packlove, when we talk about choosing materials for your custom items, like the feel of a woven label, which is made by weaving threads together and often found on clothing necklines, or the sturdiness of a fabric pouch, this idea of ‘weight’ or ‘density’ is something we consider. We want to ensure the final product feels right.

1.2 Why is knowing fabric weight important?

So, why should you care about how heavy a fabric is? Knowing this helps you a lot:

- Choose the best fabric: It helps you pick the perfect fabric for your project. This could be clothes, bags, items for your home, or even choosing the right kind of clothing labels for your brand.

- Feel of the fabric: It changes how the fabric feels when you touch it. Is it soft and light, or firm and strong? This is a key factor in product design.

- How it hangs: It affects how the fabric falls or hangs. Some fabrics flow beautifully, while others keep their shape.

- How long it lasts: Often, heavier fabrics are stronger and can last longer, especially for things that get used a lot. This influences textile quality.

- For brands: If you have a brand, the weight of the fabric in your products matters. Even your labels from Packlove, such as woven labels or heat transfer labels that are applied using heat and pressure, can make your product feel more special and high quality.

2. How we measure fabric weight: The easy way

Now that you know what fabric weight is, let’s see how it’s measured. There are two main ways.

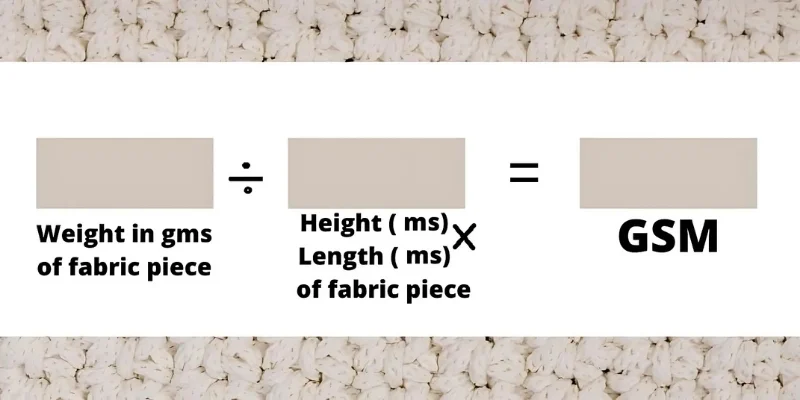

2.1 The two main ways: GSM and oz/sq yd

You’ll usually see fabric weight written in one of two units.

- GSM (Grams per Square Meter): This is the international standard for fabric weight. It simply measures how much a one-meter by one-meter square of fabric weighs in grams. For example, a fabric labeled “180 GSM” means a one-square-meter piece weighs 180 grams.

- oz/sq yd (Ounces per Square Yard): Primarily used in the USA, this system measures how much a one-yard by one-yard square of fabric weighs in ounces. For instance, a “6 oz/sq yd” fabric means a one-square-yard piece weighs 6 ounces.

2.2 Simple rule: Bigger number = heavier fabric

Here’s the most important thing to remember, whether you see GSM or oz/sq yd: A bigger number means a heavier fabric (for that standard size). A smaller number means a lighter fabric. So, a fabric that is 250 GSM is heavier than a fabric that is 150 GSM. And a fabric that is 10 oz/sq yd is heavier than one that is 6 oz/sq yd.

It’s that easy to compare them once you know the number for that specific unit of measure (e.g., GSM, oz/yd²). Just remember, GSM and oz/sq yd are different scales. You can’t directly compare a GSM number to an oz/sq yd number without converting. For example, 1 oz/sq yd is about 33.9 GSM. But usually, you’ll just see one type of measurement listed, so focus on that.

3. Why fabric weight really matters for your fabric

Fabric weight isn’t just a number. It changes many things about the fabric itself.

3.1 How weight changes how fabric looks and feels

Fabric weight influences several key characteristics.

Drape

“Drape” is just a fancy word for how a fabric hangs or flows. Fabric weight is a big reason why fabrics drape differently. Light fabrics (low GSM/oz) usually flow easily and softly. Think of a light scarf dancing in the breeze or a lightweight fabric summer dress that moves with you. They are often airy.

Heavy fabrics (high GSM/oz) are often more structured and hold their shape. Think of a denim jacket made from heavyweight fabric that feels firm or a canvas bag that can stand up on its own. Medium weight fabric options are in between. They often have a nice balance of some flow and some shape.

Durability

Generally, heavier fabrics tend to be stronger and last longer. This is often because they have more fibers, or thicker fibers, packed together. But this isn’t always true! A lightweight fabric that is woven very tightly can be surprisingly strong.

And a heavy fabric that is loosely made might not be very durable. It’s a general idea, not a strict rule. Think about tough work jeans made from heavy denim versus a delicate blouse. The jeans are made to be much more durable.

Durability is super important for many things Packlove helps create. For example, our rubber labels (durable, flexible labels often made from PVC or silicone) are great for outdoor gear because they are very durable. For woven labels on clothes you wear and wash a lot, we aim for materials that will last. This often means choosing a construction that has good density.

Opacity

Opacity simply means how see-through a fabric is. Lighter fabrics are often more sheer or transparent. You might be able to see light or even shapes through them. Heavier fabrics are usually more opaque, meaning you can’t see through them easily.

They block more light. This is usually because heavier fabrics have more material packed into the same space. This is important when choosing fabric for clothes. You probably want opaque fabric for pants. But a slightly sheer top might be nice for summer!

Warmth

Usually, heavier fabrics give more warmth. This is because they are often thicker and can trap more air between their fibers. Trapped air helps keep you warm, like insulation in a house. Think of a thick, heavy wool coat for a cold winter day compared to a light cotton t-shirt for summer. The coat is much warmer! Lighter fabrics are usually better for warm weather. They let air pass through more easily.

3.2 What it’s good for

So, knowing all this, how does it help you pick fabrics? The key is to match the fabric weight to what you want to make or use it for. You wouldn’t use super heavy canvas (great for a strong tote bag) to make a soft, flowy summer dress. It would be too stiff and hot! And you wouldn’t use very thin, see-through chiffon (lovely for scarves) to make work pants that need to be strong.

Choosing the right weight means your project will look, feel, and work much better. This idea of “matching” is also super important for things like your brand’s clothing labels and tags. The label should feel like it belongs on the garment. A big, heavy, stiff label on a soft baby onesie? Probably not a good match! At Packlove, we help you think about this.

Your branding items should feel just right and add to your product’s quality. When you find examples of different fabric weights for textile products, consider how your branding will fit.

4. Fabric weight categories: Light, medium, and heavy

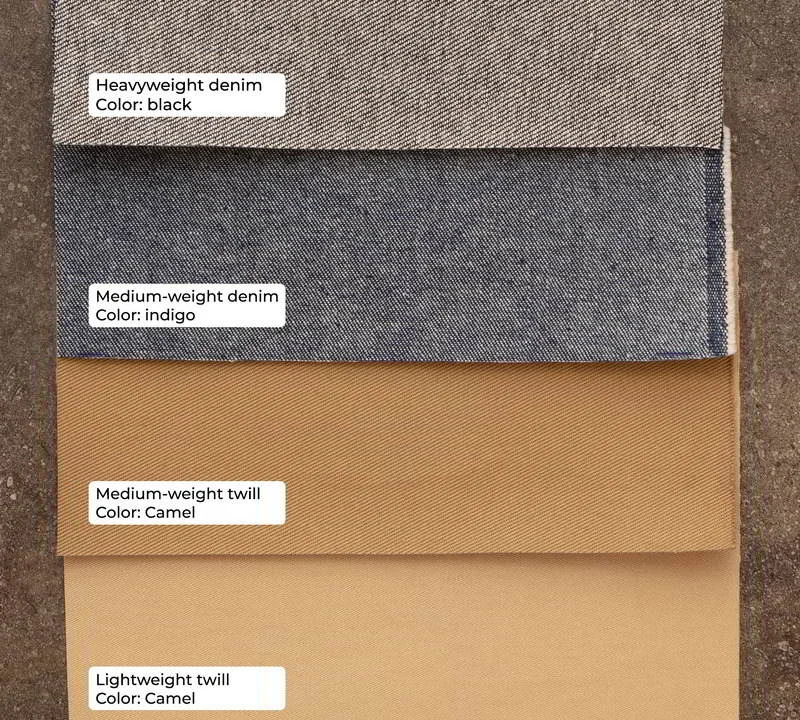

Let’s look at some common fabric groups. This will help you find examples of different fabric weights for textile products.

4.1 Lightweight fabrics

First, lightweight fabrics. These are on the lighter side. You might see them described as typically under 150 GSM (Grams per Square Meter) or around 4.5 oz/sq yd (Ounces per Square Yard). But remember, these are just general guides, not strict rules!

How they feel & look:

- Often sheer (see-through) or semi-sheer

- Feel airy and light

- Flow and drape softly

- Can feel delicate

- Usually dry quickly

Common fabric examples:

- Chiffon

- Organza

- Voile

- Gauze

- Very light cotton lawn

- Some rayons and silks

- Thin linings for clothes

Common uses:

- Summer blouses and shirts

- Flowy dresses and skirts

- Scarves

- Lingerie

- Light curtains

- Linings inside jackets or dresses

4.2 Medium-weight fabrics

Next up: medium-weight fabrics. These are very versatile! These are in the middle, often around 150 to 350 GSM, or about 4.5 to 10 oz/sq yd. This is a very common range for many everyday items.

How they feel & look:

- Have good “body” – not too thin, not too thick

- Usually drape well but can also hold some shape

- Feel comfortable for many uses

- Mostly opaque (not see-through)

Common fabric examples:

- Standard T-shirt cotton (often called jersey knit)

- Quilting cotton

- Poplin (for shirts)

- Most linens

- Flannel

- Fleece

- French terry (for sweatshirts)

Common uses:

- T-shirts and casual shirts

- Everyday dresses and pants

- Children’s clothes

- Pajamas

- Craft projects

- Light jackets

4.3 Heavyweight fabrics

And finally, heavyweight fabrics – the strong ones! These are at the top end of the scale, often over 350 GSM or above 10 oz/sq yd. Some, like for furniture, can be much heavier.

How they feel & look:

- Feel sturdy and very durable

- Often quite structured or stiff, they hold their shape well

- Can be very warm

- Usually very opaque

Common fabric examples:

- Denim (for jeans)

- Canvas (for bags, aprons)

- Corduroy

- Heavy wool (for coats)

- Upholstery fabric (for furniture)

- Heavy duck cloth

Common uses:

- Jeans

- Jackets and coats

- Workwear (like overalls)

- Strong tote bags and backpacks

- Furniture coverings

- Heavy curtains

When branding your products, even small details like labels and tags matter. Fabric weight plays a role here too.

5.1 Why fabric weight matters for your product labels

When you add a brand label to your product, like a woven label, its “weight” or feel should match the fabric of your item. Why?

- Comfort is key: A thick, stiff label on a very soft, light silk blouse can feel scratchy or bulky. It might even make the delicate fabric pucker or hang funny.

- Looks count too: A very thin, flimsy label on a rugged denim jacket might look cheap or out of place. It might also wear out much faster than the jacket itself. The impact of fabric weight on a label’s print detail and feel is noticeable.

- Harmony matters: The goal is for the label to feel like a natural, high-quality part of your product. It should blend in nicely. This is key to matching label weight to garment fabric type.

At Packlove, we help you think about this. For a high-end cashmere sweater, a soft, high-definition damask woven label feels luxurious. For a sporty t-shirt, a smooth, flexible heat transfer label could be perfect because it has no extra bulk.

We know what fabric weight for custom woven labels means for the final touch. Our woven labels are available in various constructions, each providing a different perceived weight and feel.

Even for paper hang tags (tags attached to products, often with string, showing brand/price), the idea of ‘weight’ – meaning the thickness and sturdiness of the cardstock – is important.

- Feels more premium: Thicker, heavier cardstock for hang tags often makes your product feel more special.

- Stays looking good: A sturdier tag is less likely to bend or tear easily.

- Keep it balanced: However, a super-thick tag on a tiny, delicate item might look clumsy.

- Match your product: Think about what kind of product it is. A luxury item might get a thicker tag.

When clients order hang tags from Packlove, we often discuss paper options. For luxury brands, a thicker, maybe even textured, card stock is popular. A sturdy kraft paper hang tag can send an earthy message.

5.3 Packlove’s tip

Here’s a friendly tip from us at Packlove: When you’re designing your custom branding with us – whether it’s woven labels, heat transfer labels, rubber labels, zipper bags (resealable plastic bags), or hang tags – we always love to hear about your main product. What is it made of? What’s its style? Who is it for? This helps with apparel branding.

Our goal isn’t just to print your logo. We want to help you choose materials and styles that really fit. For woven labels, the type of weave (like soft damask for tiny details, or a basic taffeta) can change how the label feels. This is just as important as how it looks!

6. Simple tips for choosing the right fabric weight

Choosing fabric can be easy if you keep a few things in mind.

6.1 Think about what you’re making

First, always ask: What am I making with this fabric? This is a fundamental material selection criteria.

- Clothes? Is it for summer (lighter weights) or winter (heavier)? Does it need to flow (dress) or be sturdy (work pants)?

- Bags? A light shopping tote or a heavy-duty backpack?

- Home items? Soft curtains that drape, or stiff placemats?

6.2 Read product descriptions carefully

When you buy fabric, especially online, read the product description carefully.

- Look for GSM or oz/sq yd numbers.

- Words like ‘lightweight,’ ‘medium-weight,’ ‘heavyweight.’

- Use suggestions like ‘shirting weight’ or ‘bottom-weight.’

6.3 Feel the fabric

The very best way to understand fabric weight is to feel it. If you can, go to a fabric store. Touch different fabrics. If you buy online, many sellers offer swatches (small sample pieces). Getting a swatch first is a great idea.

6.4 Look at similar things you already own

A super easy way to learn is to look at clothes or fabric items you already own and like. Pick up your favorite t-shirt. How does it feel? Now compare it to your jeans. Big difference, right? That’s fabric weight! Doing this helps you get a real feel for what different weights are like.

7. Frequently Asked Questions (FAQs)

Here are some common questions about fabric weight.

7.1 What is a good fabric weight (GSM) for a t-shirt?

For a typical, everyday t-shirt, many people like a medium-weight fabric. This is often around 160 to 200 GSM. If you want a lighter, softer t-shirt, especially for summer, you might look for around 130 to 150 GSM. For a heavier, more premium t-shirt, it could be 220 GSM or even more. It really depends on the style and feel you want! Understanding the t-shirt’s GSM also helps you choose a label with a matching feel.

7.2 Is fabric weight the same as fabric thickness?

They are very closely related, but not exactly the same thing. Usually, a fabric that weighs more (higher GSM) will also be thicker. But not always! You can have a lightweight fabric that is fluffy and seems thick. Or, a fabric made with very fine, dense threads that is thin but quite heavy. So, while they often go together, weight is a more exact measure of how much material there is.

7.3 How does fabric weight affect printing on fabric or labels?

Fabric weight, and also its texture, can affect printing. Very lightweight, sheer, or very textured fabrics can be harder to get a super sharp print directly on them. Smoother, more stable fabrics – often medium to some heavier weights – usually allow for clearer prints. For labels, especially woven labels from Packlove, the amazing detail we can get is more about the weave type (e.g., taffeta, damask) than just the weight.

A damask weave (a weave allowing intricate patterns, often used for high-quality labels) is dense and uses fine threads, allowing tiny details. A taffeta weave (a basic, plain weave often used for labels) is simpler and can feel lighter. For woven labels, the final detail and feel are more influenced by the weave type (like damask or taffeta) than the overall weight.

7.4 Can I usually find fabric weight on clothing care labels?

No, not usually. Clothing care labels tell you:

- What the fabric is made of (e.g., 100% Cotton).

- How to wash and care for the garment.

Fabric weight (like GSM) is information you usually find when buying the fabric itself.

7.5 If I want custom woven labels from Packlove, how do I choose the right ‘weight’ or feel?

That’s a great question! The easiest way is to talk to us at Packlove! When you want woven labels, tell us about your product:

- What is its fabric (cotton, silk, denim)?

- What’s its style (baby clothes, outerwear)?

- What overall feel do you want?

We guide you based on the weave structure (like Taffeta, Satin, or Damask).

- Damask woven labels are soft, smooth, luxurious, and allow amazing detail. They have a nice ‘body’ or perceived weight.

- Taffeta woven labels can feel lighter and flatter, great for simpler designs.

- Satin woven labels (labels with a smooth, glossy surface) have a beautiful sheen.

Read more:

So, fabric weight isn’t so tricky after all! It just tells you if a fabric is light, medium, or heavy for a standard size. We measure it using GSM or oz/sq yd – and remember, a bigger number means heavier fabric.

Most importantly, knowing about fabric weight helps you choose the right materials for all your projects. This includes everything from making clothes to picking the best custom labels and tags for your brand with Packlove. Making smart choices about fabric weight leads to products that look better, feel better, and often last longer.

If you’re ready to create amazing branded items like woven labels, heat transfer labels, rubber labels, zipper bags, poly mailers (lightweight, durable plastic bags for shipping), or other custom packaging, Packlove is here to help. Explore Packlove’s wide range of custom branding solutions today!