What Is Non-Woven Fabric? Simple Guide: Properties And Uses

In our everyday lives, we encounter and use countless products often without realizing they’re made from a special material: non-woven fabric. From the familiar medical face masks and convenient reusable shopping bags to versatile cleaning wipes and even linings in clothing and construction.

So, what exactly is non-woven fabric? What makes it so different and widely applicable compared to traditional woven or knitted textiles? This ‘Simple Guide: Properties & Uses’ will explore these questions, unveiling the fascinating world of non-woven fabric. Let’s dive in!

1. What is non-woven fabric?

1.1 What does “non-woven” mean?

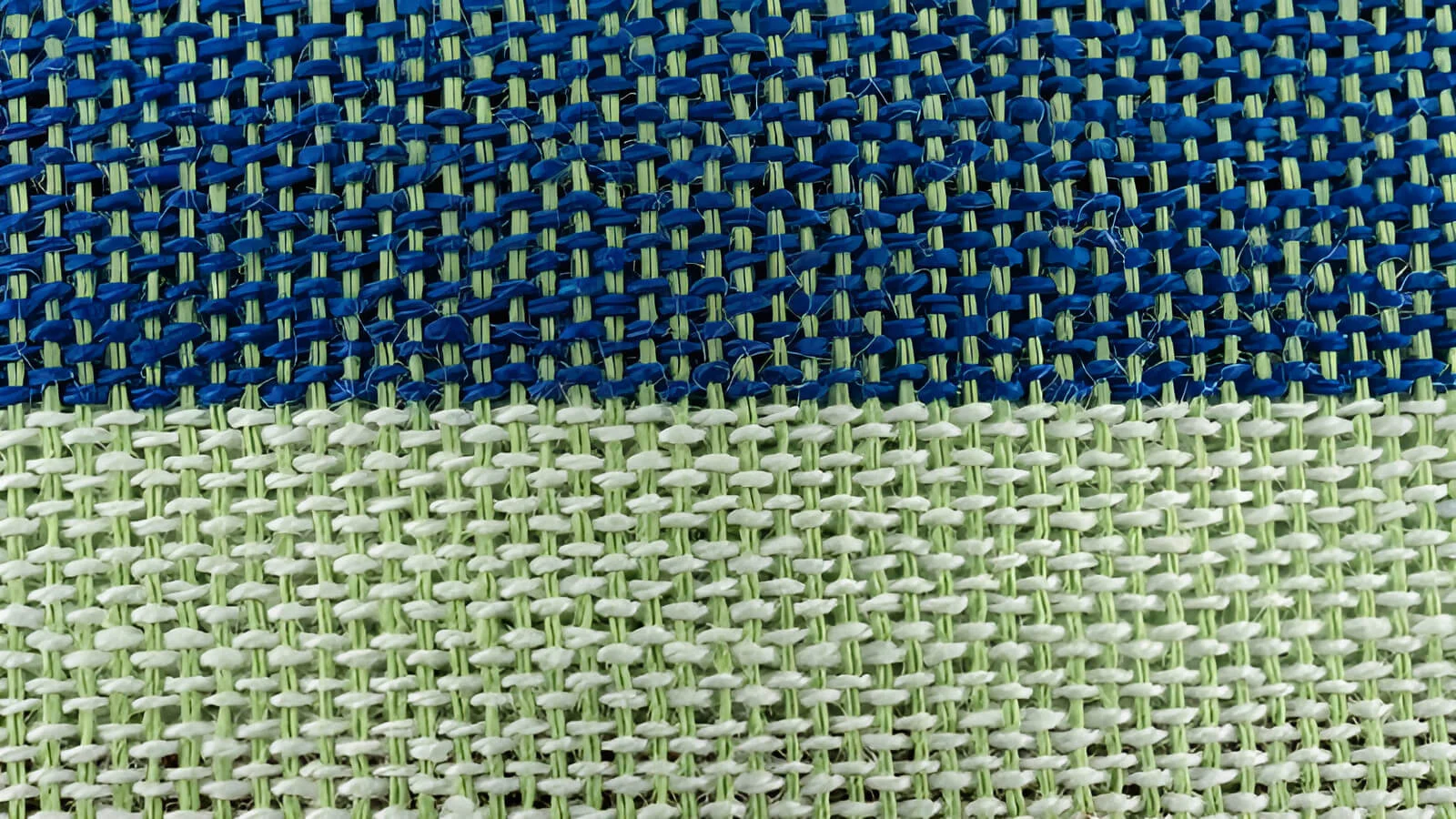

Non-woven fabric is a special kind of textile material. The name tells you how it’s made: the fibers are not woven together like your jeans or t-shirts. Think about normal clothes: woven fabrics (like denim) have threads going over and under each other in a grid. Knitted fabrics (like sweaters) are made of loops of yarn.

Non-woven fabric is different. It’s made from fibers that are stuck together. Imagine a flat sheet made by pressing or heating tiny fibers until they join. It’s a bit like how felt is made, or even how paper is made from wood fibers, but non-woven fabric often uses plastic fibers. It’s basically a bonded fabric (meaning the fibers are joined together) instead of woven or knitted.

1.2 An easy way to picture it

Imagine taking a handful of short fibers, spreading them out flat like a messy web, and then finding a way to make them stick together into one sheet. That sheet is a non-woven fabric. It’s not made from threads crossing over each other.

1.3 Why learn about this fabric?

You probably use things made from non-woven fabric every day without knowing it! Things like shopping bags, wipes, and even parts of furniture use it. Learning about non-woven textile materials helps you understand what products are made of. This can help you choose better products, like picking a strong reusable bag.

2. Non-woven vs. other fabrics: what’s the big difference?

Let’s quickly compare non-woven fabric to the two main types of fabric you usually find in clothes:

2.1 Woven fabric

- Made by weaving threads over and under each other, like a basket.

- Examples: jeans, button-down shirts, bed sheets.

- Often feels structured and strong. Durability can be very high.

2.2 Knitted fabric

- Made by looping yarn together, like knitting a sweater.

- Examples: t-shirts, sweaters, socks.

- Often stretchy and soft.

2.3 Non-woven fabric

- Made by bonding fibers together using heat, chemicals, or needles. No weaving or knitting involved. This is the main difference.

- Examples: reusable shopping bags, face masks, wipes.

- Texture can vary a lot – some are soft, some are stiff.

3. How is non-woven fabric made?

Making non-woven fabric involves a few simple steps:

3.1 Step 1: Get the fibers

First, you need the basic building blocks – fibers. These are often tiny strands of plastic. The most common plastic fiber used is Polypropylene (PP). Sometimes other fibers like polyester (PET) or even natural ones like cotton or viscose are used or mixed in, but PP is very popular, especially for things like reusable bags. The fiber composition affects how the final fabric feels and works.

3.2 Step 2: Make a flat sheet

Next, these loose fibers are laid out flat to form a sheet or web. Imagine blowing the fibers onto a surface or combing them flat.

3.3 Step 3: Stick them together!

This is where the magic happens – joining the fibers without weaving or knitting. There are a few main bonding methods:

- Heat: This is very common for non-woven bags. The web of fibers passes through hot rollers. The heat melts the polypropylene fibers slightly, making them fuse together. Spunbond (a specific, efficient manufacturing technology where fibers are spun out and then immediately bonded with heat) is widely used.

- Glue: Sometimes, a special glue is used to hold the fibers together.

- Needles: Tiny needles punch through the fiber web over and over, tangling the fibers together physically, like making felt.

4. What’s so great about non-woven fabric?

Non-woven fabric has some cool properties that make it useful:

4.1 Can be water-resistant

Many non-woven fabrics, especially those made from Polypropylene (PP), don’t soak up water easily. They can resist spills or light rain (but aren’t usually fully waterproof).

4.2 Can be breathable

Some types of non-woven fabric allow air to pass through. This property is called breathability or porosity, and it’s important for things like masks or medical gowns. Note: a fabric might be water-resistant or breathable, often not both strongly.

4.3 Usually costs less

The manufacturing process is often faster and cheaper than weaving or knitting, making non-woven fabric a cost-effective choice for many items.

4.4 Good for printing

The surface is usually smooth and takes ink well. This makes it great for printing logos or designs, like on a custom non-woven bag for branding.

4.5 Lots of choices

Non-woven fabric comes in many colors and thicknesses. Thickness is often measured by basis weight (gsm) (grams per square meter – a measure of paper weight and thickness). A higher gsm means a thicker, heavier, and often stronger fabric.

4.6 Versatile

Because you can change the fibers and bonding methods, non-woven fabric can be made suitable for many different jobs.

5. Where do you see non-woven fabric in your daily life?

You probably use non-woven fabrics more often than you realize! Here are some common examples:

5.1 Reusable shopping bags

This is a very common use. Many of those colorful bags you get at the grocery store are made from spunbond polypropylene non-woven fabric. They are strong, light, reusable, and easy to print on, making them great reusable bag materials and non-woven tote bags.

5.2 Packaging

You might find it used as simple packaging materials. Think of dust bags for shoes or handbags, protective wraps for electronics inside a box, or simple pouches.

5.3 Cleaning wipes

Both dry dusting wipes and wet wipes often use non-woven material because it can absorb liquids and is strong enough not to fall apart easily. These are common disposable product components.

5.4 In your home

Look under your sofa or chairs – that thin black fabric covering the bottom is often non-woven. It’s also used inside mattresses, as carpet backing, or as interfacing (stiffening material) inside shirt collars or cuffs.

5.5 Medical and hygiene

Non-woven fabrics are crucial here. Face masks, surgical gowns, caps, shoe covers, bandages, and parts of diapers and sanitary pads are often made from specialized non-woven materials.

5.6 Packlove contextual example

Think about creating a nice experience when someone opens a product. A simple non-woven pouch inside a gift box can protect individual items and make the package feel more special. These properties also make non-woven fabric excellent for promotional tote bags handed out at trade shows or events – they carry the brand effectively.

6. Is non-woven fabric earth-friendly?

This is an important question with a few parts:

6.1 Reusability is key

The biggest environmental win for non-woven bags is that they replace hundreds of single-use plastic bags. Using your non-woven bag many, many times is the best thing you can do. This makes them sustainable alternatives to plastic bags when used correctly.

6.2 Recycling

Common non-woven fabric made from Polypropylene (PP) is technically recyclable. However, not all local recycling centers accept non-woven bags. Check your local recycling rules. Look for a recycling symbol on the bag’s tag if it has one.

6.3 Biodegradability

Most common non-woven fabrics, like those made from Polypropylene (PP), are plastics and do not biodegrade. They won’t break down naturally in the environment if they become litter. There are specialty non-woven fabrics made from plant-based materials like PLA (Polylactic Acid) non-woven (a biodegradable plastic derived from renewable resources like corn starch), which can biodegrade under specific industrial composting conditions, but these are less common for standard reusable bags.

6.4 The bigger picture

The lifecycle of non-woven products matters. Reusing them as much as possible is the most eco-friendly action. When they wear out, check if they can be recycled locally. Some companies also offer non-woven bags made from recycled materials, like rPET non-woven (made from recycled plastic bottles), which is another step towards sustainability.

7. Could non-woven fabric be useful for you?

Based on what we’ve learned, non-woven fabric could be a great choice if you:

- Need affordable promotional tote bags for your business event or as giveaways.

- Want simple, protective custom branded packaging, like dust bags or inner pouches for your products.

- Are looking for a material that is generally strong, lightweight, often water-resistant, reusable (especially for bags), and easy to print on for branding.

Understanding materials like non-woven helps you choose the right options for your needs, whether it’s for packaging your products or promoting your brand. Exploring different materials is key to finding the perfect fit. You can explore packaging options at Packlove’s blog or see examples of custom non-woven bags.

8. Quick questions, simple answers (FAQs)

8.1 Is non-woven fabric a type of plastic?

Often, yes. The most common type, non-woven polypropylene (PP), is made from plastic fibers. But it’s processed into a fabric-like sheet, not a hard plastic item.

8.2 How strong is non-woven fabric?

It’s surprisingly strong for how light it feels. Perfect for everyday tasks like carrying groceries in a reusable bag. Strength varies with the thickness (gsm).

8.3 Can I wash non-woven bags?

Usually, yes, but gently. Hand wash in cool water with mild soap and let it air dry. Avoid machine washing or drying, as heat can damage it. Check the bag’s tag for specific care instructions if available.

8.4 What is “non-woven polypropylene (PP)”?

It’s simply non-woven fabric made specifically from polypropylene plastic fibers. It’s one of the most common and affordable types, often used for those colorful reusable shopping bags.

8.5 Why choose non-woven bags over cotton bags?

It depends on your needs. Non-woven bags are generally: cheaper, lighter, dry faster, and more water-resistant. Cotton bags are: made from a natural fiber, very strong and durable, breathable, but also heavier, absorb water easily, and usually cost more.

8.6 Are all non-woven fabrics the same?

Definitely not! They can be made from different fibers (PP, PET, rPET non-woven, PLA, etc.), come in various thicknesses (gsm), and use different bonding methods. This creates a wide range of non-woven fabrics for different uses.

Explore more:

In essence, non-woven fabrics represent a fascinating and highly versatile category of textiles, distinguished by their unique manufacturing process that bypasses traditional weaving or knitting. As this guide has demonstrated, their engineered nature allows for a remarkable range of properties – from absorbency and strength to breathability and disposability – which can be tailored to specific needs.

Understanding the basics of non-woven fabrics illuminates the innovative engineering behind many products we rely on daily. They are a testament to material science’s ability to create cost-effective, functional, and often sustainable solutions for a myriad of modern challenges. As technology continues to evolve, the world of non-woven fabrics will undoubtedly expand further, continuing to shape industries and improve our lives in ways both big and small.