What Is Plain Weave? Fabric Basics And Woven Label Uses Explained

Step into the world of textiles, and you’ll quickly encounter a fundamental building block, a true cornerstone of fabric construction: the plain weave. It’s the simplest, oldest, and arguably most common of all weave structures, yet its unassuming nature belies its incredible versatility and widespread use. From the crisp cotton shirt you might be wearing to the sturdy canvas of a tote bag, the chances are high that plain weave is playing a leading role.

This guide will unravel the essentials of plain weave, exploring its defining characteristics, its role in the broader world of fabrics, and specifically how this foundational weave lends itself perfectly to the intricate world of woven labels that brand and inform our garments and goods.

1. Introduction: What is plain weave? Your easy guide

1.1 What is plain weave in simple words?

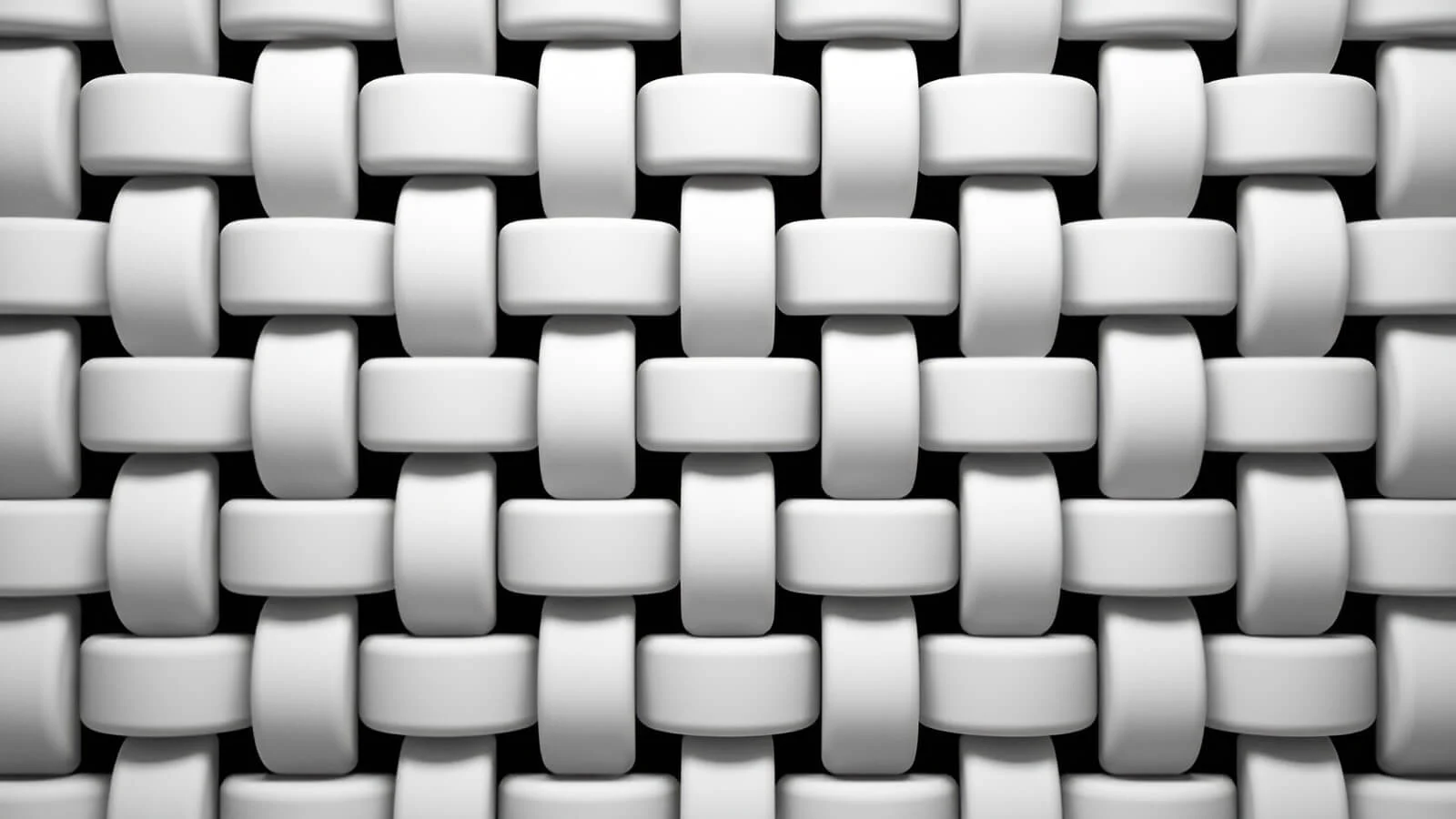

Plain weave is the most basic way to make fabric. Think of a simple checkerboard pattern. In a plain weave, one thread goes over the next thread, then under the one after that, then over, then under. This simple one-over-one-under weave is repeated across the entire fabric.

The threads running lengthwise are called warp threads, and the threads running crosswise are called weft threads. The way these warp and weft threads interlace (cross over and under each other) creates the fabric’s textile structure. Plain weave is the simplest of these structures, often called a basic weave or simple weave.

1.2 Why learn about plain weave?

Understanding plain weave is useful because it’s incredibly common. You’ll find it in many everyday items like clothing, home goods, and bags. Learning about this simple fabric weave helps you make better choices when buying fabric items.

More importantly for your brand, this knowledge helps when ordering custom products like woven labels. Knowing fabric basics like plain weave means you can better discuss your needs with suppliers, including Packlove. This leads to understanding textile terms for branding and getting the product that’s right for you.

1.3 What you’ll learn in this guide

Packlove’s guide to plain weave will cover:

- How plain weave is made.

- Its key fabric features and feel.

- Common examples of plain weave fabrics and items.

- The advantages and disadvantages of plain weave.

- How plain weave is used in woven labels, a popular branding tool.

2. How is plain weave made? The weaving basics

2.1 Meet the threads: Warp and weft

Two sets of threads are needed to create woven fabric:

- Warp threads: These yarns run up and down on a weaving machine called a loom. Warp threads are held tight under tension.

- Weft threads: These yarns run from side to side. The weft thread is woven through the warp threads.

Think of warp threads as running North to South, and weft threads as running East to West.

2.2 The simple “over-under” pattern

The magic of plain weave happens in the simple interlacing process. One single weft thread passes over one warp thread, then under the next warp thread. This “over one, under one” pattern repeats across the width of the fabric.

The next weft thread then does the exact opposite. If the first weft thread went over warp thread #1 and under warp thread #2, the second weft thread will go under warp thread #1 and over warp thread #2. This consistent alternating creates the simple criss-cross pattern characteristic of plain weave.

This yarn interlacing forms the basic criss-cross pattern characteristic of plain weave.

2.3 What a loom does

A loom is the machine used in textile manufacturing to make woven fabric. Its main jobs are:

- To hold the warp threads straight and tight.

- To lift selected warp threads at the right moment, creating a space (called a shed) for the weft thread to pass through easily. This mechanical action allows the weaving process to happen efficiently, creating the interlaced fabric.

3. Key features and feel of plain weave fabrics

3.1 Strong and durable

Plain weave fabrics are generally strong and durable. This is because the warp and weft threads interlace very frequently. Each point where threads cross locks them together tightly, preventing them from shifting easily. This high number of interlacing points contributes to good fabric durability, making it a strong weave.

This strong and simple characteristic makes it suitable for items that need to withstand wear and washing, like labels.

3.2 Smooth, flat surface

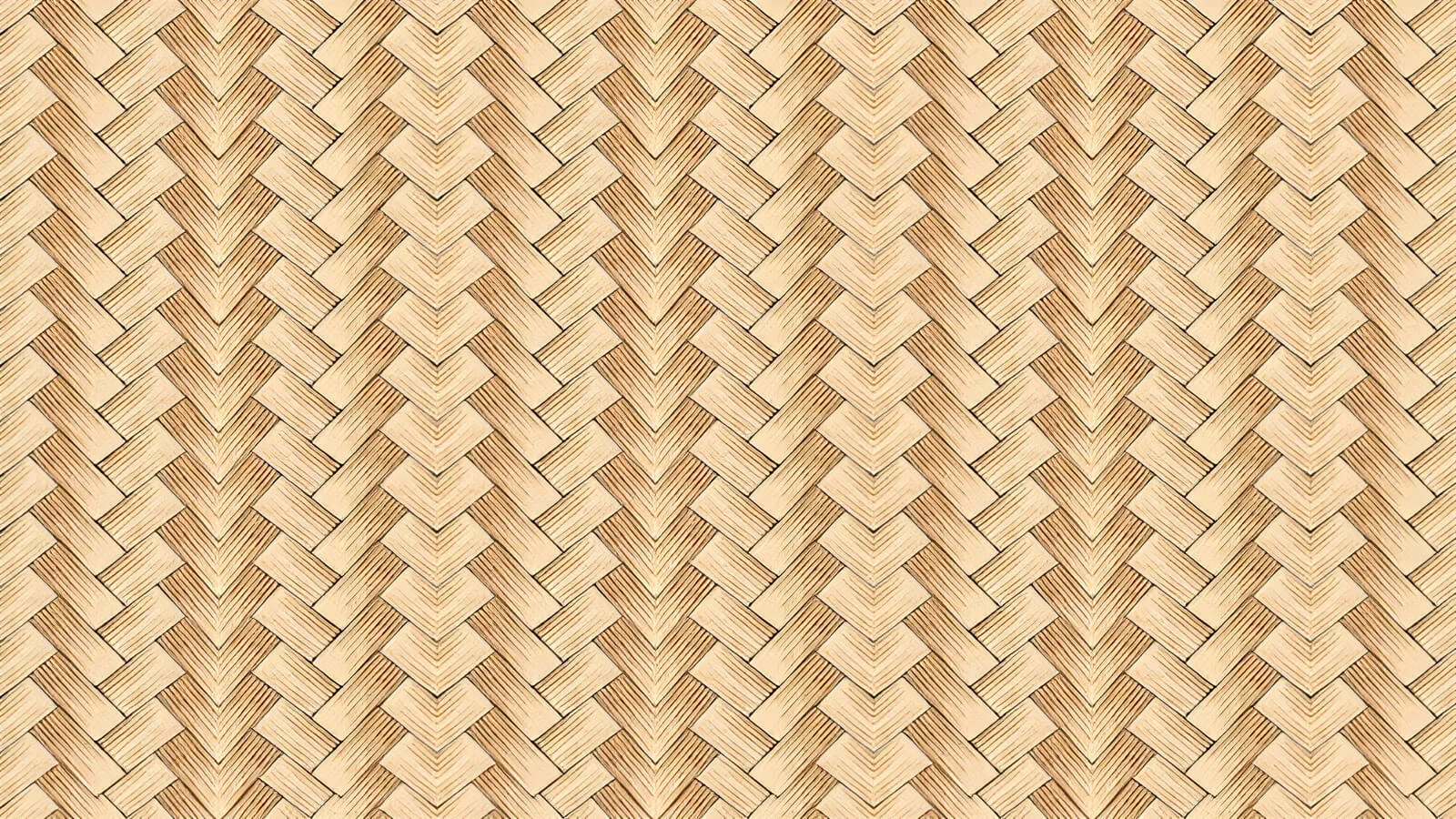

Most plain weave fabrics have a flat and relatively smooth surface. This is different from other weaves; for example, twill weave has diagonal lines, and satin weave has long “floats” of thread that give it shine.

The flat surface of plain weave makes it a good for printing designs or text. The resulting texture can vary slightly based on the thickness of the yarns used, but it typically lacks a prominent raised texture.

3.3 Looks the same on both sides

In a standard or balanced plain weave, the front and back of the fabric look identical. This is due to the simple, symmetrical fabric structure. This makes the fabric reversible fabric. Sometimes, if different colored warp and weft threads are used, the sides might look different in color, but the basic weave structure remains the same.

3.4 Can wrinkle easily

One common characteristic of plain weave fabrics is that they can be prone to wrinkles. The tight fabric structure and frequent interlacing mean the fabric doesn’t have much ‘give’ or elasticity.

This makes it more likely to hold creasing and wrinkles compared to some other weave structures or knitted fabrics. The tendency to wrinkle also depends on the fiber used. These are important fabric properties to consider.

3.5 Versatile – used for many things

Plain weave is incredibly versatile. It can be made using almost any yarn type – including cotton, polyester, silk, linen, and wool. It can also be woven with different fabric density. This means it can range from very loose and airy (like cheesecloth or chiffon) to extremely dense and heavy.

This wide range of possible fabric weight and texture makes plain weave a versatile fabric suitable for countless applications.

3.6 Breathability

The breathability of a plain weave fabric is not fixed; it depends a lot on the fabric density and the type of fiber used. For example, a loosely woven plain weave made from cotton (like muslin) can be very breathable, perfect for warm weather.

However, a very tightly woven plain weave, especially if made from synthetic fibers like polyester, might be much less breathable. These are important fabric properties to note.

4. Common examples of plain weave fabrics and items

4.1 Everyday fabrics

You encounter plain weave fabrics more often than you might think. Here are some common examples:

Cotton-based (using cotton thread):

- Muslin: A lightweight, simply woven cotton fabric.

- Percale: A crisp, smooth plain weave often used for bedsheets.

- Canvas: A heavy, very durable plain weave used for bags, tents, and art.

- Broadcloth: A dense, smooth plain weave often used for shirts.

Linen: Fabric made from the flax plant, often plain woven and popular for summer clothing.

Polyester (using polyester yarn): Many basic polyester fabrics for clothing and home goods use a plain weave.

Lightweight/Sheer:

- Chiffon: A very lightweight, sheer plain weave, often made from silk or synthetic fibers.

- Organza: A crisp, sheer plain weave, stiffer than chiffon.

Crisp/Specific:

- Taffeta is a key example of plain weave. It is known for being crisp, smooth, and often having a slight sheen. It’s tightly woven. This crispness and smoothness make it excellent for certain types of labels, which we call taffeta labels.

4.2 Common items made with plain weave

Because plain weave is so versatile, it’s used to make a huge variety of items:

- Many button-down shirts and blouses.

- Bed sheets.

- Simple cotton tote bags.

- Fabric linings inside jackets, bags, and other items.

- Artist’s canvas for painting.

- Some types of basic T-shirts (though many T-shirts are knitted, some woven ones use plain weave).

5. Why choose plain weave? Advantages and disadvantages

5.1 Advantages

Plain weave offers several benefits:

- Strength and Durability: The frequent interlacing of threads makes it a strong weave and a durable fabric for its weight.

- Relatively Low Cost to Produce: The simple textile manufacturing process for plain weave is generally less complex and faster than for other weaves, making it a low cost fabric option.

- Good Surface for Printing: Its usually flat and stable surface makes it good for printing designs and text clearly.

- Highly Versatile: As we’ve seen, it can be made from many different fibers and in various weights and densities, making it a very versatile fabric.

- Easy to Sew: It generally doesn’t stretch or distort much, making it easier to sew than some other fabric types.

- Advantages of plain weave for labels: For labels, its durability ensures it lasts through washes, it’s cost-effective for large runs, and it provides a good base for simple, clear designs. This is especially true for taffeta labels.

5.2 Disadvantages

However, plain weave also has some drawbacks:

- Prone to Wrinkling: Its tight structure means it can hold creases and wrinkles easily.

- Less Drape than other weaves: It can sometimes feel stiffer and have less fabric drape (how it hangs) compared to weaves like satin or some twills. This results in more fabric stiffness.

- Can Tear More Easily Along the Straight Grain: If snagged, it might tear more readily along the line of the warp or weft threads compared to more complex weaves that distribute stress better.

- Can Feel Basic or Less Luxurious: Compared to more decorative weaves like satin or damask, plain weave can sometimes look and feel more basic, which is a factor in weave comparison, especially for high-end branding labels.

6. Plain weave in product branding: Focus on woven labels

6.1 What are woven labels?

A woven label is a type of label where the design, such as a logo or text, is created by weaving different colored threads directly into the fabric itself. This is different from printed labels, where ink is applied to the surface of a pre-made material.

The process of creating these is known as woven label production. There are different woven label types based on the weave used, detail, and quality. Knowing how woven labels are manufactured helps in choosing the right one.

6.2 Why plain weave is used for woven labels

Plain weave is a popular choice for woven labels, most commonly in the form of taffeta labels, for several reasons:

- Cost-Effectiveness: The simple plain weave is generally faster and cheaper to produce than more complex weaves. This makes taffeta labels an economical option, especially for large quantities or when working with a tighter budget.

- Clarity for Basic Designs: Plain weave provides good definition for simple text (like care instructions or size information) and blocky or less intricate logos. These are key plain weave characteristics for custom labels.

- Durability: The inherent fabric durability of plain weave means these labels can withstand numerous washes and general wear and tear, which is crucial for apparel. So, what is plain weave in fabric labels? It’s often taffeta, a crisp, sturdy, and economical plain weave.

- Is plain weave good for woven brand tags? Yes, for many applications. Its strength and cost-effectiveness make it ideal for functional labels or simple branding.

6.3 When plain weave labels are a good choice

At Packlove, we help brands choose the right label for their needs. We often recommend plain weave taffeta labels for:

- Care and content labels (e.g., “100% Cotton, Wash Cold”).

- Size tags.

- Simple brand logos where extremely fine detail is not the top priority.

- Projects needing a durable label on a tighter budget.

- Internal branding or secondary labels.

Choosing materials for woven labels is an important step. Our experience shows that taffeta is excellent when durability and clear, simple text or basic logos are key, especially for wash care instructions or budget-conscious branding for custom labels.

6.4 Comparing with other weaves for labels

While plain weave (taffeta) is a great all-rounder, it’s good to know about other basic weave types (twill, satin) often used for labels. For example:

- Damask labels: Use a finer weave that allows for much greater detail in logos and text, and often have a softer feel. They are generally more expensive than taffeta.

- Satin labels: Offer a very smooth, shiny surface and a soft feel, often chosen for a more luxurious look. They are also typically more expensive.

To choose the right custom tag for your brand, it’s helpful to compare plain weave with other options available on Packlove. Taffeta labels serve as the sturdy, economical baseline, excellent for many applications. If your design is highly detailed or you need a softer, more premium feel, then damask or satin might be better options.

7. Frequently asked questions about plain weave

7.1 Is plain weave strong?

Yes, plain weave is generally quite strong and durable for its weight. The frequent interlacing of warp and weft threads creates a tight, stable structure, making it a strong weave.

7.2 What does plain weave feel like?

The fabric feel of plain weave is typically smooth and flat. However, the exact feel can vary depending on the type of yarn used and how tightly it’s woven. It can range from soft and flexible to crisp or even stiff.

7.3 Is cotton always plain weave?

No, cotton is a fiber, often used as cotton thread. While cotton can be made into many plain weave fabrics (like percale, muslin, and canvas), it can also be woven into other patterns or even knitted.

7.4 Is plain weave good for clothing labels?

Yes, plain weave is an excellent choice for many types of clothing labels, especially taffeta labels. They are durable enough to withstand washing, can clearly display simple text and logos (ideal for care instructions or basic branding), and are cost-effective.

This helps you know if plain weave is suitable for specific label needs. For very detailed or intricate logos, or if a softer feel is desired, other weaves like damask might be considered.

Explore more:

To sum up, plain weave is the simplest “over-under” weave pattern or simple weave. It creates strong, versatile fabrics that are found everywhere. This includes its important role in producing durable and cost-effective taffeta labels for branding.

Knowing about this basic simple textile structure empowers you to choose the right materials, whether for your personal projects or for your brand’s labels and packaging solutions through Packlove. Need help with your artwork or choosing the right label? Our design team at Packlove is here to assist!