What Is Thread Count? Simple Guide Fabric And Woven Labels

Thread count is a term you often hear with fabrics, but it can sometimes sound a bit complicated. Knowing about it can help you choose good quality items, from your bed sheets to the custom woven labels that make your brand stand out.

This guide from Packlove will make “thread count” easy to understand. We’ll show you what it means for everyday fabrics and, most importantly, how a similar idea called “weave density” helps create detailed, soft, and durable woven labels for your products.

1. What is thread count? A simple guide

1.1. What are we talking about?

Many words used for fabrics can seem technical, and “thread count” is one of them. Understanding fabric terms like this can help you pick better quality clothes, home textiles, and even custom branding items like the woven labels businesses use. This guide aims to simplify the concept of thread count and explain why it’s useful information.

1.2. Defining “thread count” in simple terms

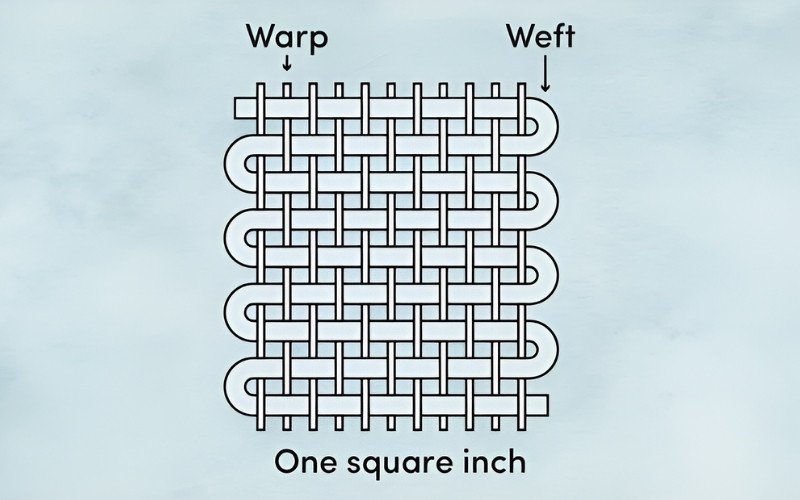

Thread count is simply the total number of threads woven into one square inch of fabric. You find this number by counting all the threads running lengthwise, called warp threads, and all the threads running widthwise, called weft threads, within that single square inch.

Think of it like pixels in a picture: more threads packed into a small space often mean the fabric is finer or can show more detail. It’s about how tightly those threads are packed together.

1.3. Why knowing about thread count can be helpful

A fabric’s feel and durability often depend on its thread count. It affects how soft a fabric feels, how strong and durable it is, and even its overall appearance. This is very useful when choosing fabrics for clothes, home items, and especially for custom woven labels, where clear branding is key.

2. How is thread count actually calculated?

2.1. Meet the threads

All woven fabric, including the material for your labels, is made from two sets of threads: warp and weft.

- Warp threads: These are the threads that run up and down, along the length of the fabric. They are held tight on a loom (a machine used for weaving fabric) when the fabric is being made.

- Weft threads: These are the threads that are woven from side to side, going over and under the warp threads.

These two sets of threads interlock to create the structure of the woven fabric.

2.2. The square inch rule

To measure thread count, people use a standard area: one square inch of fabric. The process is straightforward:

- Count all the warp threads within that one square inch.

- Count all the weft threads within that same one square inch.

- Add these two numbers together. The total is the thread count.

For example:

- If there are 100 warp threads in one square inch,

- And there are 100 weft threads in that same square inch,

- The thread count is 100 + 100 = 200.

- This is often written as 200 TC.

3. Why does thread count matter for general fabrics?

3.1. Softness and smoothness

Generally, fabrics with a higher thread count tend to feel softer and smoother. This is because to fit more threads into a small space, the threads themselves usually need to be finer (thinner). Many fine threads packed closely together create a denser surface that feels gentle against the skin. Think about really soft bed sheets – they often have a higher thread count.

3.2. Strength and durability

A higher thread count can also contribute to a fabric’s strength and how long it lasts. When more threads are packed tightly together, they create a more solid and robust structure. This makes the fabric harder to tear and more resistant to wear and tear from daily use and washing. So, items made from these fabrics often last longer.

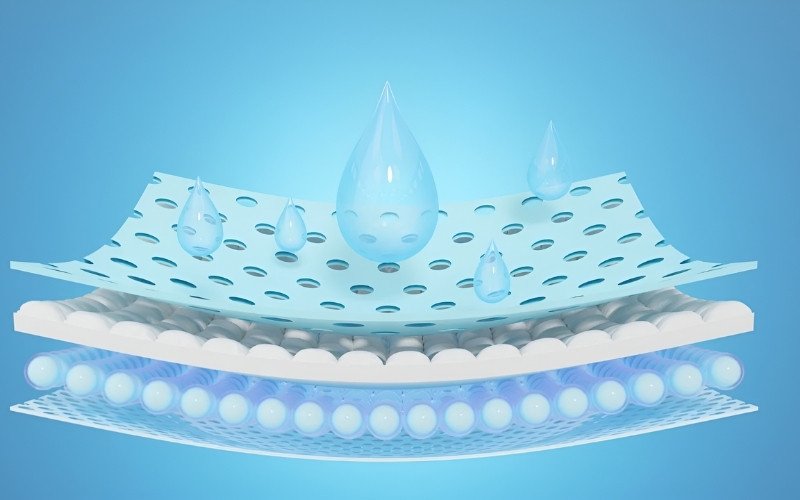

3.3. Breathability

Breathability (how well air passes through a fabric) is important for comfort, especially in clothing. While higher thread counts are often good, if a fabric has an extremely high thread count, it might sometimes be less breathable. This can happen if the threads are packed too tightly, especially if the threads are not very fine. For good breathability, it’s about finding the right balance.

4. Common myths and truths about thread count

4.1. Higher thread count always means better quality

Many people believe that a higher thread count automatically means better fabric quality. This is a common myth. While thread count can be an indicator of quality, it’s not the only factor. For example, a fabric could have a very high thread count, but if it’s made from poor-quality, weak threads, the fabric itself won’t be good.

4.2. Yarn quality is key

The quality of the yarn (the threads themselves) is often more critical than just the count. Several things make yarn good quality:

Fiber type: The raw material used to make the thread is very important. For instance, long-staple cotton (cotton with longer fibers) makes soft, strong threads ideal for bed sheets. For durable and detailed woven labels, fine polyester yarn (a strong, synthetic thread) is excellent because it’s strong, can be made very fine, holds color well, and contributes to a soft feel.

Ply: This refers to the number of smaller strands twisted together to make a single yarn.

- Single-ply yarns (yarns made from one strand): Good quality single-ply yarns are often strong and fine, contributing to a smooth, durable fabric.

- Multi-ply yarns (yarns made by twisting two or more finer strands together): These can be used to make weaker, shorter fibers seem stronger or thicker. Sometimes, this is a way to make the fabric seem higher quality than it is.

4.3. How numbers can be inflated?

Sometimes, manufacturers might inflate thread counts. A common way this is done is by counting each individual strand within a multi-ply yarn. For example, if a fabric uses 2-ply yarns (where each yarn is made of two strands twisted together), and there are 100 of these 2-ply warp yarns and 100 2-ply weft yarns in a square inch, some might advertise it as a 400 TC (100×2 + 100×2).

However, a fabric made with 200 good quality single-ply yarns could actually be superior. A very high number doesn’t always mean it’s the best, especially if achieved this way.

5. Thread count and your woven labels

5.1. Is “thread count” the exact term for woven labels?

When we discuss woven labels, like those on clothing, the concept of how many threads are packed into the material is crucial. While you might hear “thread count,” in the label industry, experts more often use terms like “weave density” or refer to specific weave types such as Damask (a weave known for high detail and softness) or Taffeta (a sturdy, basic weave). The fundamental idea is the same: how tightly threads are packed in an area.

5.2. How thread density affects woven label quality

5.2.1. Detail and clarity in your design

Higher thread density in a woven label means more threads are woven per square inch, typically using finer threads. This offers significant benefits for your design:

- Sharper details: It allows for clear, precise details, even for intricate lines or small parts of logos.

- Clear small text: Even very small letters for brand names or care instructions can be woven legibly.

Think of it like a high-resolution picture: more pixels mean a sharper image; more threads mean a sharper design.

5.2.2. Softness and feel of the label

Labels with finer threads and higher weave density are usually much softer. For example, Damask woven labels are renowned for their high density and use of fine threads, making them very soft to the touch.

This is important for comfort, especially if the label will be in contact with skin, such as on t-shirts, baby clothes, or lingerie. This softness is a key property of a quality woven label.

5.2.3. Durability and longevity

A dense weave, with tightly packed threads, generally makes the label stronger. This brings several advantages:

- It resists fraying at the edges.

- It’s hard-wearing, meaning it can withstand numerous washes and daily wear.

The result is that your branding looks good for longer. The durability of a woven label is influenced by its weave density and textile finish.

5.3. Comparing Packlove’s woven label types

5.3.1. Damask woven labels

- Characteristics: Damask woven labels from Packlove boast the highest thread density. We use very fine threads woven closely together.

- Results: This achieves the best detail, sharpest images, and vibrant colors. Damask labels are also very soft, smooth, and have a luxurious feel, making them a top-quality choice.

- When to choose Damask: Ideal for complex logos, small text, designs with subtle color gradients, or when you want a high-end look.

5.3.2. Taffeta woven labels

- Characteristics: Taffeta woven labels from Packlove offer a good, standard weave density. They are durable and provide clear results for many designs. Taffeta is also more budget-friendly than Damask.

- Results: These labels are great for simpler logos, bold text, and care labels. They provide a professional look.

- When to choose Taffeta: A smart choice for less complex designs, when budget is a key consideration, for care labels, or for general branding where extreme detail isn’t the primary focus.

5.3.3. Other weave options

Packlove may also offer other weave types, such as satin woven labels. These are known for their shiny, smooth, and lustrous surface, giving a glossy appearance. The thread density can vary, but their main feature is the sheen. They are a good choice for labels that need a touch of gloss.

5.4. The role of thread thickness in woven labels

Denier is an important concept for woven labels. Using finer denier threads, such as 50 denier polyester yarns, is crucial.

Why are finer threads better? These fine threads allow us at Packlove to pack more threads into the label area, resulting in a higher weave density. This, in turn, leads to more detailed designs and softer labels.

Polyester is a common material for these fine threads because it’s strong, can be made very fine, holds color well, and is soft. The denier (thickness) of the polyester yarn is a key factor.

5.5. Impact on visuals and texture

To summarize, a higher weave density combined with finer threads makes labels look and feel much better.

- Visuals: Designs are sharper, text is clearer, and the overall look is more professional and high-quality.

- Texture: The label feels smoother and softer, making it more comfortable against the skin.

6. Choosing the right woven label specifications

6.1. Considering your design complexity

When choosing a woven label, think about how detailed your logo or design is.

- Complex designs: If your design includes small text, fine lines, intricate details, or color gradients, a higher density weave like Damask is recommended. This will clearly capture all those fine elements.

- Simpler designs: For bold logos or clear brand names, Taffeta can be a perfect and cost-effective solution. The “achievable detail level” is still excellent for these types of designs.

6.2. Thinking about label feel and application

Consider where the label will be placed on your product and who will be the end-user.

- Close to skin: For items like baby clothes, lingerie, t-shirts, or garments for sensitive skin, softer labels are essential. Damask is preferred for its softness.

- Outerwear/accessories: For coats, bags, or items where the label has less direct skin contact, Taffeta can be a good, durable option.

6.3. How Packlove can help you choose the best option

Choosing the perfect label might seem challenging, but the Packlove team is here to assist you every step of the way.

- We listen: We take the time to understand your design, your product, and your specific needs.

- We advise: Based on this, we recommend the best woven label type, explaining how weave density will affect your specific design.

- Our goal: We want to ensure you get the perfect label that represents your brand beautifully.

7. Understanding thread count and label density

Here’s a quick summary of the main points:

- Definition: Thread count refers to the total number of threads packed into one square inch of fabric.

- For labels: Higher weave density generally means more detail, a softer feel, and good durability.

- Yarn quality is key: The quality of the yarn used is just as important as the density.

- Choose based on needs: Select your label type based on your design complexity, application, and budget.

8. Frequently Asked Questions (FAQs)

8.1 What is a “good” thread count or density for woven labels?

Answer: There isn’t one single good number; it depends on your design. For very detailed artwork or tiny text, Damask labels offer the highest density for the best and sharpest results. For simpler, bolder designs, Taffeta provides excellent quality and value.

8.2 Does a higher thread density make woven labels scratchy?

Answer: No, usually the opposite is true. High-density weaves, like those in our Damask labels, use very fine, soft threads. This makes the label feel smoother and softer, not scratchy.

8.3 Can I really see the difference that thread density makes in a woven label?

Answer: Absolutely! With higher density labels, like our Damask options, which feature high-definition weaving, you’ll notice sharper details, clearer small text, and smoother lines and curves. The difference is especially noticeable with intricate designs or very small elements.

8.4 Is thread density the only thing I should consider for my woven labels?

Answer: No, while density is very important for detail and softness, it’s not the only factor. Other considerations include the label material (polyester is common for its durability, softness, and color retention), the weave construction (like Damask for detail or Taffeta for simpler looks), label size, colors, the type of fold (how the label is creased for sewing), and how it will be sewn onto your product.

8.5 What are warp and weft threads in my label?

Answer:

- Warp threads: These are the threads that run up and down (lengthwise) on the loom when your label is being made.

- Weft threads: These are the threads woven from side to side (widthwise), going over and under the warp threads. The weft threads create the design and colors in your label.

Explore more:

Still have questions about thread count or choosing the best woven labels for your brand? Contact the Packlove team today! We’re happy to help.