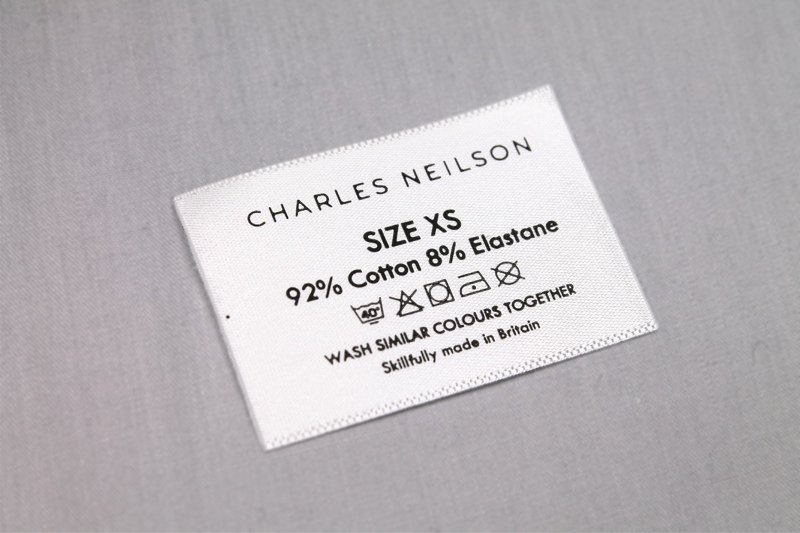

Woven Edge Label: Quality, Durability And Fray Resistance

Elevate your apparel with superior label quality and eliminate fraying concerns. Learn what a woven edge is: a premium finish created during the weaving process, featuring an integrated selvedge for inherent durability and fray resistance. Unlike cut edges sealed after weaving, this method offers a softer feel and lasting neatness.

This guide explains the needle loom production, contrasts woven edge with cut edge and printed labels, and highlights benefits like enhanced brand perception and longevity. Understand if this high-quality, fray-proof option is the right investment to showcase your brand’s commitment to detail.

1. Defining the woven edge

1.1 The core concept: What makes an edge “woven”?

A woven edge signifies a specific type of fabric label where the edges are formed intrinsically during the weaving process itself. The defining characteristic is the selvedge – a self-finished edge created simultaneously with the main body of the label. Imagine the finished edge of a high-quality ribbon; a woven edge label shares this integrated construction.

The warp (lengthwise threads) and weft (crosswise threads) interlace securely right up to the very edge. This prevents the threads from unraveling, making the label a complete, integrated piece right from the start. This technique distinguishes the woven edge as a high-quality type of garment finishing.

1.2 The built-in resistance to fraying

The primary advantage stemming directly from the woven edge, or selvedge, construction is its inherent fray resistance. Because the edge threads are locked into the fabric structure during the weaving process, they resist unraveling much more effectively than a simple raw edge (an edge where fabric threads are cut and exposed) or even some types of cut-and-sealed edges over extended periods.

This structural integrity prevents fraying, contributing significantly to the label’s durability and maintaining a consistently clean finish on the garment throughout its lifespan, unlike an unfinished edge which can quickly look messy.

2. How are woven edge labels made?

2.1 The role of the loom in label quality

Understanding the manufacturing process behind labels reveals how the type of loom used directly influences the final label quality, particularly the characteristics of the edge. The textile industry employs various weaving technologies, but for woven labels, two main types are pivotal: needle looms and broad looms. The choice between these methods dictates whether a label will have a true woven edge or a cut edge, impacting its look, feel, and durability.

2.2 Creating true woven edges (selvedge/tie-knot)

Needle looms are specialized machines designed for weaving narrow fabric strips, often precisely the width of a single label or several labels placed side-by-side. The key feature of this process is that the loom simultaneously constructs the main body of the label and finishes the edges.

As the weft threads travel back and forth, they loop around the outermost warp threads, creating a clean, secure, and integrated edge known as a selvedge on both sides of the ribbon. This method produces what is accurately termed a woven edge label. This finished edge is sometimes also referred to as a “tie-knot edge” due to the way the threads secure the border.

2.3 Understanding cut edge / slit edge labels

In contrast, broad looms operate by weaving large, wide sheets of woven fabric, sometimes spanning several feet across. Individual labels are not formed directly on the loom. Instead, the completed sheet of fabric, containing multiple label designs repeated across its surface, is moved to a secondary cutting process.

Here, labels are separated using methods like heat cut knives or ultrasonic cutting, which simultaneously cut and seal the edges to prevent immediate fraying. The resulting labels are known as cut edge or slit edge labels. It’s crucial to understand that while the label material is indeed woven, the edge itself is cut and sealed, not woven as part of the primary loom process.

Therefore, these are distinct from a true woven edge label. The sealed edge produced by heat or ultrasonic cutting can sometimes feel slightly harder or sharper compared to the softer, naturally finished selvedge of a needle loom label.

3. Woven edge vs. the alternatives

3.1 Woven edge vs. cut edge (slit edge) labels

When choosing woven labels for apparel branding, understanding the difference between woven edge and cut edge (also known as slit edge) is essential. The key distinctions lie in their production and resulting characteristics:

Edge finish:

- Woven edge: Features an integrated selvedge created directly on the needle loom. The edge is soft, naturally finished, and part of the label’s structure.

- Cut edge: Created by cutting labels from a larger sheet woven on a broad loom, then sealing the edge (heat or ultrasonic). The edge finish is sealed, not woven.

Fray resistance:

- Woven edge: Offers inherent, superior fray resistance due to the locked threads of the selvedge.

- Cut edge: Relies on the quality of the seal to prevent fraying. While effective, the seal can potentially degrade over time or with harsh washing.

Feel/texture:

- Woven edge: Generally has a softer, smoother edge that blends seamlessly with the label fabric.

- Cut edge: The sealed edge can sometimes feel slightly harder, stiffer, or have a noticeable ridge compared to the main label body.

Durability:

- Woven edge: The integrated structure often translates to higher long-term durability, particularly regarding edge integrity.

- Cut edge: Good durability, but the edge’s longevity can be influenced by the sealing method and subsequent wear and care.

3.2 Woven edge vs. printed labels

Comparing woven edge labels to printed labels highlights different strengths suitable for varied brand identification goals:

Durability:

- Woven edge: Designs are woven into the fabric, making them as durable as the label material itself. They resist fading and wear exceptionally well.

- Printed label: Designs are printed onto the surface. Ink can potentially fade, crack, or peel over time with washing and friction, affecting appearance quality.

Detail/appearance:

- Woven edge: Offers a classic, often premium look with tangible texture. Excels at sharp text and logos within weaving limitations. High-density weaves allow good detail.

- Printed label: Allows for photographic images, smooth color gradients, and extremely fine details or vibrant colors that are impossible to weave.

Texture/feel:

- Woven edge: Possesses the inherent texture/feel of the woven fabric (e.g., damask, taffeta).

- Printed label: Typically feels smoother and flatter because the ink sits on the surface of the base material (often satin or cotton), unlike woven labels where the texture comes from the threads themselves.

Cost:

- Woven edge: Generally involves a higher initial cost due to the specialized weaving process.

- Printed label: Often more cost-effective, especially for complex, multi-color designs or smaller quantities.

3.3 Key differences at a glance

| Attribute | Woven edge | Cut edge (slit edge) | Printed label |

|---|---|---|---|

| Edge type | Selvedge (woven) | Sealed cut | Cut & sealed (or material edge) |

| How edge is made | Simultaneously during weaving | Cut from wide fabric, then sealed | Cut from base material, sealed |

| Fray resistance | Excellent (inherent) | Good (depends on seal quality) | Depends on base material & edge |

| Weaving/printing | Design woven into fabric | Design woven into fabric | Design printed onto surface |

| Best for detail | Sharp logos, classic text | Sharp logos, classic text | Photos, gradients, fine detail |

| Material feel | Textured (woven fabric feel) | Textured (woven), edge may differ | Often smoother, flatter surface |

| Durability | Very high (design lasts) | High (design lasts) | Moderate (ink may fade/crack) |

| Typical cost level | Higher | Moderate | Lower to moderate |

4. Advantages of choosing woven edge labels for your brand

4.1 Superior durability and longevity

The construction inherent in woven edge labels translates directly to exceptional durability and longevity. Because the selvedge edge is an integral part of the weaving process, it doesn’t rely on a secondary sealing process. This integrated structure inherently possesses superior fray resistance and holds up remarkably well against the rigors of repeated washing cycles, friction from wear, and general handling.

Garments featuring woven edge labels maintain their polished appearance longer, contributing positively to the perceived lifespan of the product and enhancing overall customer satisfaction with the brand’s quality.

4.2 Premium look and feel

Woven edge labels contribute significantly to a premium look and feel, elevating the perceived value of the garment. The clean, soft selvedge edge avoids the potential stiffness or sharpness sometimes found on cut-and-sealed labels. Furthermore, the weaving process itself allows for rich textures and high densities, particularly with preferred fabric material choices like damask (known for its high thread count, softness, and ability to render fine detail) or even classic taffeta.

This tactile and visual quality signals attention to detail and reinforces a high-quality finish, enhancing the overall brand perception and aligning the product with a more sophisticated market position.

4.3 Eliminating fray concerns

One of the most practical advantages is the virtual elimination of concerns about edge fray. The inherent fray resistance provided by the woven selvedge means the label edges will remain neat and intact throughout the normal lifespan of the garment. This provides peace of mind for both the apparel brand, ensuring consistent presentation, and the end consumer, who benefits from a durable, clean finish without unsightly unraveling threads.

5. Considerations and potential downsides

5.1 Cost factor

It’s important to acknowledge the cost factor when considering woven edge labels. They typically represent a higher investment compared to standard cut edge woven labels or many types of printed labels. This price difference stems primarily from the specialized weaving process required.

Manufacturing on a needle loom is often slower and more intricate than weaving broad sheets or printing labels, focusing meticulously on edge quality. However, this higher cost should be viewed as a value proposition: the investment reflects the enhanced durability, superior finish, and premium perception these labels provide.

5.2 Design limitations compared to printing

While offering a premium aesthetic, the weaving technique inherent to woven edge labels does have some design limitations compared to the versatility of printing. Achieving photographic realism, smooth color gradients, or extremely fine, intricate detail (like very small text) can be challenging or impossible with woven threads.

Printed labels, on the other hand, excel in reproducing complex visuals, full-color spectrums, and photo-like images directly onto the label surface. Understanding these technical differences is key to selecting the label type that best aligns with the specific design requirements of your brand identity.

6. Is a woven edge label right for your clothing line?

6.1 Ideal applications

Woven edge labels are particularly well-suited for specific applications where their benefits align perfectly with apparel branding goals. Consider them for:

- High-durability garments: Outerwear, denim jeans, workwear, and children’s clothing benefit greatly from the enhanced fray resistance and longevity.

- Primary brand labels: For main neck labels or prominent exterior brand labels, the premium look and feel reinforce brand quality and recognition.

- Premium garments: High-end fashion lines, bespoke tailoring, accessories, and luxury goods often utilize woven edge labels to signal superior craftsmanship and align with a higher price point.

- Items facing frequent washing: Bed linens, towels, or frequently laundered apparel maintain a neater appearance longer thanks to the durable edge.

In these contexts, the label’s quality directly contributes to the overall perception and lifespan of the product.

6.2 Budget vs. branding strategy

For clothing brands, especially small businesses navigating budget constraints, the decision involves weighing the higher cost against the desired branding strategy. Ask yourself: how critical is ultimate durability and fray resistance for your specific product line? How important is conveying a premium quality perception through details like labeling?

If your brand identity emphasizes longevity, meticulous craftsmanship, or a luxury feel, the investment in woven edge labels can be a strategic choice that reinforces those values. Conversely, if budget is the primary driver or if photographic detail is essential, cut edge woven or printed labels might be more appropriate. Aligning your label choice with both your financial realities and your overarching brand message is key.

7. Related questions

7.1 What materials are typically used for woven edge labels?

The most common materials for woven edge labels are polyester-based yarns due to their durability and versatility. Key types include polyester taffeta, which offers a basic, slightly stiffer feel but allows for sharp detail definition, damask, a higher-density weave known for its softer texture and ability to capture intricate designs, and satin, which provides a smooth, shiny finish often used for a more luxurious appearance.

7.2 Is there a minimum order quantity for custom woven edge labels?

Yes, producing custom labels, including woven edge labels, typically involves a minimum order quantity (MOQ). This requirement exists because setting up the specialized needle loom (or broad loom for cut edge) with a specific design, colors, and dimensions involves significant initial setup time and cost. These MOQs can vary considerably depending on the supplier and the complexity of the label design.

7.3 Can you feel the difference between a woven edge and a cut edge label?

Often, yes, you can feel the difference. The selvedge edge of a true woven edge label generally feels softer, smoother, and more seamlessly integrated into the label fabric. In contrast, a heat-sealed or ultrasonically sealed cut edge can sometimes feel slightly stiffer, sharper, or present a noticeable ridge where the material was melted and fused, although high-quality cutting can minimize this effect.

7.4 How do I attach woven edge labels to garments?

The standard method to attach woven edge labels to garments is by sewing. Common techniques include sewing the label flat onto the fabric surface, folding it into a loop and catching it in a seam (like a neck seam), or sewing it directly into an existing seam allowance during garment construction.

Read more:

Ultimately, selecting true woven edge labels, characterized by their integrated selvedge edge created on needle looms, represents a choice for lasting quality. Their inherent durability and superior fray resistance ensure that your branding remains pristine throughout the garment’s life, contributing significantly to a premium look and enhancing overall brand perception. While they often involve a higher initial investment compared to cut edge or printed labels, the payoff lies in their longevity and the high-end finish they impart. Carefully considering the specific needs of your products and your apparel branding strategy will guide you toward the labeling solution that best reflects your brand’s commitment to quality and detail.