Commercial Patch Embroidery Machine: Buy And Outsource Guide

Bringing patch production in-house with a commercial embroidery machine offers greater control, but it’s a significant commitment requiring a major investment of time, money, and ongoing effort.

This guide will help you understand what these machines do, what to consider before buying one, and whether it’s the right choice for your business. We’ll also explore why outsourcing your custom patch needs to an expert like Packlove can be a smarter, more efficient alternative.

1. What is a commercial patch embroidery machine?

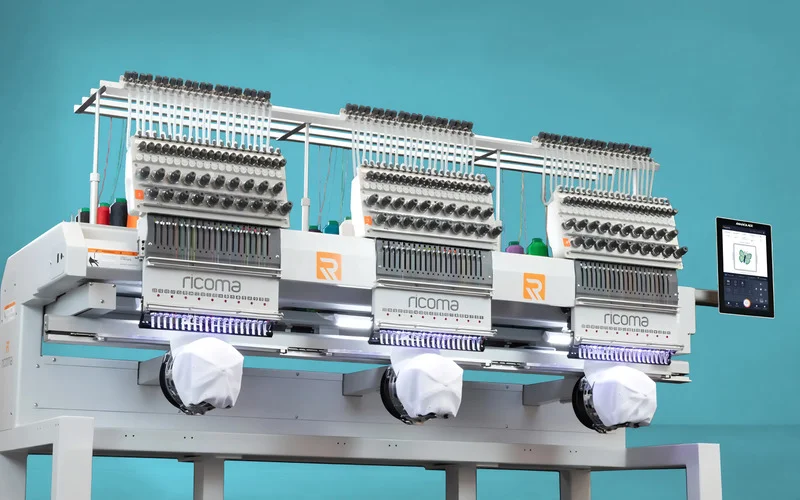

A commercial patch embroidery machine is very different from a small machine you might use at home for hobbies. These machines are built for businesses that need to make many high-quality embroidered items, like patches, often and quickly.

They are specifically designed for the demands of business production. Let’s look at what makes them special.

1.1. Built for lots of work

These machines are built for endurance. Constructed with robust, often all-metal parts, they are designed to operate for long hours daily and last for years, even under extensive use. Unlike home machines with more plastic components, commercial models are made for constant, heavy-duty production, making durability a key factor for any business needing patches regularly.

1.2. Faster stitching

This high stitching speed means you can produce more patches in less time, significantly boosting your business’s production capacity. However, the key is to balance speed with quality, as the best machines maintain excellent stitch integrity even at top speeds.

1.3. More needles

Many commercial machines have a multi-needle capability. This means they have several needles, such as 4, 6, 10, or more. Each needle can hold a different color of thread.

If your patch design has many colors, the machine can switch between them by itself using its automatic color change feature. With a single-needle machine, a person has to stop the machine and change the thread by hand for every new color. More needles save a lot of time and make it easier to create colorful patches.

1.4. Bigger embroidery area

The embroidery area determines how large a design the machine can sew. Commercial machines usually have bigger hoop size options, which are the frames that hold the fabric tight. This means they can make larger patches or sew several small patches at the same time in one large hoop. This capability gives you more options for different kinds of patches.

2. Key features to look for in a commercial patch embroidery machine

When you’re thinking about buying a commercial patch embroidery machine, there are many features to consider. Knowing these will help you choose the best machine for making patches.

2.1. Number of needles

The number of needles a machine has is a very important feature, especially for making colorful patches.

- Single-needle machine: This type of machine has only one needle. You must stop the machine and change the thread by hand for each new color in your design. While some commercial single-head options exist, they are less efficient for patches with multiple colors.

- Multi-needle machine: This machine has multiple needles, ranging from 4 to 15 or even more. Each needle can be threaded with a different color. The machine uses its multi-needle capability to automatically select the correct needle and color for each part of the design. For making patches, which often have several colors, multi-needle machines are much faster and easier to use.

The benefits of a multi-needle machine are significant for patch making. The automatic color change is the biggest advantage, as the machine switches colors by itself. This means less work for the operator and allows you to set up the machine to sew different colors without stopping for thread changes. This leads to increased efficiency and a lower chance of making mistakes.

2.2. Embroidery area and hoop size

The embroidery area, also called hoop size, determines the maximum size of the patch you can create. The hoop is the frame that holds the fabric tight while the machine sews on it. The size of this hoop tells you the biggest single patch design you can make.

Think about what size patches you will make most often. Choose a machine with hoop size options that are good for these common sizes, and ensure it can handle the largest patch you might want to create. A larger hoop capability gives you more flexibility, such as making big patches for jacket backs or sewing many small patches at once.

Some machines can also use special frames beyond standard flat hoops. Examples include cap frames for hats or magnetic frames, which make it easier to hold certain materials securely.

2.3. Stitch speed

Stitch speed is how fast the machine can sew, but faster isn’t always better if quality suffers. Stitches per minute (SPM) tells you the maximum embroidery speed of the machine. A higher SPM number means the machine can sew faster.

Sewing faster usually means you can make more patches in a day, which is important for high-volume production. However, sewing at the fastest speed is not always best. For very detailed designs or certain fabrics, sewing too fast can degrade stitch quality. Good machines can sew fast while maintaining excellent stitch integrity, but it’s something to be aware of.

2.4. Machine construction and durability

A commercial machine is a big investment, so it needs to be built to last. A business-grade embroidery machine for patches needs to be strong and durable. For a buyer, durability and reliability are key concerns. This means it can work hard for many hours without frequent breakdowns.

Look for machines with a strong metal frame and internal metal parts, not mostly plastic. A durable machine means less repair time and a better investment over many years.

2.5. Software compatibility and connectivity

Embroidery machines need a special digital file that tells the machine where to put each stitch and what color to use. This file is created using embroidery digitizing software like Wilcom or Hatch. The quality of the digitized design file is critical; even the best machine cannot produce a good patch from a poorly digitized design.

The machine’s control panel is also important. Many modern machines have a user-friendly touchscreen interface that simplifies operation, making it easier to load designs, pick colors, and monitor progress. Designs are typically transferred from your computer to the machine via a USB port, though some newer models offer Wi-Fi or direct cable connections.

2.6. Other important features

Beyond the main specifications, some other features can make a big difference in daily use.

- Automatic thread trimmers: These automatically cut the threads when the machine changes colors or jumps between parts of a design. This saves a lot of time as you don’t have to cut small threads by hand, resulting in cleaner patches.

- Thread break sensors: These sensors detect if a top thread breaks or the bobbin thread runs out. The machine stops automatically and alerts the operator, preventing flawed patches and saving material and time.

- Built-in camera: This is a feature on more expensive machines that helps the operator see the fabric in the hoop on the screen. It allows for very precise design placement, which is helpful when exact positioning is critical.

3. Understanding patch-specific needs

Making great patches has unique requirements that go beyond general embroidery.

3.1. Working with patch backing materials

Patches are usually made by embroidering on a base fabric, like twill or felt. After embroidering, another layer is often added to the back, like an iron-on adhesive. The machine needs to sew well on the chosen patch fabric, which can be thicker than regular clothing fabric.

A common method is to embroider the design on a larger piece of this backing material and then cut the patch out.

3.2. Achieving clean edges and detailed logos

Good patches need to look sharp. This means having clean, neat edges (like a satin stitch border) and clear details in logos and text. Merrowed edges are also common but are created with a separate machine after embroidery.

The best commercial embroidery machine for detailed logos will offer excellent stitch control. This precision, combined with a professionally digitized file, is essential for achieving high-quality results.

4. The reality: Investing in in-house patch production

Owning a commercial embroidery machine seems like a great way to control your patch production. However, it’s important to understand all the costs and commitments involved before you decide.

4.1. The upfront cost

The initial price is just the beginning. A commercial patch embroidery machine can range from around $5,000 for a smaller model up to $20,000 or more for larger machines with more features.

Besides the machine, you’ll need to buy other items:

- Software: Good embroidery digitizing software is essential and can cost hundreds or even thousands of dollars.

- Supplies: You’ll need thread in many colors, backing fabrics like twill, stabilizers to support the fabric, needles, and bobbins.

- Hoops: You may need to buy extra hoop sizes if the machine doesn’t include all the sizes you need.

- Other tools: A small toolkit, machine oil, and other minor accessories might be necessary.

4.2. The learning curve

Using these machines and creating designs takes skill and time to learn. You need to learn how to set it up correctly, hoop the fabric properly, choose the right needles and threads, adjust thread tension, and fix small problems.

Embroidery digitizing is a special skill, different from graphic design. It requires understanding stitch types, density, and how fabric behaves. It takes a lot of practice to become good at it, or you may need to pay someone to digitize your designs.

4.3. Time commitment

Making patches yourself takes a significant amount of time. Consider the time needed to digitize the design, set up the machine, let the machine sew, and add finishing touches. You need to realistically assess if you or your team have this much time available.

Every new job requires setup, and regular maintenance is very important to keep the machine working well. This includes cleaning, oiling, and sometimes professional servicing, which also takes time and can involve costs.

4.4. Space requirements

Commercial embroidery machines can be quite big and heavy. You need a sturdy, stable surface for the machine itself, plus space around it for supplies, finished products, and for you to work comfortably. The machine’s footprint is an important consideration.

5. Is buying a commercial embroidery machine right for your business?

Deciding whether to invest in a commercial embroidery machine is a big step. It’s about whether it makes business sense for your specific situation. Thinking through these questions will help you decide.

- How many patches do you need regularly? If you have a high, consistent need for patches, a machine might eventually pay for itself. If you only need them occasionally in small numbers, it might not be cost-effective.

- Do you have the budget? Remember the full cost: the machine, software, supplies, training, and future repairs. Can your business afford this large upfront investment and ongoing expenses?

- Do you have the time and staff? Who will learn to use the machine and digitize designs? If current staff take this on, will it affect their other duties? Hiring someone new adds to your costs.

- Do you have the space? Do you have enough room for the machine, all the supplies, and a comfortable workspace?

5.1. When it might be a good idea

In some situations, buying a machine makes sense.

- You have a very high, consistent need for patches.

- You want to start a business that focuses mainly on embroidery.

- You have someone who can dedicate their time to learning and running the machine effectively.

5.2. When it might not be the best idea

For many businesses, owning a machine isn’t the most practical choice.

- You only need patches sometimes or in small numbers.

- Your budget is tight, and the total cost is too much right now.

- You need many different branding items, and patches are just one small part of your strategy.

- You prefer to focus on your main business activities, not on manufacturing.

6. Partnering with Packlove for expert results

If the significant investment in equipment, time, and skill development seems overwhelming, there’s a more strategic path. Partnering with a specialist like Packlove allows you to access premium custom patches while focusing your resources on what you do best: building your brand.

6.1. Why outsourcing to Packlove is a smart business decision

- Access expertise, not equipment: you gain immediate access to our team’s deep knowledge of materials, design, and production. We ensure your patches are professional and impactful, without you needing to learn complex software or machine maintenance.

- Guaranteed quality and consistency: we are specialists in branding production. Every order, whether small or large, meets our high standards for stitch quality and color accuracy, ensuring your brand is always represented perfectly.

- Strategic design and material guidance: unsure if your design will translate well to embroidery? Need advice on whether woven or rubber patches would better suit your brand? Our team acts as your consultant, helping you make the best choices for your specific needs.

6.2. A full suite of branding solutions

Your branding needs may go beyond a single product. Packlove is your comprehensive partner for a variety of high-quality branding items:

- Woven labels: for capturing intricate details and fine text with a sophisticated, premium finish.

- Rubber labels (PVC/Silicone): for a modern, durable, and tactile 3D effect ideal for outerwear and activewear.

- Heat transfer labels: for a comfortable, tagless application perfect for t-shirts and performance wear.

6.3. Our simple, streamlined process

Getting professional custom patches is effortless with Packlove:

- Share your vision: send us your design, desired size, and quantity.

- Receive a clear quote: we provide a transparent, all-inclusive price for your project.

- Approve your digital proof: our team refines your design for production and sends a digital proof for your final approval.

- Receive your patches: we handle all the production complexities and ship the finished, high-quality patches directly to you.

7. Frequently asked questions about commercial patch embroidery

7.1. How much do commercial embroidery machines cost?

Prices vary greatly. A basic commercial machine might start around a few thousand dollars, while more advanced models with multiple needles and larger hoops can cost tens of thousands.

7.2. What software is needed for commercial embroidery machines?

You need special embroidery design software, like Wilcom or Hatch, to digitize your artwork into stitch files. This is often a separate and important purchase.

7.3. Can I embroider patches on a regular sewing machine?

It’s very difficult to create professional-quality patches on a home sewing machine. They are not built for the thick materials and dense stitching required, and the quality will likely be poor.

7.4. How long does it take to make an embroidered patch?

The time depends on the patch’s size, stitch count, and machine speed. A small, simple patch might take a few minutes, while a large, detailed one could take much longer. This doesn’t include design, digitizing, or setup time.

Explore more:

Bringing patch production in-house is a major undertaking that requires a significant investment in equipment, time, and skill. However, it’s not the only path to professional results.

For businesses that value their time and want guaranteed quality without the operational burden, outsourcing to a specialist like Packlove is often the smarter business decision.

We handle the production complexities, allowing you to focus on what you do best: building your brand. Ready to explore the best path for creating beautiful custom patches? Our team is here to help.