Key Garment Industry Terms for Your Clothing Business

Stepping into the world of fashion production can feel like learning a new language. For clothing business owners, especially newcomers, the specific garment industry terms and acronyms used by suppliers and manufacturers can be overwhelming.

Misunderstanding this apparel business vocabulary can lead to costly mistakes and delays. This article serves as a practical glossary, designed to demystify essential terms related to fashion production.

By understanding this language, you’ll be equipped to communicate clearly with partners, reduce errors in sampling and production, and ultimately run your operations more smoothly, laying a stronger foundation for your apparel business.

1. Why mastering garment industry vocabulary is crucial?

Confusion over garment industry terms isn’t just frustrating; it directly impacts your bottom line.

- Avoiding costly errors: Misinterpreting terms like MOQ (minimum order quantity) can lead to ordering far more inventory than needed, tying up cash flow. Similarly, misunderstanding shipping terms like FOB (freight on board) versus LDP (landed duty paid) can result in unexpected freight and duties costs, eroding your gross margin (the difference between revenue and the cost of goods sold). Clarity prevents these expensive mistakes.

- Building stronger partnerships: Speaking the language of your suppliers and factories builds credibility and trust. When you understand their terminology and processes, communication becomes more effective, fostering better working relationships crucial for long-term success. This foundation of trust is vital when negotiating contracts and lead times (the time from order confirmation to shipment).

- Streamlining your workflow: Knowing the correct terms speeds up every stage, from design hand-offs to production approvals. Clear communication reduces back-and-forth questions and revisions, improving overall efficiency in your workflow.

- Empowering negotiation: Understanding costing terms and shipping responsibilities allows you to negotiate more effectively. Whether discussing unit prices, payment schedules, or who covers import duties, fluency in industry vocabulary puts you in a stronger position.

2. Key garment industry terms demystified: A step-by-step guide

2.1 Laying the foundation: Design & development vocabulary

Term: Tech pack

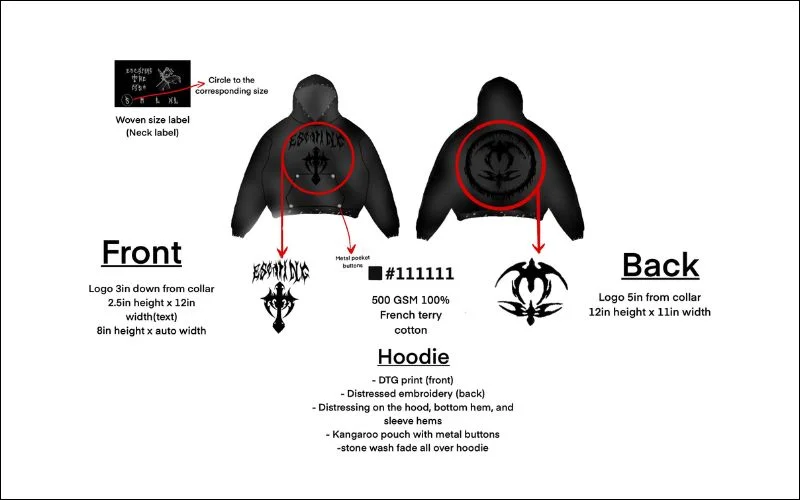

A tech pack (technical package) is the essential blueprint for your garment. This comprehensive document provides all manufacturing instructions needed for a factory to produce your design accurately. Key components typically include technical sketches (detailed drawings of the garment), specs (specifications or measurements), a BOM (bill of materials listing all components), and detailed garment construction notes.

A thorough tech pack is crucial because it ensures the manufacturer understands your exact design intent, minimizing production errors, standardizing quality across units, and serving as a clear reference document, almost like a contract for production.

Term: CAD (computer-aided design) / flat sketch (technical sketch)

CAD (computer-aided design) refers to the software used by designers to create digital designs and patterns. A flat sketch, or technical sketch, is a specific output usually created using CAD but can also be drawn by hand.

This is a precise, two-dimensional technical drawing showing the garment as if laid flat, clearly illustrating all seams, stitching details, pockets, closures, and other design elements from the front and back views (and sometimes side or inside views).

Its importance lies in providing unambiguous visual communication for pattern makers and factory teams, ensuring everyone interprets the design details consistently and accurately.

Term: BOM (bill of materials)

The BOM (bill of materials) is a critical section within the tech pack. It’s a detailed list itemizing every single raw material and component required to produce one unit of the garment.

This includes the main fabric, lining fabric, thread types and colors, buttons, zippers, interfacing, elastic, brand labels, care labels, hang tags, individual poly bags for packaging, and even shipping poly mailers if applicable, along with the specific quantity needed for each.

The BOM is crucial for accurate garment costing, enabling efficient material sourcing and inventory management, and ensuring the factory uses the exact components specified in your design.

Term: Prototype / sample types (proto, fit, PP, TOP, SMS)

A prototype or sample is a physical version of the garment created during the development process before bulk production. Different sample types serve specific purposes at various stages:

- Proto sample: Often the very first sample made to check the basic design concept, construction, and silhouette.

- Fit sample: Created specifically to check the garment’s measurements, fit, and drape on a live fit model or dress form. Multiple rounds of fit samples might be needed.

- PP sample (pre-production sample): A critical sample made using the actual bulk fabric, trims, and construction methods. This is the final check and approval benchmark before starting the main production run.

- TOP sample (top of production sample): A garment pulled randomly from the beginning of the actual bulk production run to ensure consistency and quality compared to the approved PP sample.

- SMS (salesman sample): Samples created for sales teams or showrooms to show potential buyers, often produced before bulk production is fully complete.

The sampling process is essential for verifying the design, fit, construction details, and overall quality, allowing for necessary corrections before committing to the expense and volume of bulk production.

Term: Grading / grade rules

Grading is the technical process of proportionally increasing or decreasing the size of a base pattern (usually the sample size, e.g., medium) to create patterns for the full range of sizes you intend to offer (e.g., XS, S, M, L, XL, XXL).

Grade rules are the specific measurement increments defined for how much each point of measure changes between consecutive sizes to maintain the intended fit, proportions, and style across the entire size range. Proper grading is vital for ensuring consistent fit for all customers, which directly impacts satisfaction and helps minimize returns due to sizing issues.

Term: Specs (specifications) / spec sheet

Specs (specifications), typically presented in a spec sheet format within the tech pack, detail the exact finished garment measurements required for key points on the garment. These measurements are listed for each size in your range.

Each measurement point is often called a POM (point of measure). Crucially, the spec sheet also includes tolerance levels – the acceptable small variance (e.g., +/- 0.5 cm) allowed for each measurement. Specs provide the factory with precise measurement targets and define the acceptable range for quality control inspections, ensuring garments meet your sizing standards.

Term: Mood board / line sheet

These are two distinct visual tools used at different stages:

- Mood board: Primarily an internal tool used during the early design phase. A mood board is a visual collage combining images, color palettes, fabric swatches, textures, and inspirational tear-outs to establish the overall theme, feeling, and aesthetic direction for a collection.

- Line sheet: An external sales tool, typically a digital or printed document created for wholesale buyers. A line sheet presents the collection concisely, showing product flat sketches or photos, style numbers or SKUs (stock keeping units), brief descriptions, available colorways, material composition, size ranges, and crucially, the wholesale prices.

The mood board guides the creative vision, while the line sheet is essential for presenting the collection professionally and facilitating wholesale orders.

2.2 Gathering the goods: Sourcing & materials terminology

Term: Sourcing

Sourcing is the strategic business process of identifying, evaluating, negotiating with, and ultimately selecting and engaging suppliers, mills (factories specializing in fabric production), or manufacturing factories. This involves finding partners for all necessary raw materials (fabrics, trims), components (like zippers or buttons), and production services (like cutting and sewing). Choosing the right partners through effective sourcing is critical, as it directly impacts your product quality, cost, delivery times, ethical compliance, and production capacity.

Term: Supplier / vendor / mill

These terms refer to the businesses providing goods or services for your production:

- Mill: Typically refers specifically to a factory that manufactures textiles (e.g., a weaving mill produces woven fabrics, a knitting mill produces knit fabrics).

- Supplier / vendor: These are broader, often interchangeable terms encompassing any provider of necessary goods or services. This can include fabric suppliers (who might be mills or distributors), trim suppliers (providing items like brand labels, care labels, hang tags, buttons, zippers, or even packaging like poly mailers and zipper bags), or even the finished goods manufacturer themselves (especially in an FPP model). Building strong relationships with reliable suppliers is fundamental for consistent quality and on-time delivery.

Term: Fabric basics (greige goods, GSM, hand feel)

Understanding basic fabric terminology helps in specifying and selecting materials:

- Greige goods (pronounced “gray goods”): Refers to raw woven or knitted fabric straight off the loom or knitting machine that has not yet undergone any finishing processes like bleaching, dyeing, or printing.

- GSM (grams per square meter): A standard unit of measurement indicating the weight or density of a fabric. Higher GSM generally means a heavier, thicker fabric.

- Hand feel (or simply “hand”): Describes the tactile quality of the fabric when touched – its perceived softness, smoothness, stiffness, drape (how it hangs), and texture.

Knowing these helps you accurately communicate the desired fabric characteristics to mills and suppliers, ensuring the final material aligns with your design vision and quality standards.

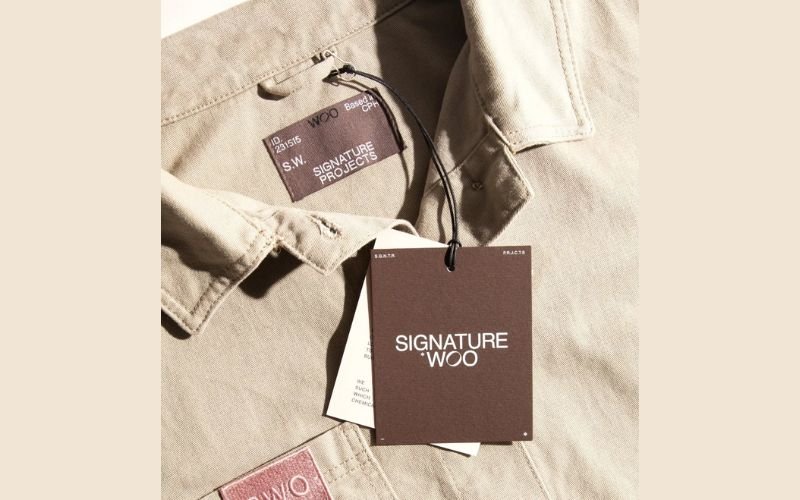

Term: Trims / findings

Trims (sometimes also called findings, a slightly more technical term) encompass all the items used to finish a garment besides the main body fabric. This is a broad category including functional and decorative elements like: woven labels, printed care labels, size labels, hang tags, buttons, zippers, snaps, hooks & eyes, drawcords, ribbons, elastic, interfacing (material used to stiffen areas like collars), twill tape, etc.

Sourcing high-quality trims is essential not just for the garment’s functionality and durability, but also for branding – think custom-branded woven labels, hang tags, or even zipper pulls. The quality and appearance of trims significantly impact the perceived value and overall aesthetic of the final product. For businesses, securing reliable suppliers for specific branded components like labels and tags is a key sourcing task.

Term: Lab dip / strike off / handloom

These are crucial small samples of materials provided by suppliers for your approval before they produce the bulk quantity:

- Lab dip: A small swatch of fabric custom-dyed by the supplier’s lab to match a specific color standard you provide (often a Pantone color code or a physical swatch). Multiple attempts might be needed to get the color right.

- Strike off: A small sample of fabric printed with your design. Used to approve the print’s colors, scale, placement, and overall look before printing the bulk fabric yardage.

- Handloom: A small swatch of woven fabric created on a handloom (or sometimes a small production loom) to show the intended weave pattern, structure, colors, and hand feel before weaving the bulk fabric.

Approving these samples is a critical step. Failure to do so risks receiving bulk materials that don’t match your specifications, leading to potentially unusable inventory and significant financial loss.

Term: COO (country of origin)

COO (country of origin) indicates the country where the product underwent its last substantial transformation, which for apparel usually means where the garment was sewn and assembled. This information is legally required to be stated on the care label for garments sold in many regions, including the United States.

Beyond legal compliance, the COO can also significantly impact import duties and tariffs (taxes on imported goods) and may influence consumer perception regarding quality or ethical production.

2.3 Bringing designs to life: Manufacturing & production jargon

Term: Manufacturer / factory

A manufacturer or factory is the business entity or physical facility responsible for carrying out the actual garment production. This typically involves interpreting the tech pack, cutting the fabric according to the patterns, sewing (assembling) the garment pieces, adding trims, and performing finishing processes.

Selecting the right manufacturing partner is one of the most critical decisions for a clothing brand, impacting product quality, production cost, lead times, communication ease, and adherence to ethical and sustainable practices.

Term: CMT (cut, make, trim) vs. FPP (full production package)

These terms describe two primary models for outsourcing apparel production:

- CMT (cut, make, trim): In this model, the brand is responsible for sourcing and providing the factory with all the raw materials – fabric, trims, labels, packaging. The factory’s service is limited to cutting the fabric, sewing (making) the garments, and adding the trims.

- FPP (full production package) or full service: Here, the factory takes on a much broader scope of responsibility. Based on the brand’s tech pack and approved samples, the factory handles everything, including sourcing the fabric and all trims, in addition to the cutting, making, and finishing processes.

The choice between CMT and FPP has major implications for a brand’s operational involvement, level of control over materials, cost structure, and required internal expertise. CMT often appears to have a lower per-unit service cost, but requires the brand to have strong sourcing capabilities and manage material logistics.

FPP offers convenience and simplicity, especially for startups, but potentially comes at a higher overall cost and offers less direct control over material choices and costs.

| Feature | CMT (cut, make, trim) | FPP (full production package) |

|---|---|---|

| Material sourcing | Brand sources & provides all materials | Factory sources materials based on tech pack |

| Cost structure | Pays factory for labor/assembly only | Pays factory an all-inclusive price per unit |

| Brand control | High control over material choice & cost | Less direct control over material specifics |

| Convenience | Requires more brand effort & expertise | Simpler, more hands-off for the brand |

| Suitable for | Brands with strong sourcing capabilities | Startups or brands prioritizing convenience |

Term: MOQ (minimum order quantity)

MOQ (minimum order quantity) refers to the smallest number of units (per style, sometimes per color within a style, or a total order value) that a supplier or manufacturer requires a customer to order for them to accept the production run.

This is a critical factor, especially for small businesses and startups with limited budgets and potential storage space. Factories and material suppliers (including those for fabrics, labels, tags, and zippers) set MOQs to ensure production efficiency and cover their setup costs.

High MOQs can pose significant challenges, potentially leading to excess inventory and straining cash flow. Negotiating MOQs or finding partners specializing in lower quantities is often a necessary step for emerging brands.

Term: Lead time

Lead time is the total duration between placing a confirmed purchase order with a manufacturer (often after an initial deposit is paid) and the date the finished goods are completed and ready to leave the factory (known as the ex-factory date).

This timeframe typically encompasses stages like sourcing and receiving materials (especially in FPP), production planning and scheduling, fabric cutting, sewing/assembly, finishing processes (like washing or pressing), quality control inspections, and final packing.

Understanding and confirming lead times is crucial for accurate business planning, setting realistic collection launch dates, coordinating marketing campaigns, and managing inventory flow. Lead times can vary significantly based on the factory’s capacity, the complexity of the garment, the order size, and the time of year.

Term: Production run / bulk

The production run, often referred to as bulk production, is the main manufacturing phase where the primary quantity of your order is produced. This stage commences only after the pre-production (PP) sample has been thoroughly reviewed and formally approved by the brand. During the bulk run, the factory focuses on efficiently and consistently producing the garments according to the approved standards.

Term: Quality control (QC) / AQL (acceptable quality limit)

Quality control (QC) encompasses the set of processes, checks, and inspections implemented to ensure that the finished garments meet the pre-agreed quality standards and specifications outlined in the tech pack and approved samples.

This involves checking measurements, construction quality, visual appearance, fabric integrity, and trim application. QC can occur at various points: during production (in-line QC) or after production is complete (final QC).

AQL (acceptable quality limit) is a statistical sampling method commonly used during final inspections. It defines the maximum percentage or number of defective items considered acceptable within a randomly selected sample of the production batch.

If the number of defects found exceeds the AQL, the entire batch may be rejected or require further inspection/rework. Robust QC processes are essential for maintaining brand reputation, ensuring customer satisfaction, and minimizing costly returns or unsellable inventory.

Quality assurance (QA), often mentioned alongside QC, focuses more broadly on implementing processes and systems designed to prevent defects from occurring in the first place, whereas QC focuses on detecting defects in finished products.

2.4 Getting products moving: Logistics & shipping language

Term: Incoterms (focus on FOB, LDP/DDP)

Incoterms (international commercial terms) are a set of standardized rules published by the International Chamber of Commerce that define the specific responsibilities of buyers and sellers in international trade transactions.

They clarify who is responsible for arranging and paying for shipping, insurance, customs clearance, duties, and where the risk of loss or damage transfers from seller to buyer. Two common incoterms for apparel businesses are:

- FOB (freight on board or free on board): Under FOB terms (usually followed by a named port of origin, e.g., FOB Shanghai), the seller is responsible for all costs and risks until the goods are loaded onto the shipping vessel (ship or aircraft) at the designated origin port. From that point onwards, the buyer assumes responsibility for the main international freight costs, insurance, customs clearance in the destination country, import duties and taxes, and final delivery.

- LDP (landed duty paid) / DDP (delivered duty paid): These terms place the maximum responsibility on the seller. The seller is responsible for arranging and paying for all costs associated with delivering the goods right up to the buyer’s specified destination (e.g., their warehouse). This includes international shipping, insurance, customs clearance, and all import duties and taxes. DDP is technically the official Incoterm, but LDP is frequently used in the apparel industry with essentially the same meaning.

Understanding these terms is absolutely critical for accurately calculating the total landed cost of your products and for clear budgeting. The chosen Incoterm directly dictates who pays for significant portions of the logistics process, greatly impacting your final product cost.

Term: Freight forwarder

A freight forwarder is a company that acts as an intermediary or agent to organize and manage shipments on behalf of businesses. They don’t typically own the ships or planes themselves but leverage their network and expertise to handle the complex logistics of moving goods from the manufacturer’s location to the buyer’s final destination.

Their services often include booking cargo space with carriers (sea freight or air freight), preparing and managing shipping documentation, arranging inland transportation, warehousing (if needed), and often handling customs clearance procedures. Freight forwarders are particularly valuable for businesses, especially those new to international shipping, as they simplify the process and navigate the complexities involved.

Term: Duty / tariffs

Duty (or tariffs) are taxes imposed by a country’s government on goods imported into that country. The amount of duty payable typically depends on several factors: the type of product being imported (classified using an internationally standardized HS code – harmonized system code), the declared value of the goods, and the country of origin (COO) where the goods were manufactured.

Import duties can significantly increase the final landed cost of your products. This cost must be carefully factored into your pricing strategy and overall budget, unless you are purchasing goods under DDP (delivered duty paid) or LDP (landed duty paid) Incoterms, where the seller is responsible for covering these costs.

Term: Logistics

Logistics refers to the comprehensive management of the flow of things between the point of origin and the point of consumption to meet requirements. In the context of a clothing business, this involves the planning, implementation, and control of the efficient, effective forward and reverse flow and storage of goods (raw materials, components like labels and tags, and finished garments), services, and related information.

The goal is to get the right products to the right place at the right time in the desired condition, while making the greatest contribution to profitability. Efficient logistics are essential for ensuring timely deliveries to customers or retailers, minimizing transportation and warehousing costs, and effectively managing inventory levels throughout the supply chain.

Term: Packaging considerations

Packaging considerations involve the selection and planning of all materials used to wrap, contain, and protect finished garments during storage, transit, and potentially for retail presentation. This includes:

- Individual garment protection (e.g., clear poly bags to keep items clean).

- Inner cartons (smaller boxes holding a set quantity of garments).

- Master cartons (larger, sturdier boxes containing multiple inner cartons, used for shipping).

- Potentially, branded shipping materials like custom-printed poly mailers or boxes, especially for direct-to-consumer (D2C) e-commerce businesses.

Packaging choices are important for protecting garments from damage, dirt, and moisture during shipping and handling. Packaging also contributes to the brand’s presentation and customer unboxing experience (particularly for D2C). Furthermore, the weight and dimensions (volume) of packaging directly impact shipping costs, so efficiency needs to be considered during the sourcing and costing stages.

2.5 Understanding the numbers: Costing & business operations terms

Term: Cost sheet / garment costing

A cost sheet is a detailed breakdown document used internally to meticulously calculate the total cost required to produce one single unit of a specific garment style. This process is known as garment costing. The cost sheet typically itemizes expenses such as: cost of all raw materials (fabric, thread, all trims like labels, buttons, zippers), labor costs (often represented by the CMT cost quoted by the factory), factory overhead contributions, costs for special finishing processes (like washing or printing), individual packaging costs (like poly bags and hang tags), and sometimes includes estimated initial logistics costs depending on the agreed Incoterms (e.g., transport to the port for FOB).

Accurate garment costing is absolutely fundamental for setting appropriate wholesale and retail prices, calculating profit margins, making informed decisions about product viability, and managing the financial health of the business.

Term: Wholesale price vs. retail price

These two prices represent different points in the sales channel:

- Wholesale price: This is the price at which a brand sells its products in bulk or larger quantities to other businesses, typically retailers (like boutiques, department stores, or online marketplaces) who will then resell the products to the end consumer.

- Retail price (often referred to as MSRP – manufacturer’s suggested retail price): This is the final price that the end consumer pays for the product when purchasing it from a retailer.

Understanding the distinction and the typical relationship between these two prices (wholesale is significantly lower than retail) is crucial for developing a sound pricing strategy, managing relationships with retail partners (B2B – business-to-business), reaching end consumers (B2C – business-to-consumer), and calculating profit margins at both the brand and retail levels.

Term: Margin / markup (gross margin, IMU, keystone)

These terms relate to profitability calculations:

- Markup: The amount added to the cost price of a product to arrive at its selling price. Can be expressed as a fixed amount or a percentage of the cost. (Markup = Selling Price – Cost).

- Margin (usually gross margin): Profitability expressed as a percentage of the selling price. Calculated as (Selling Price – Cost) / Selling Price. Gross margin indicates how much of each sales dollar is left after accounting for the direct cost of producing the goods sold (COGS).

- IMU (initial markup): The planned markup percentage calculated before any potential discounts, markdowns, or allowances are considered.

- Keystone pricing: A common, simple pricing strategy where the wholesale price is doubled to determine the retail price. This results in a 100% markup on the wholesale cost, or a 50% gross margin at the retail level.

Understanding these concepts is essential for running a profitable business. They guide strategic pricing decisions to cover all business costs and achieve desired profit levels.

Term: SKU (stock keeping unit)

A SKU (stock keeping unit) is a unique alphanumeric code assigned to each distinct product variant for inventory management purposes. Each unique combination of style, color, and size gets its own SKU. For example, a blue medium t-shirt might have the SKU TSHIRT-BLUE-MED, while the blue large version would have a different SKU like TSHIRT-BLUE-LRG.

SKUs are absolutely essential for accurately tracking inventory levels, managing stock across different sales channels (website, retail store, wholesale), processing orders efficiently, fulfilling customer purchases correctly, and analyzing sales data to understand which specific variants are selling well.

Term: Invoice / payment terms (e.g., Net 30)

- Invoice: A formal commercial document issued by a seller (e.g., your factory, fabric mill, or trim supplier) to the buyer (your business). It details the products or services provided, quantities, agreed prices per unit, total amount due, and often includes payment instructions and terms.

- Payment terms: The conditions agreed upon between the buyer and seller that specify when payment for the invoice is due. Common examples include: Net 30 (payment due 30 days after the invoice date), Net 60 (due in 60 days), PIA (payment in advance – payment required before goods are shipped or produced), 50/50 (often 50% payment required upfront to start production, and the remaining 50% due before shipment).

Understanding and negotiating payment terms is crucial for managing cash flow effectively for both your business and your suppliers. Clear terms avoid misunderstandings and ensure timely payments are made and received.

3. Related questions

3.1 What’s the main difference between a tech pack and a BOM?

Think of the tech pack as the complete instruction manual or blueprint for building a garment. It contains everything the factory needs: sketches, construction details, measurements (specs), and more. The BOM (bill of materials) is just one specific part of that tech pack.

The BOM focuses solely on listing every single physical item needed to make one unit – like fabric, thread, buttons, zippers, labels, and tags – along with the quantity of each. So, the tech pack is the comprehensive guide, while the BOM is the detailed shopping list within that guide.

3.2 How do FOB and LDP/DDP incoterms affect my budget?

The key difference lies in who pays for shipping costs and import duties, which significantly impacts your budget predictability. With FOB (freight on board), the price quoted by your factory only covers costs up to loading the goods onto the ship at the origin port.

You (the buyer) are then responsible for paying the main international shipping fees, insurance, and crucially, any import duties and customs clearance fees when the goods arrive in your country. This means your total cost can fluctuate based on shipping rates and taxes.

With LDP (landed duty paid) or DDP (delivered duty paid), the factory’s quoted price includes all those costs – shipping, insurance, duties, and delivery to your door. This offers much greater budget predictability as the total landed cost is known upfront.

Yes, absolutely. Just like garment factories have MOQs for producing clothing styles, suppliers of trims like labels, hang tags, zippers, and even custom packaging often have their own MOQs. This can sometimes create a challenge for small businesses.

For instance, the MOQ for custom woven labels might be 1000 pieces, even if your garment production run is only 200 pieces per style. This means you might need to order more trims than immediately necessary, tying up cash and requiring storage. Planning your trim needs across multiple styles or seasons, or actively seeking specialized trim suppliers who cater to lower MOQs, becomes important.

3.4 Is using a CMT factory always cheaper than using an FPP factory?

Not necessarily, when considering the total cost. While the direct service fee charged by a CMT (cut, make, trim) factory for just the sewing labor is typically lower than the all-inclusive price from an FPP (full production package) factory, the final cost comparison depends heavily on your brand’s ability to source materials effectively. With CMT, you bear the cost and effort of finding, negotiating, purchasing, and delivering all fabrics and trims.

If you can source materials very efficiently at low costs, CMT might result in a lower total product cost. However, FPP offers convenience and leverages the factory’s sourcing network, which might secure materials at competitive prices due to their volume. FPP bundles all costs, offering simplicity, but potentially hiding higher material markups compared to what you might achieve sourcing directly if you have the expertise and connections.

Read more:

Mastering key garment industry terminology is more than just learning jargon; it’s about empowering your clothing business. As this glossary demonstrates, understanding terms across design, sourcing, manufacturing, logistics, and costing allows for clearer communication throughout the complex fashion supply chain.

This clarity minimizes costly errors, builds stronger relationships with suppliers, streamlines your workflow, and ultimately contributes to smoother, more successful operations. Applying this apparel vocabulary consistently will enhance your credibility and efficiency.

Should you need specific guidance on sourcing high-quality, customized components like brand labels, care labels, hang tags, or specialized packaging solutions like poly mailers and zipper bags, the crucial next step is to ensure they meet your requirements while successfully navigating supplier MOQs.