What Is A Sewing Needle: Your Guide To Types, Sizes, Use

Choosing the right tools can make any craft easier and more enjoyable. This is very true for sewing! One of the smallest but most important tools is the sewing needle. This guide will help you understand everything about sewing needles.

1. Introduction: What exactly is a sewing needle?

1.1. Simple definition

A sewing needle is a small, thin tool used for sewing. Its main job is to make a small hole in fabric (or other material). It then pulls thread through that hole to create stitches, which join pieces of fabric or create decorations.

Most needles have two main parts. At one end, there is a sharp tip called a point. This point helps the needle go through the fabric. At the other end, there is a small hole called an eye. The eye holds the thread. Sewing needles are basic but very important sewing tools.

1.2. Why it’s good to know about needles

Using the right needle makes your sewing look better. It also makes the process easier for you. When you choose the correct needle:

- Your stitches will be neat and even.

- Your needle is less likely to break.

- Your thread won’t snap as often.

- You won’t damage your fabric. For example, you can avoid making holes that are too big or pulling threads.

Needles also get old or dull with use. Changing your needle regularly helps keep your stitches looking good. This highlights the importance of regular sewing needle replacement for stitch quality.

1.3. What you’ll learn here

In this guide, we will look at:

- The different parts of a sewing needle.

- The types of needles for sewing by hand.

- The types of needles for sewing machines.

- What needle sizes mean.

- How to choose the best needle for your project.

At Packlove, we help you with things like custom labels and bags for your amazing creations. We also want to help you understand the tools you use to make them, like sewing needles! Sewing needles are an important part of your textile equipment or sewing kit.

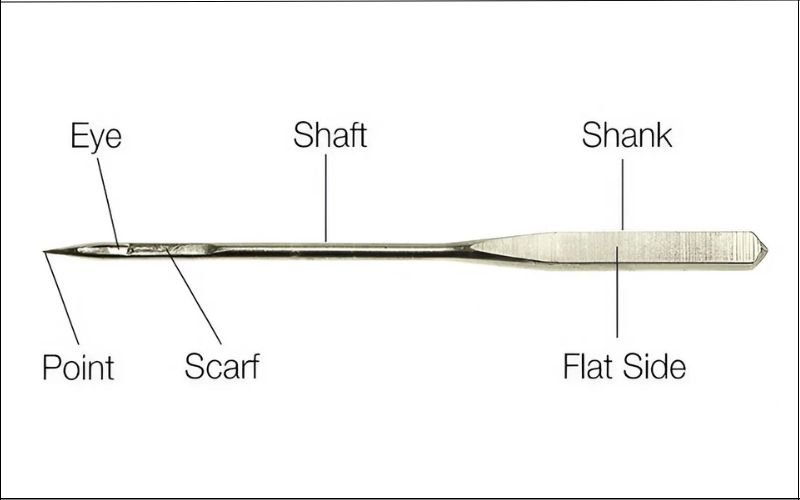

2. The building blocks: Parts of a sewing needle

2.1. Introduction to parts

Whether you sew by hand or with a machine, most needles have similar parts. Knowing these parts helps you understand how they work. It also helps you pick the right one for your sewing project. Let’s look at the different parts of a needle to understand their functions.

2.2. Key parts explained

Here are the main parts of a sewing needle:

- Shank: This is the top part of the needle. It’s the part that you hold if it’s a hand needle. For a machine needle, the shank is the part that fits into the sewing machine. The shank design is different for hand and machine needles. For machine needles, one side of the shank is usually flat. This flat side helps you put the needle into the machine the right way. Hand sewing needles usually have a round shank.

- Shaft: This is the long, main body of the needle. It goes from the shank down to the point. The thickness of the shaft is what determines the needle size number.

- Eye: The needle eye is the hole near the point of the needle. Its job is to hold the thread. The size of the eye needs to match the thickness of your thread. Thicker thread needs a bigger eye.

- Point: This is the very sharp tip of the needle. A sewing needle has a pointed tip. Its job is to pierce the fabric. Different needles have different point style or point type. These different points work best with different kinds of fabric. For example, a very sharp point is good for many fabrics. But a rounded ‘ballpoint’ is better for stretchy knit fabrics because it pushes the fabric threads aside instead of cutting them. Some needles have highly specialized point shapes engineered for specific fabric interactions, but common types cover most needs.

- Scarf: If you look closely at a sewing machine needle, you’ll see a groove or a small dip on one side, usually the back. This is called the scarf. It’s very important. It helps the machine’s hook catch the thread under the fabric to make a stitch.

2.3. Main differences (hand vs. machine summary)

So, the main things to remember are:

- Hand sewing needles are usually simpler. You hold them. They have a round shank and an eye for your thread.

- Sewing machine needles are made specially for machines. They have a flat-sided shank to fit correctly. They also have a scarf to help make stitches with the machine.

3. Needles for your hands: Exploring hand sewing needles

3.1. What are they?

A hand sewing needle is a needle you use to sew with your hands, without a sewing machine. These are the kind of garment needles people have used for a very long time. They are used for all sorts of sewing tasks, from fixing clothes to making beautiful decorations. This part of our guide will show you some common types in this guide.

3.2. Common types and their uses

Here are some common hand sewing needles and what they are used for:

Sharps: Sharps are common, all-purpose needles. They are medium length, have a round eye, and a sharp point. They are good for general sewing on many woven fabrics (fabrics that don’t stretch much, like cotton or linen). Sharp needles pierce woven fabrics cleanly.

Betweens (or Quilting Needles): These are shorter than Sharps. They have a small, round eye. Their short length makes them good for making small, even stitches. This is great for quilting.

Embroidery (or Crewel) Needles: These look like Sharps. However, they have a longer eye. This bigger eye makes it easier to thread thicker embroidery floss or yarn for embroidery.

Tapestry Needles: These have a large, long eye and a blunt (not sharp) point. They are used for needlepoint, cross-stitch, and sewing on fabrics with open weaves. Examples are canvas or Aida cloth. The needle passes the thread between existing fabric threads rather than piercing new holes.

Milliners (or Straw) Needles: These are long needles with a round eye. They are traditionally used in hat-making (millinery). They are also good for basting (temporary stitches) and some types of decorative stitching.

Other specialty hand needles (briefly):

- Darning needles: For mending holes, often with yarn. They are long with a large eye.

- Beading needles: Very fine and long, with a small eye, for stringing tiny beads.

- Leather Needles (or Glovers Needles): These have a wedge-shaped point (like a tiny chisel). This point is designed to cut through leather or similar tough materials without tearing them.

3.3. Quick tip for choosing

Here are two simple rules to help you choose a hand sewing needle:

- If your fabric is very fine and delicate, you usually need a finer (thinner) needle.

- If your thread is thick, you will need a needle with a bigger eye. This lets the thread pass through easily.

4. Needles for your machine: A look at sewing machine needles

4.1. What’s special?

Sewing machine needles are made just for sewing machines. They look different from hand needles. Remember the shank? On a machine needle, it has a flat side. This ensures it fits into the machine correctly, it has a flat side on its shank.

And they have that special groove called a scarf. The scarf helps the machine make perfect stitches. Let’s explore the sewing machine needle types explained so you know which one to pick for your machine.

4.2. Popular types and their uses

Here are popular machine needle types and their uses:

- Universal Needles: These needle types are a good starting point. They have a slightly rounded point. They can sew many types of woven fabrics and some stable knit fabrics. Universal needles are suitable for woven fabrics and many common projects.

- Ballpoint (or Jersey) Needles: These needle types have a more rounded tip. This is important for knit fabrics. The rounded point pushes the knit fibers apart instead of cutting them. This prevents holes or runs in your knit fabric. So, Ballpoint needles are designed for knit fabrics.

- Stretch Needles: For very stretchy fabrics like Lycra or swimwear fabric, you need needle types. These are designed to prevent skipped stitches on these tricky fabrics. This is key when choosing the correct sewing needle for stretch material. They often have a special eye and scarf.

- Sharps (or Microtex) Needles: These needle types have a very fine, sharp point. They are perfect for sewing straight lines on delicate, lightweight, or tightly woven fabrics like silk, microfiber, or for making sharp corners. They create very precise stitches.

- Jeans (or Denim) Needles: As the name says, these needle types are for heavy, dense fabrics like denim, canvas, or workwear. They have a strong, sharp point and a reinforced blade. This helps them go through thick layers without breaking.

- Leather Needles: For sewing leather, suede, or vinyl, you need special needle types. These have a wedge-shaped point, like a tiny chisel, special triangular or chisel/wedge point. This point cuts a clean hole in these non-woven materials.

- Embroidery Needles (Machine): If you’re doing machine embroidery, these needles have a wider eye. Sometimes they have a special scarf. This protects decorative embroidery threads from shredding or breaking. These are a type of embroidery needles for machines.

- Quilting Needles (Machine): These are designed to go through multiple layers of fabric and batting smoothly. They often have a slightly tapered point to help.

- Topstitching Needles: For topstitching where you want the stitches to be visible and decorative, these needles are great. They have an extra-large eye and a large groove in the shaft. This allows you to use thicker topstitching thread without it breaking.

4.3. What are twin or triple needles?

You might also see twin needles or triple needles. These are special needles that have two (twin) or three (triple) needles attached to a single shank. They are used on a sewing machine to sew two or three parallel rows of stitches at the same time. This is often used for hemming knit fabrics or for decorative stitching. These are rare features for most everyday sewing but good to know about.

4.4. A note on needle color codes

Some sewing machine needle brands use a color-coding system for type/size identification on the shank of the needle. This helps you quickly see what type or size it is. For example, a blue band might mean it’s a Jeans needle for one brand. However, not all brands use the same colors. So, it’s always best to read the package to be sure. This color system is a helpful feature from some makers, though not universally adopted.

5. What do those numbers mean? Understanding needle sizes

5.1. Why size matters

Choosing the right needle size is as important as choosing the right type. The correct size helps you get good stitches. It stops your thread or needle from breaking. It also keeps your fabric safe from damage, like holes that are too big. Clearly, needle size affects stitch formation. A good match between needle size, fabric, and thread is key. This section will help you with understanding sewing needle sizes for different fabrics.

5.2. Two main sizing systems

When you look at a package of sewing machine needles, you’ll usually see two numbers for the size, like 70/10 or 90/14. This is because there are two main sizing standards (European/NM and American/Singer).

- The first number (e.g., 70) is the European size, also called NM or metric size. These usually range from 60 to 120.

- The second number (e.g., 10) is the American (or Singer) size. These usually range from 8 to 20.

Both numbers on the package (e.g., 70/10 or 90/14) refer to the same single needle, representing a dual numbering system (European/American). For example, a needle labeled 80/12 is an 80 in European sizing and a 12 in American sizing. It’s just two ways of saying the same size. Understanding this helps you read any needle size chart.

5.3. General rule

The main thing to remember is:

- Smaller numbers (like 60/8 or 70/10) mean a finer, thinner needle.

- Larger numbers (like 100/16 or 110/18) mean a thicker, heavier needle.

5.4. Simple guide to matching size and fabric

Here’s a simple guide to help you match needle size to your fabric. This considers fabric weight and type (e.g., wovens, knits, delicates, heavy-duty).

- For fine or lightweight fabrics (like silk, chiffon, voile, very light cotton lawn): Use smaller sizes, e.g., 60/8, 65/9, 70/10, or 75/11.

- For medium-weight fabrics (like quilting cotton, linen, poplin, some knit fabrics): Use medium sizes, e.g., 80/12 or 90/14. This is often a good general-purpose range.

- For heavyweight fabrics (like denim, canvas, upholstery fabric, thick wool): Use larger sizes, e.g., 100/16, 110/18, or even 120/20 for very thick materials.

Remember, your thread thickness also matters. Finer threads work best with finer needles. Thicker threads need larger needles with bigger eyes.

Sewing Needle Guide

| Fabric Weight/Type | Example Fabrics | European Needle Size (NM) | American Needle Size |

|---|---|---|---|

| Fine/Lightweight | Silk, chiffon, voile | 60-75 | 8-11 |

| Medium-weight | Cotton, linen, poplin, light knits | 80-90 | 12-14 |

| Heavy-weight | Denim, canvas, upholstery | 100-120 | 16-20 |

6. Picking the perfect partner: How to choose the right sewing needle

6.1. Ask these questions

To choose the right needle, ask yourself these three main questions:

What fabric am I using?

This is usually the most important question. Is your fabric woven (doesn’t stretch much, like cotton sheets)? Is it a knit (stretchy, like t-shirt material)? Is it delicate (like silk)? Or is it heavy-duty (like denim)? Your fabric type primarily determines your needle choice. This will help you learn which needle is best for specific fabrics or sewing tasks.

What thread am I using?

Is your thread fine, all-purpose, or thick (like topstitching thread or embroidery floss)? The needle’s eye must be large enough for the thread to pass through easily. It should not shred or break the thread. This relates to thread compatibility. While this guide focuses on needles, remember that knowing how to choose appropriate thread for different needles and fabrics is also important for good results.

What kind of sewing am I doing?

Are you doing general sewing, like putting pieces together? Or are you doing something special like topstitching, embroidery, or quilting? Some sewing applications (e.g., general sewing, quilting, embroidery) have special needles designed just for them.

6.2. Simple steps to choose

Here’s a simple way to put it all together:

Step 1: Look at your fabric. Is it woven cotton? Stretchy jersey knit? Thick denim?

Step 2: Choose your needle type based on the fabric.

- For woven cotton: A Universal or Sharps/Microtex needle is good.

- For stretchy jersey knit: A Ballpoint or Stretch needle is best.

- For thick denim: A Jeans needle is what you need.

Step 3: Choose your needle size based on the fabric weight and your thread.

- For lightweight woven cotton with all-purpose thread: Try a 70/10 or 80/12.

- For medium-weight jersey knit with all-purpose thread: An 80/12 or 90/14 Ballpoint might be right.

- For heavy denim with strong thread: A 90/14 or 100/16 Jeans needle is a good start.

6.3. Always test!

Always test! Before you start sewing on your actual project, take a scrap piece of the same fabric and thread. Sew a few test stitches. This is the best way to see if your needle, thread, and machine settings are working well together. If the stitches look good and the fabric isn’t puckering or snagging, you’re ready to go!

7. Using and caring for your sewing needles

7.1. When to change your needle

It’s important to change your sewing machine needle regularly for the best stitch quality. A good rule is to change it after about 8 to 10 hours of sewing time. Or, change it before you start a big new project. This is a key part of the importance of regular sewing needle replacement for stitch quality.

Hand sewing needles last longer. But you should change them if they become bent, rusty, or dull (not sharp anymore).

This advice helps you find information on how to use and care for sewing needles.

7.2. Signs you need a new needle

Your sewing will often tell you when it’s time for a new needle! Look out for these signs:

- Skipped stitches (the machine misses some stitches)

- Thread breaking or shredding (getting fluffy)

- Fabric puckering (gathering up) or snagging (threads being pulled)

- A thumping or clicking sound as the needle goes into the fabric

- The needle has trouble going through the fabric.

7.3. Storing needles

Keep your needles organized and safe. You can store them:

- In their original packaging (so you know the type and size).

- In a pin cushion (especially hand needles).

- In a special needle case or organizer.

Good storage keeps them from getting lost or damaged. It also helps you find the right one easily. Needles are common haberdashery items or craft supplies you’ll want to keep track of.

8. Sewing needles and your custom projects

8.1. Attaching details

Hand sewing needles are perfect for adding those special finishing touches to your projects, such as sewing on woven labels, patches, or attaching strings to hang tags. They enable neat and precise label attachment.

8.2. Best needles for labels

For attaching woven labels by hand, we recommend using a fine, sharp hand sewing needle. A Sharps needle or a Milliner’s needle in a small size (like size 9, 10, or 11) usually works very well. These small needles make tiny holes. They help you create neat, almost invisible stitches.

8.3. Machine-sewing labels

If you prefer to machine-sew your labels or patches onto sturdy items, a Universal needle or a Sharps/Microtex needle in size 70/10 or 80/12 usually works well. Pair it with good quality all-purpose thread. This is suitable for most fabrics. Always test on a scrap first!

9. Frequently asked questions (FAQs)

9.1. What’s the best all-around needle for a beginner?

For machine sewing, a Universal needle in size 80/12 is a good start for many common woven fabrics. For hand sewing, a mixed pack of Sharps needles will cover many basic tasks.

9.2. Can I use a hand sewing needle in my sewing machine?

No, you should never use a hand sewing needle in a sewing machine. Machine needles have a special flat-sided shank (unlike the typically round shank of hand sewing needles), which is crucial for them to fit correctly and work with the machine’s mechanism. Using a hand needle could damage your machine.

9.3. What happens if I use the wrong needle size or type?

Using the wrong needle can cause problems like:

- Skipped stitches or uneven stitches.

- The thread breaking or shredding.

- The needle breaking.

- The fabric getting damaged (e.g., holes, puckers, snags).

9.4. How do I know if my needle is dull or damaged?

Signs of a dull or damaged needle include: difficulty pushing the needle through fabric, a popping or thumping sound when sewing, fabric snagging, skipped stitches, or shredded thread. If you suspect your needle is bad, it’s always best to change it.

Read more:

So, now you know much more about sewing needles! Remember these key things:

- Needles have different parts, and understanding them helps.

- There are many types of needles for hand sewing and machine sewing, each for different jobs.

- Needle sizes are important – match the needle size to your fabric and thread.

- Choosing the right needle makes your sewing easier and your projects look great!

The best way to learn is to try! Don’t be afraid to experiment with different needles on scrap fabric. See what works best for you. Happy sewing! Visit MyPackLove.com for all your custom packaging, labels, and branding needs to make your creations shine! Want more helpful tips for your projects? Explore more guides on the Packlove blog!