What is Warp: Simple Definition And Its Role in Woven Labels

Ever wondered what holds a piece of fabric together? Or what makes your custom woven labels look sharp and last long? A big part of the answer lies in something called “warp” threads. Understanding warp is simpler than you think, and it’s key to making smart choices for your branding needs.

This article will simply explain what warp is and why it’s so important, especially for products like custom woven labels. At Packlove, we believe that a little knowledge can go a long way in creating the perfect branding materials. Let us be your helpful guide.

1. What exactly is warp?

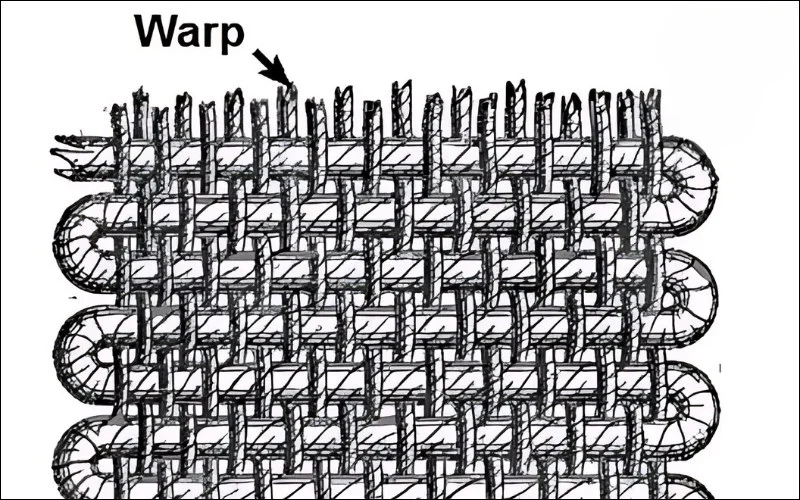

So, what is warp? Imagine you’re about to weave a piece of fabric on a weaving loom (a frame or machine used for weaving). The warp threads are the first set of threads you put in place. These threads run up and down, or lengthwise threads in fabric.

Think of warp yarns this way: they are like the skeleton or the backbone of the fabric. They are set up on the loom under tension, ready for other threads to be woven through them. These warp threads form the foundation of woven fabric. This makes them essential fabric construction elements in all textile weaving.

Key things to remember about warp threads:

- They run lengthwise (up and down the fabric).

- They are set up first on the weaving loom.

- They form the fabric’s foundation.

- They are held tight (under tension).

2. Understanding weft: warp’s counterpart

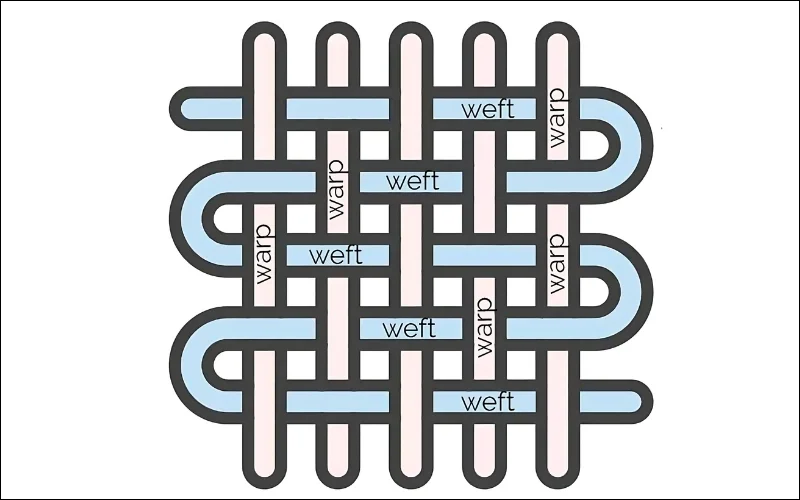

Now that you know about warp, let’s meet its partner: “weft” threads. If warp threads run lengthwise (or longitudinally), weft threads run sideways. They go from one side of the fabric to the other, across the warp threads. These are also called crosswise threads.

The magic happens when warp and weft come together. The weft threads are woven over and under the warp threads, again and again. This interlacing process is what creates the fabric itself.

Think of it like graph paper:

- Warp threads are the vertical lines.

- Weft threads are the horizontal lines.

Together, they make the grid – or in this case, the fabric.

This combination is crucial for understanding warp and weft in woven labels. The difference between warp and weft threads in textiles is their direction and job: warp provides the base, and weft fills in the pattern and body. Yes, woven labels utilize warp and weft interlacing to create those detailed designs you love. A woven label (a label made by weaving threads together, often found on clothing necklines or seams) is a perfect example of this.

3. Why is warp so important? its role in weaving and fabric quality

Warp threads do more than just sit there. They play a huge role in how strong a fabric is and how it looks and feels.

3.1 Warp provides strength and structure

One of the main jobs of warp threads is to give the fabric its strength. Remember how warp threads are held tight on the loom? This thread tension is important. The loom holds warp threads under tension throughout the weaving process.

Because they are stretched tight and form the base, warp threads act as the fabric’s backbone. This makes the fabric strong and durable. Warp, as a structural element of the fabric, is what helps it withstand pulling and wear. This shows the importance of warp threads in fabric quality; a strong warp means a fabric that lasts.

3.2 Warp influences fabric look and feel

The warp also affects how your fabric, and specifically your woven labels, will look and feel.

- Warp material: The type of yarn used for the warp threads can change the fabric. Common materials include cotton yarn or polyester yarn. For many labels, polyester as a warp yarn material is popular because it is strong and holds up well. Different materials give different feels – cotton might be softer, while polyester offers more strength.

- Warp density (warp count): This simply means how many warp threads are packed into a certain space, like an inch or a centimeter. This is related to the overall thread count of a fabric. To explain warp count for custom labels: a higher warp count (more threads packed closely together) means that warp density influences label detail significantly. If you want small text or very detailed logos on your woven labels, a higher warp density is better. This is how warp affects woven label detail.

At Packlove, we’ve seen that using high-density warp for intricate designs makes logos and text much clearer and sharper. Our clients are often very happy with the improved sharpness when we recommend a higher warp density for their detailed artwork.

3.3 Warp in woven labels from Packlove

At Packlove, we understand how warp quality affects woven label sharpness. Good quality warp yarns are essential for creating crisp, clear designs in woven label production. We’ve fulfilled many orders where choosing the right warp density turned a good design into an amazing, professional-looking label.

Good warp also means your labels will be more durable. They will resist fraying and last longer on your products. Packlove focuses on offering woven labels with durable, high-quality warp yarns to ensure your brand looks its best.

4. How is warp used in the weaving process?

The weaving process might sound complex, but the basic role of warp is straightforward. Here’s a very simple overview:

- Setting up the loom: The very first step is setting up the warp on the loom. This means arranging all the warp threads on the weaving loom. They must be straight, parallel, and held under even tension.

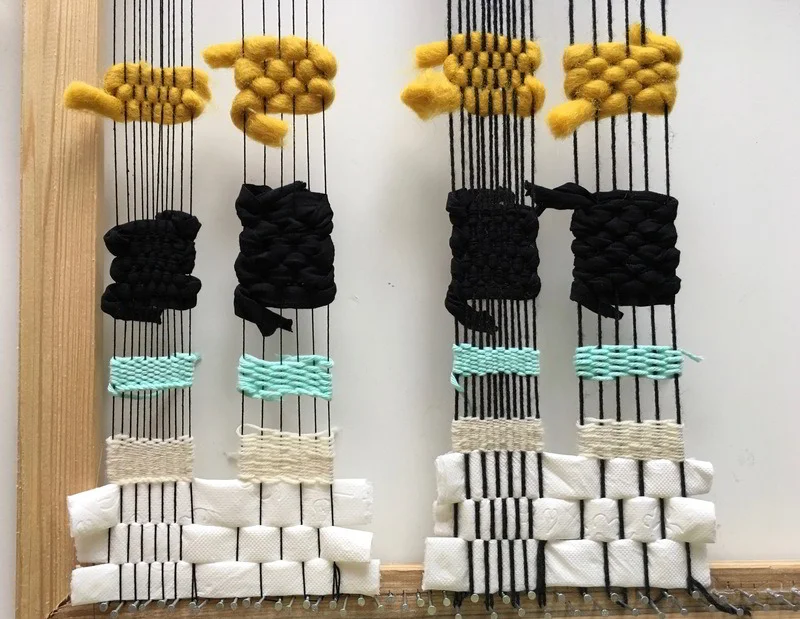

- The weaving action: Once the warp is ready, the weft threads are passed over and under the warp threads. This is usually done with a shuttle or other mechanism.

- Different weave structures: By changing the pattern of how the weft goes over and under the warp, different weave structures are made. This creates different fabric textures and appearances. For example, a damask weave (a patterned weave that creates reversible designs, often with a satin-like finish) is a common weave structure for labels because it’s great for showing fine details. The warp is the foundation for all these patterns.

5. Choosing the right warp for your needs

When you’re ordering custom woven labels, thinking about the warp can help you get the best results.

- Design consideration: If your label design has very small letters, tiny details, or intricate lines, a higher warp density will likely be needed to make it look clear. Packlove offers consultation on choosing the best warp characteristics for specific label designs. From our experience, we often advise clients to slightly simplify very complex designs if a standard warp density is preferred for budget reasons. Otherwise, we recommend opting for a higher density. We can even show examples of what works best for different design complexities.

- Usage consideration: Think about where your label will be used. A label for sturdy work clothes might benefit from a stronger warp, while a label for a soft baby blanket might use a standard, softer option.

Packlove’s guidance:

Our standard warp material is typically polyester yarn because it’s strong, durable, and holds detail well for polyester warp labels. For warp color, it’s usually a base color that gets mostly covered by the weft threads (which create your design’s colors).

While special options like multi-color warp setup or even metallic warp yarns exist, these are rare attributes and not standard for most label orders.

Interested in eco-friendly options? You can ask us about the possibility of using recycled polyester warp threads. We always strive to meet our clients’ needs and can explore this for your project.

6. Frequently asked questions (FAQs) about warp

Here are some common questions people ask about warp:

6.1 Is warp always stronger than weft?

Usually, yes. Warp threads are held under tension during weaving and form the backbone of the fabric, so they are generally made to be stronger. This is a key piece of basic textile knowledge for branding materials.

6.2 Can the color of the warp threads affect my woven label’s design?

Sometimes it can, especially if you have a light-colored design or if the weft threads don’t cover the warp completely. Mostly, the weft threads create the main colors you see. This is related to how thread count impacts label design. At Packlove, this is a common concern. We typically use a neutral-colored warp (like white or black) or a warp color that blends well with your design’s main weft colors to minimize any show-through.

6.3 What is “warp-faced” fabric?

A “warp-faced” fabric is one where the warp threads are more visible on the surface of the fabric than the weft threads. This contrasts with “weft-faced” fabric, where the weft is more prominent. This helps in understanding weft threads in weaving and their visibility.

6.4 How do I know what warp is best for my custom labels?

The best way is to talk to us at Packlove! We can help you choose based on your specific design, how the label will be used, and your budget. Understanding warp is important for custom label design. While you can research basic weaving terms for custom label production, our team is here to guide you.

Read more:

So, there you have it! Warp threads are the strong, lengthwise threads that form the foundation of woven fabrics, including your custom woven labels. They are a critical woven label component, and warp threads are essential for quality.

Understanding a little about warp helps you make better choices and appreciate the quality of your custom branding products. At Packlove, we’re passionate about helping you create items that perfectly represent your brand. We hope this guide makes the world of weaving a little less mysterious. Ready to create high-quality custom woven labels? Explore Packlove’s options or contact us for expert advice!