Woven vs Embroidered Patches: Choosing the Right Custom Patch

Custom patches offer a powerful way to personalize apparel, build brand identity, and create a sense of belonging. However, with a variety of patch types available, choosing the right one for your project can feel overwhelming. This guide focuses on two popular options: woven and embroidered patches.

We’ll delve into the distinct characteristics of each, exploring their advantages, disadvantages, and ideal applications. By understanding the nuances of woven versus embroidered patches, you’ll be empowered to make an informed decision that aligns with your design vision, budget, and intended use, ultimately saving you time and ensuring a successful outcome.

Furthermore, we’ll introduce you to Packlove’s custom patch services, simplifying the process of bringing your unique patch designs to life.

1. Woven vs. embroidered patches: What’s the difference?

1.1 Understanding woven patches

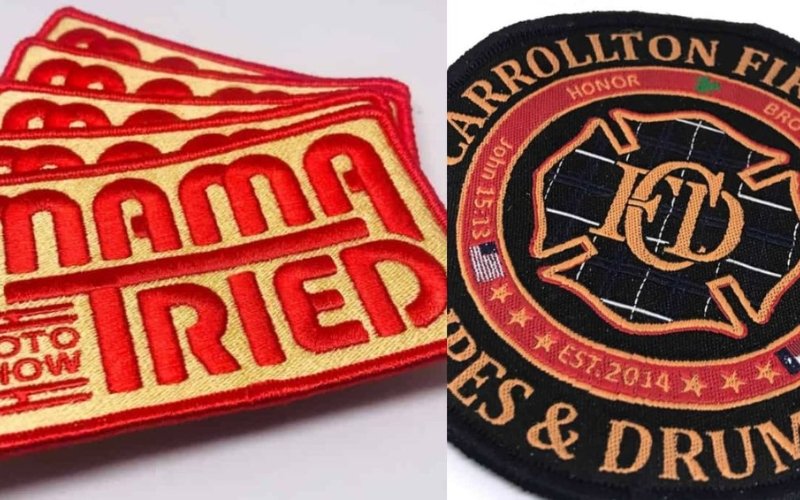

Woven patches are created by interlacing threads of varying colors to form the design directly within the fabric. This process, akin to weaving a miniature tapestry, results in a tight weave that yields a smooth, flat surface without any raised threads.

This technique creates a sleek and modern aesthetic, often less bulky than embroidered patches. Woven patches are particularly well-suited for intricate designs, small text, and smooth gradients, as the weaving process allows for cleaner lines and more precise color transitions.

They are an excellent choice for rendering logos with fine details and achieving subtle shading effects. Commonly used materials include polyester, twill, and damask, chosen for their durability and ability to showcase fine detail.

1.2 Exploring embroidered patches

Embroidered patches, on the other hand, are crafted by stitching thick threads onto a fabric backing, building the design on top of the base material. This method produces a classic, textured, 3D look with raised threads, lending a traditional, handcrafted feel to the patch.

Embroidered patches are ideal for bold, striking designs with larger elements, where the visual impact is prioritized over extremely fine detail. While they can accommodate a range of colors, the transitions between colors may be less smooth compared to woven patches.

Common materials for the backing include cotton, felt, and twill, which contribute to the patch’s overall thickness and texture. Creating an embroidered patch involves digitizing the design, which means converting it into a format that embroidery machines can read and execute.

1.3 Woven vs. Embroidered Patches: A Head-to-Head Comparison

| Feature | Woven Patches | Embroidered Patches |

| Appearance | Flat, smooth | Raised, textured |

| Texture | Smooth | Textured |

| Detail | Highly intricate, fine lines, small text | Bold, larger elements, less intricate detail |

| Durability | Good | Excellent |

| Cost | Generally lower | Generally higher |

| Production Time | Faster | Slower |

| Best Uses | Detailed logos, small text, gradients | Bold designs, uniforms, classic look |

This table provides a concise comparison of woven and embroidered patches, highlighting their key differences. Woven patches offer a smooth, flat appearance, making them ideal for intricate designs and detailed logos, while embroidered patches provide a textured, raised look, perfect for bold designs and a classic aesthetic.

While both types are durable, embroidered patches are often considered more so due to their thicker construction. However, woven patches are generally more cost-effective and have a faster production time.

2. Choosing the right patch for your needs

2.1 Design considerations

The complexity of your design is a crucial factor in choosing between woven and embroidered patches. For highly detailed designs that incorporate small text or subtle color gradients, woven patches are often the better choice.

Their tight weave allows for precise rendering of intricate elements and smooth transitions between colors. Conversely, if your design is simpler and bolder, emphasizing visual impact over minute details, an embroidered patch might be more suitable.

The textured, raised surface of embroidered patches enhances the visual appeal of simpler designs and adds a tactile dimension. Consider how your logo or artwork will translate to each patch type, taking into account size limitations and the need for scalability.

2.2 Budget and turnaround time

Cost and production time are practical considerations that can influence your decision. Woven patches are generally more cost-effective, primarily because their production process is faster and requires less labor compared to embroidery.

This makes them an attractive option for budget-conscious projects or large orders. Embroidered patches, with their intricate stitching and handcrafted feel, tend to be more expensive due to the more labor-intensive process.

The size, quantity, and complexity of the design also impact the final cost for both types. Woven patches generally have a quicker turnaround time, while embroidered patches may require more time to produce, especially for large orders. If you’re considering a large order, inquire about bulk discounts.

2.3 Application and Care

Custom patches come with various backing options, each with its own advantages. Iron-on patches offer easy application with a heat press or household iron, making them convenient for quick attachment. Sew-on patches provide the most permanent and durable attachment, ideal for items that undergo frequent washing or heavy use.

Adhesive backings are suitable for temporary use or for attaching patches to surfaces other than fabric. Velcro patches offer the flexibility of easy removal and reattachment, perfect for interchangeable designs or uniforms. Proper care is essential to maintain the longevity of your patches. Generally, it’s recommended to wash garments with patches inside out, using a gentle cycle and avoiding harsh chemicals or bleach.

3. FAQs about Custom Patches

3.1 What is the minimum order quantity for custom patches?

At Packlove, the minimum order quantity for custom patches varies depending on the type of patch and the complexity of the design. Generally, we strive to accommodate both small and large orders. It’s always best to contact us directly to discuss your specific requirements, as we may be able to offer custom arrangements or exceptions to the standard minimums.

3.2 How long does it take to receive my custom patches?

The turnaround time for custom patches depends on several factors, including the type of patch, the complexity of the design, the order quantity, and our current production schedule. Woven patches typically have a faster production time than embroidered patches.

Once your order is placed and the design is finalized, we can provide you with a more accurate estimate. Generally, you can expect your order to be completed and shipped within 2-4 weeks.

3.3 What file formats do you accept for patch designs?

We accept a variety of file formats for custom patch designs, including .ai, .eps, .pdf, and high-resolution .jpg files. Ideally, vector files (.ai or .eps) are preferred as they allow for the best quality and scalability. Regardless of the file format, it’s crucial to ensure that your artwork is high-resolution to ensure the best possible outcome for your custom patches.

3.4 Can I request a sample of my patch before placing a large order?

Yes, Packlove understands the importance of seeing a physical sample before committing to a large order. We offer the option to request a sample of your patch for a nominal fee. This allows you to assess the quality, colors, and overall appearance of the patch before proceeding with full production. The process for requesting a sample can be discussed with our team.

3.5 What are the different backing options available for custom patches?

Packlove offers a variety of backing options to suit different needs and applications. Iron-on backings provide a convenient way to attach patches using heat. Sew-on backings offer the most permanent attachment, ideal for items that will be washed frequently.

Adhesive backings are great for temporary applications or attaching patches to non-fabric surfaces. Velcro backings allow for easy removal and reattachment, perfect for interchangeable designs. Choosing the right backing depends on how the patch will be used and the desired level of permanence.

4. Packlove – Providing services for custom patches

Packlove is a premier provider of high-quality custom patches, specializing in both woven and embroidered options. We are dedicated to creating personalized patches that meet the diverse needs of our clients, from individual crafters to large organizations.

Our Value Booster Kit is a great way for customers to explore different patch types and customization possibilities. We also offer a range of other branding solutions, including Woven Labels for a professional touch on apparel, Heat Transfer Labels for easy application, and custom Zipper Bags for unique packaging.

To bring your custom patch vision to life, visit our website at https://mypacklove.com/. Our team is ready to provide you with a free quote and expert guidance throughout the design and ordering process.

Read more:

Choosing between woven and embroidered patches depends on a variety of factors, including the complexity of your design, your budget, the desired aesthetic, and the intended application. Woven patches excel in rendering intricate details and smooth gradients, while embroidered patches offer a classic, textured look ideal for bolder designs. Understanding these distinctions is crucial for making informed decisions when creating custom patches. Packlove offers a wide range of custom patch options, along with personalized guidance and support, to help you bring your unique vision to life. Let us help you create the perfect custom patches for your needs.