How to print on poly mailers: Methods, costs and eco-friendly options

Tired of your packaging blending in with the crowd? Generic poly mailers are a missed opportunity to connect with your customers and elevate your brand. This comprehensive guide breaks down the essentials of printing on poly mailers, helping you navigate the various printing methods, design choices, and eco-friendly options available. Whether you’re struggling with high printing costs or simply unsure where to begin, this article equips you with the knowledge to create personalized packaging that strengthens your brand identity, resonates with your target audience, and maximizes your investment.

1. Understanding poly mailers and the benefits of printing

1.1 What are poly mailers?

Constructed from polyethylene (PE), poly mailers offer a lightweight yet durable packaging solution. This material provides inherent moisture resistance, safeguarding contents from the elements. Available in a range of standard sizes, poly mailers can also be custom-manufactured to meet specific dimensional needs. While typically found in white or gray, they offer the versatility of custom color printing for branding and aesthetic enhancement.

1.2 Why print on poly mailers?

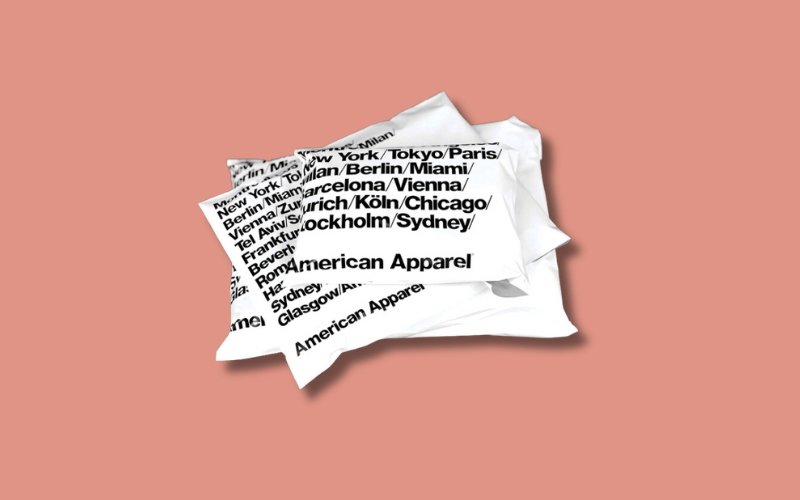

Printing on poly mailers transforms them from simple shipping necessities into powerful marketing tools. Custom poly mailers, emblazoned with your logo and branding, significantly increase brand recognition and foster a memorable customer experience. Studies show that packaging plays a crucial role in purchasing decisions, with a significant percentage of consumers more likely to remember and recommend brands with attractive packaging.

Branded poly mailers contribute to a positive unboxing experience, creating a sense of anticipation and excitement that elevates your brand perception. Beyond aesthetics, printed poly mailers, particularly with personalized touches, enhance your professional image and even reduce shipping errors thanks to clear and prominent branding. Investing in custom packaging, such as branded and personalized poly mailers, is a strategic move for any online business seeking to optimize its e-commerce shipping and leave a lasting impression.

2. Printing methods for poly mailers

2.1 Digital printing (Inkjet/Thermal)

For smaller printing runs of custom poly mailers, inkjet printing can be a viable option. This involves using a specialized handheld inkjet printer, rather than a standard desktop printer, to apply the design directly onto the mailer. However, this method may not be suitable for highly detailed images or complex designs due to the limitations of the technology. Simpler graphics and text-based designs are generally better suited for handheld inkjet printing on poly mailers.

2.2 Screen printing

Screen printing offers another alternative for smaller quantities of custom poly mailers. Similar to textile screen printing, this method involves placing the mailer on a flat platen to secure it during the process. A screen containing the desired design is positioned over the poly mailer, and ink is then pulled across the screen using a squeegee, transferring the image. While effective for limited runs, screen printing on poly mailers has limitations regarding the number of colors achievable and requires printing each bag individually, making it less efficient for large-scale production.

2.3 Flexographic printing

Flexography stands as a prominent printing method for poly mailers and plastic shipping bags. This technique shares similarities with letterpress printing but utilizes flexible relief plates instead of rigid ones. In the flexographic process, large rolls of plastic film are fed through a web press. As the flexible printing plate rotates on a roller, it applies the ink to the plastic film, creating the desired print. The printed film is then rewound. A subsequent pass through the heat press seals and cuts the film, forming the finished poly mailer bags. This efficient process is well-suited for high-volume production.

2.4 Choosing the right printing method

Choosing the right printing method for your poly mailers depends on a variety of factors, including order volume, budget, design intricacy, and desired turnaround time. The following table provides a comparative overview to help you make an informed decision:

| Feature | Inkjet (Handheld) | Screen Printing | Flexography |

| Order Quantity | Low | Low | High |

| Cost per Unit | Moderate | High | Low |

| Design Complexity | Low | Moderate | High |

| Print Quality | Moderate | High | High |

| Turnaround Time | Fast | Moderate | Moderate |

| Sustainability | Moderate | Moderate | Moderate |

Making the Right Choice:

- Low Quantities, Simple Designs, Fast Turnaround: Handheld inkjet printing offers a practical solution for small businesses or those needing quick, personalized packaging for limited promotions.

- Low Quantities, High-Quality Designs: Screen printing provides excellent print quality for detailed designs when order quantities are low, but it comes at a higher cost per unit.

- High Quantities, Complex Designs, Cost-Effectiveness: Flexography is the ideal choice for large production runs, intricate designs, and achieving the lowest cost per unit. While the initial setup might be more involved, the efficiency and affordability for bulk orders make it the most economical option.

Consider your specific needs and priorities when selecting a printing method. If quality and intricate designs are paramount and your order volume is low, screen printing may be the best option. However, for high-volume orders where cost-effectiveness is key, flexography is the clear winner. For small businesses just starting out and needing limited quantities quickly, handheld inkjet printing offers a good entry point. By carefully evaluating these factors, you can select the best method for printing logos and designs on your poly mailers, ensuring high-quality, functional, and cost-effective packaging.

3. Designing your poly mailer prints

3.1 Software and design tips

Creating compelling designs for your poly mailers is easier than you think, even without advanced design skills. User-friendly software like Canva offers intuitive interfaces and pre-designed templates to get you started quickly. For more complex designs and professional-grade results, Adobe Illustrator provides powerful vector editing capabilities.

Here are some practical tips for designing effective poly mailers:

- Logo Placement: Position your logo prominently, typically centered or in the top corner, ensuring it’s clearly visible upon first glance.

- Color Schemes: Choose colors that align with your brand identity. Maintain consistency with your website and other marketing materials for a cohesive brand experience.

- Brand Messaging: Incorporate concise and impactful brand messaging. A short tagline or a call to action can enhance customer engagement.

- High-Resolution Images: Use high-resolution images (300 dpi or higher) to ensure sharp, professional-looking prints. Avoid pixelated or blurry images that detract from your brand image.

- Design for Printing: Keep in mind the chosen printing method and its limitations. Simpler designs often work best for methods like handheld inkjet printing, while flexography allows for more complex visuals.

By following these design tips and utilizing readily available software, you can create visually appealing and effective poly mailer designs that reinforce your branding and enhance the customer experience. Remember, your poly mailer is often the first physical touchpoint a customer has with your brand, so make it count!

3.2 Working with a printing company

Partnering with a reputable printing company specializing in poly mailers streamlines the production process and ensures high-quality results. Here’s a step-by-step guide to finding and collaborating effectively with a printing partner:

- Finding a printing company: Search online for “custom poly mailer printing” or “packaging companies specializing in poly mailers.” Look for companies with experience in the type of printing you require (flexographic, screen printing, etc.) and positive customer reviews.

- Requesting Quotes: Contact several printing companies and provide details about your project, including desired quantity, poly mailer size and material, printing method, and design complexity. Requesting multiple quotes allows for price comparison and ensures you’re getting the best value.

- Providing Print-Ready Files: Supply your chosen printing company with print-ready design files in the correct format (typically vector files like AI or PDF). Confirm the required specifications with the printer beforehand to avoid any compatibility issues.

- Proofing the Design: Before mass production, carefully review a digital or physical proof of your design. This crucial step allows you to catch any errors and ensure the final product meets your expectations. Don’t hesitate to request revisions if necessary.

- Understanding Finishing Options: Discuss finishing options with printing company. These might include adding a glossy or matte finish, incorporating tear-resistant perforations, or applying a tamper-evident seal.

By following these steps and communicating effectively with your chosen printing company, you can ensure a smooth and successful production process, resulting in high-quality, custom-printed poly mailers that represent your brand effectively.

4. Sustainable poly mailer printing

4.1 Eco-friendly materials and Inks

Modern brands must prioritize sustainable packaging practices to minimize their environmental footprint. Moving away from virgin plastics and non-renewable materials, businesses are increasingly adopting eco-friendly alternatives such as recycled poly mailers. These mailers utilize existing materials, reducing reliance on new resources, and are designed for recyclability after use. Companies like Mypacklove offer custom-printed recycled poly mailers, utilizing eco-friendly inks that don’t compromise recyclability. Furthermore, features like a second adhesive strip promote reuse, further diverting waste from landfills and extending the lifespan of the packaging.

4.2 Reducing waste and promoting reuse

Minimizing packaging waste is a crucial step towards environmental responsibility. Implementing practical strategies can significantly reduce your impact and promote a more sustainable approach. Incorporating double adhesive strips on poly mailers facilitates reuse, allowing customers to repurpose the packaging for returns or other shipping needs. Clearly communicating proper disposal and recycling practices through on-package messaging empowers customers to participate in the recycling process.

Furthermore, evaluating your overall packaging consumption and identifying opportunities to reduce material usage, such as right-sizing your poly mailers to minimize excess material, contributes to a more eco-conscious approach. By embracing these strategies, businesses can actively reduce waste, promote reuse, and foster a more sustainable packaging lifecycle.

5. FAQs about how to print on poly mailers

5.1 Can I print on poly mailers at home?

While printing on poly mailers at home is possible for small batches and personalized items, it’s important to understand the limitations. Inkjet printers, using specific durable inks designed for non-porous surfaces, can be used for basic designs and text. Thermal printers offer another option, especially for shipping labels and barcodes directly onto the mailer. However, home printing methods often lack the professional quality, durability, and cost-effectiveness of commercial printing for larger quantities. For small-scale projects or personalized touches, readily available inkjet printers with pigment-based inks or thermal label printers can be suitable. However, for high-volume or complex designs, professional printing services are recommended.

5.2 What is the most cost-effective printing method for large quantities?

For large quantities of printed poly mailers, flexographic printing emerges as the most cost-effective method. Compared to other large-scale options like rotogravure or offset printing, flexography offers several advantages:

- Lower Setup Costs: While flexography involves some initial setup costs for creating the printing plates, these are generally lower than the complex cylinder engraving required for rotogravure.

- High-Speed Production: Flexographic printing is a high-speed process, making it incredibly efficient for producing large volumes of poly mailers quickly.

- Material Compatibility: Flexography excels at printing on flexible substrates like polyethylene, making it ideally suited for poly mailers.

- Complex Designs: Modern flexographic printing can handle intricate designs, including halftones and gradients, with high fidelity.

While minimum order quantities might be higher for flexography, the cost savings per unit, combined with the efficiency and design capabilities, make it the most economical choice for large-scale poly mailer printing projects. Consider your specific needs and budget, but if volume and cost-effectiveness are priorities, flexography is likely the optimal solution.

5.3 How can I ensure my poly mailer design is print-ready?

Ensuring your poly mailer design is print-ready is crucial for achieving professional, high-quality results. Here are some essential tips for preparing your files:

- File Format: Use vector file formats like Adobe Illustrator (AI) or Encapsulated PostScript (EPS). These formats ensure your design remains sharp and scalable, regardless of size. Avoid using raster formats like JPEG or PNG, as they can pixelate when enlarged.

- Resolution: Use a resolution of 300 DPI (dots per inch) for all images and graphics. This resolution ensures your visuals are crisp and clear in the final print.

- Color Mode: Use CMYK (Cyan, Magenta, Yellow, Key/Black) color mode. This color mode is specifically designed for printing and ensures accurate color representation. Avoid using RGB (Red, Green, Blue), which is used for digital displays and can result in color discrepancies when printed.

- Outline Fonts: Convert all text to outlines or paths. This step ensures your chosen fonts are embedded in the file and prevents font substitution issues during printing.

Read more:

- Are poly mailers recyclable? A complete guide

- Shipping with poly mailers: Guide to sizes, types & benefits

- How to make custom poly mailers: Design, print & order

- Best poly mailers for Poshmark: Size, tips and where to buy

Custom-printed poly mailers offer a powerful opportunity to elevate your brand, enhance the customer experience, and promote sustainability. By understanding the various printing methods, from handheld inkjet for small batches to flexography for large-scale production, you can choose the optimal solution for your business needs. Prioritize eco-friendly practices by opting for recycled materials and promoting reuse. Invest time in creating compelling designs that reflect your brand identity and resonate with your target audience. Remember, your packaging is an extension of your brand, and a well-designed poly mailer can create a memorable unboxing experience that fosters customer loyalty and sets your business apart. By carefully considering your printing options and design choices, you can transform your packaging into a powerful marketing asset.