How to Write on Poly Mailers: Pens, Labels and Printing Guide

Poly mailers have become a staple of modern shipping, offering a lightweight, durable, and cost-effective solution for transporting a wide range of goods. However, ensuring that your poly mailers are properly addressed and labeled is crucial for successful delivery and maintaining a professional image.

This article serves as a comprehensive guide to the various methods for writing on and customizing poly mailers. Whether you’re an e-commerce business owner, an individual sending a gift, or simply someone who wants to ensure their packages arrive safely and look their best, this guide will equip you with the knowledge to optimize your shipping process and enhance your brand.

From choosing the right writing tools to exploring creative customization options, we’ll cover everything you need to know to confidently address and personalize your poly mailers.

1. Methods for addressing and labeling poly mailers

1.1 Handwriting on poly mailers

Handwriting directly on poly mailers is a simple, readily available method, but it requires careful attention to detail. The most crucial element is using a permanent marker with smear-proof and waterproof ink. This ensures that the address remains legible throughout the shipping process, even when exposed to moisture or handling.

When addressing the mailer, legibility is paramount. Write clearly and neatly, using a standard address format with the recipient’s name, street address, city, state, and zip code. Position the address centrally on the mailer for optimal visibility. While this method is cost-effective for individual shipments, it can become time-consuming for larger volumes.

1.2 Using pre-printed labels

Pre-printed labels offer a more professional and efficient solution for addressing poly mailers. These labels can be created using label-making software or online shipping platforms, allowing for consistent formatting and easy customization.

Choose label sizes that fit comfortably on your mailers and consider weatherproof, durable materials for added protection. When placing labels, ensure they are positioned squarely on the mailer’s surface, away from edges and seams, to facilitate smooth scanning by postal equipment.

If using non-adhesive labels, secure them completely with transparent packing tape, being careful not to obscure any barcodes or essential information. Properly applied labels enhance readability and contribute to efficient processing.

1.3 Direct printing on poly mailers

Direct thermal printing or thermal transfer printing directly onto poly mailers offers the highest level of efficiency, particularly for businesses handling large shipping volumes. This method requires specialized printers and compatible software designed for printing on flexible materials.

While the initial investment in equipment can be significant, the long-term benefits include streamlined operations and reduced labor costs. Direct printing also allows for on-demand customization and variable data printing, such as unique tracking numbers or recipient addresses. Alternatively, consider pre-printed custom poly mailers that feature your brand logo and other design elements for a professional and cohesive look.

2. Customizing poly mailers with logos and branding

2.1 Inkjet printing for poly mailers

Inkjet printing can be used for customizing poly mailers, particularly for smaller quantities or designs requiring full-color detail, such as intricate logos or vibrant artwork. It’s essential to use UV-curable inks, which are designed to adhere to non-porous surfaces like plastic and provide excellent durability against fading or smearing.

Inkjet printing provides a high degree of design flexibility, enabling businesses to create unique and eye-catching packaging.

2.2 Screen printing for poly mailers

Screen printing is a versatile and durable method for adding logos and designs to poly mailers. This technique involves creating a mesh screen stencil for each color in the design. Ink is then forced through the screen onto the mailer’s surface.

Screen printing is an excellent choice for bold, graphic designs with solid colors. It’s also suitable for larger quantities, as the setup process becomes more cost-effective with increased volume. Screen printing allows for good color matching, often referencing the Pantone Matching System (PMS) to maintain brand consistency.

2.3 Flexographic printing for poly mailers

Flexographic printing is a high-speed printing method that utilizes flexible printing plates and typically fast-drying, low-viscosity inks, which can be water-based, solvent-based, or UV-curable. It’s a highly efficient and cost-effective solution for large-volume orders of poly mailers. Flexographic printing excels at reproducing simple designs with one or two colors.

However, it may not be the best choice for intricate designs or those requiring a wide color gamut. The rapid printing process makes it ideal for businesses with high-volume shipping needs.

2.4 Offset printing for poly mailers

Offset printing is known for producing high-definition images and is an excellent choice for detailed designs on poly mailers. This method is typically used for very large print runs due to the setup involved. Offset printing delivers exceptional print quality, making it suitable for intricate logos, photographs, or complex artwork. It’s often the preferred method for achieving the highest level of visual detail and color accuracy.

3. Choosing the right poly mailer material and size

3.1 Understanding poly mailer sizes and dimensions

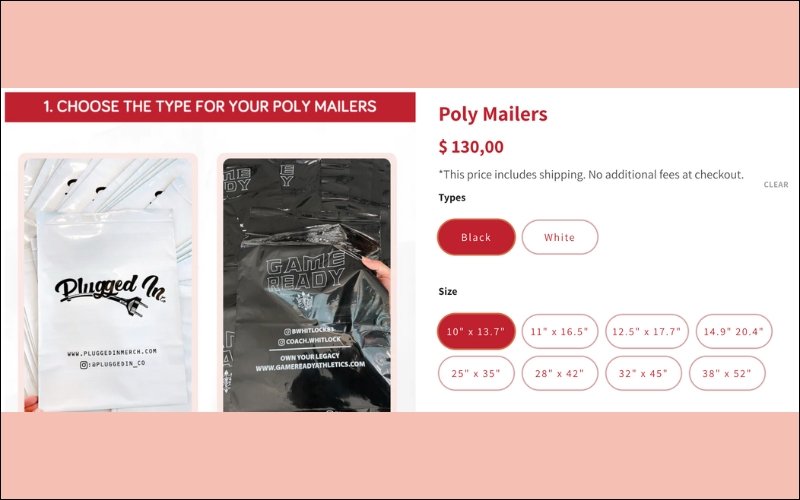

Selecting the appropriate poly mailer size is crucial for both protection and cost-effectiveness. Measure the dimensions of the product you’re shipping, adding extra space for cushioning if needed. Poly mailers come in a wide range of standard sizes. A good rule of thumb is to choose a mailer that’s slightly larger than your product to allow for easy insertion and sealing.

3.2 Selecting the right material for your needs

Poly mailers are typically made from polyethylene (PE) or polypropylene (PP), a durable and water-resistant plastic. The thickness of the mailer is measured in mils, with a higher mil count indicating a thicker, more robust material. For lightweight items like clothing, a lower mil thickness may suffice.

However, for heavier or more delicate items, a higher mil thickness is recommended for added protection against tearing and puncturing. In addition to thickness, consider the material’s opacity. Opaque mailers are essential for ensuring the privacy of the contents.

Moreover, for businesses seeking eco-conscious options, there are now poly mailers available that are made from biodegradable, compostable, or recycled materials, helping to minimize environmental impact.

4. Best practices for shipping with poly mailers

4.1 Properly sealing and securing poly mailers

Most poly mailers come equipped with a self-sealing adhesive strip. To ensure a secure closure, firmly press along the entire length of the strip after inserting your item. For added security, especially with heavier shipments, consider reinforcing the seams and closure with strong packing tape. Tamper-evident tape can also provide an extra layer of protection, alerting you if the package has been opened during transit.

4.2 Addressing and labeling for efficient delivery

Whether you’re handwriting the address, using pre-printed labels, or printing directly onto the mailer, clarity and accuracy are paramount. Use the correct address format, including the recipient’s full name, street address, city, state, and zip code.

Include a return address in case of delivery issues. When using shipping labels generated online or through shipping software, ensure they are securely attached and that all barcodes are clearly visible for scanning. For international shipments, be sure to include the necessary customs forms, accurately filled out to avoid delays.

5. FAQs about poly mailers

5.1 Are poly mailers waterproof?

Yes, most poly mailers are inherently waterproof due to their polyethylene construction. This makes them an excellent choice for protecting goods from moisture during shipping.

5.2 What sizes do poly mailers come in?

Poly mailers come in a wide variety of sizes, from small 4″ x 6″ mailers suitable for jewelry or small accessories to large 24″ x 24″ mailers for bulky items. Many suppliers offer a comprehensive range of sizes to meet diverse shipping needs.

5.3 Can I print my logo on poly mailers?

Yes, you can customize poly mailers with your logo and other branding elements using various printing methods, including inkjet, screen printing, flexographic, and offset printing. The best method depends on your design complexity, order quantity, and budget.

5.4 Are poly mailers recyclable or eco-friendly?

Some poly mailers are made from recycled materials, and many are technically recyclable. However, whether they are accepted for recycling depends on your local recycling program’s guidelines. Increasingly, eco-friendly options like biodegradable or compostable poly mailers are becoming available.

5.5 What’s the difference between poly mailers and bubble mailers?

Poly mailers are smooth, lightweight plastic envelopes that offer water resistance and durability. Bubble mailers, on the other hand, have a layer of bubble wrap lining the interior, providing added cushioning for fragile items.

6. Packlove – Providing services for poly mailers

Packlove offers a wide selection of high-quality poly mailers in various sizes, thicknesses, and materials, including eco-friendly options. We specialize in custom-printed poly mailers, allowing you to showcase your brand and create a professional image.

In addition to poly mailers, we provide a comprehensive suite of packaging solutions, including our Value Booster Kit, Woven Labels, Heat Transfer Labels, and Rubber Labels to meet all your branding needs. Explore our website or contact us today for a custom quote and let us help you elevate your packaging strategy.

Read more:

Choosing the right method for addressing, labeling, and customizing poly mailers is essential for efficient shipping and effective branding. Whether you opt for the simplicity of handwriting, the professionalism of pre-printed labels, or the efficiency of direct printing, the key is to ensure clarity, accuracy, and durability.

Customizing your poly mailers with your logo and brand colors can significantly enhance your brand image and create a memorable unboxing experience for your customers. By understanding the various options available and implementing best practices for sealing, addressing, and labeling, you can optimize your shipping process and ensure your packages arrive safely and professionally.

Packlove is here to support you with a comprehensive range of poly mailers, customization services, and expert advice to meet all your packaging needs.