What is Satin Fabric? Types, Uses and Care Guide

Satin, with its alluring sheen and luxurious drape, often captivates fashion designers, crafters, and home decorators alike, yet many remain unsure about its true nature and diverse types. Choosing the wrong satin for a project or improperly caring for it can lead to wasted time, money, and ultimately, disappointing results. This lack of understanding can also limit creativity, preventing individuals from fully harnessing the potential of this versatile fabric. This article will unravel the mysteries of satin, providing a comprehensive guide to its properties, types, uses, and care, empowering you to make informed decisions and achieve stunning results in your creative endeavors.

1. What is satin fabric?

1.1 Defining satin: Weave vs. fiber

When we talk about satin, it’s crucial to understand that we’re actually describing a specific type of weave, not the material the fabric is made from. Think of it like this: “satin” is about how the threads are put together, not what the threads themselves are. In fabric making, weaving is the process of interlacing threads – we call them warp and weft – to create the fabric structure.

Satin weave is special because it creates a fabric with a signature look and feel: a smooth, shiny surface on one side and a less lustrous, matte finish on the back. This unique appearance comes directly from the way the threads are woven together in the satin structure.

What’s interesting is that you can achieve this satin weave using many different kinds of fibers. Whether it’s luxurious silk, practical polyester, or durable nylon, the satin weave can be applied to them all. So, to reiterate, the term “satin” truly refers to the weaving technique used.

1.2 The satin weave: Understanding the structure

The secret behind satin’s distinctive look and feel lies in its weave structure, specifically what we call “floats.” Imagine the fabric being built from two sets of threads: warp yarns that run lengthwise along the fabric, and weft yarns that run crosswise.

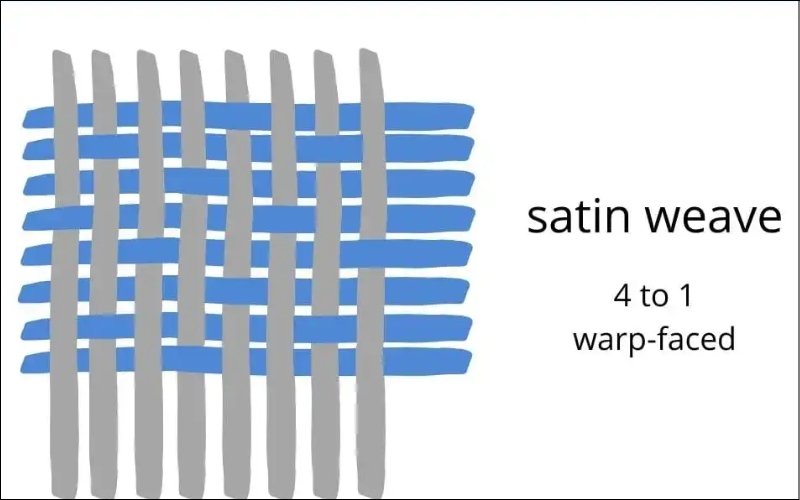

In a typical satin weave, the warp yarns take center stage on the surface. They “float” over several weft yarns before being interlaced or stitched down underneath. This means that instead of a tight crisscross pattern you might see in other weaves, satin has longer segments of warp yarns lying on top.

This floating effect is key to satin’s signature characteristics. Think about it: when light hits a surface, it reflects back. Because the warp yarns in a satin weave float over multiple weft yarns, there are fewer points where the threads are actually interlaced and broken up.

This creates a smoother, more continuous surface for light to bounce off of. This even reflection of light is what gives satin its beautiful, lustrous sheen. On the reverse side of the fabric, you’ll see a duller appearance because you’re seeing the underside of these floats and more of the interlacing points.

While warp-faced satins are more common, it’s worth knowing that there are also weft-faced satins. In these variations, it’s the weft yarns that do the floating over the warp yarns, bringing the weft threads to the forefront of the fabric’s surface. The principle is the same – creating those smooth, light-reflective “floats” – just with a different set of yarns taking the lead.

For example, a common satin weave might have a warp yarn floating over four weft yarns. This “4-harness satin” means the warp thread goes over four weft threads, then under one, and then the pattern repeats. These “floats” are what minimize the points of interlacing, resulting in that incredibly smooth surface that defines satin and makes it so appealing for various clothing applications.

1.3 Satin vs. other fundamental weaves

To understand what makes satin unique, it’s helpful to compare it to other fundamental weaves like plain weave and twill weave. Plain weave, the simplest, is a one-over, one-under pattern, creating a balanced, less lustrous fabric. Twill weave, recognized by its diagonal pattern, has floats, but they are shorter and more staggered than in satin, resulting in a more textured surface. Satin, with its long floats, stands out for its smooth, glossy surface and luxurious feel.

2. What is satin fabric made from? Materials and their impact

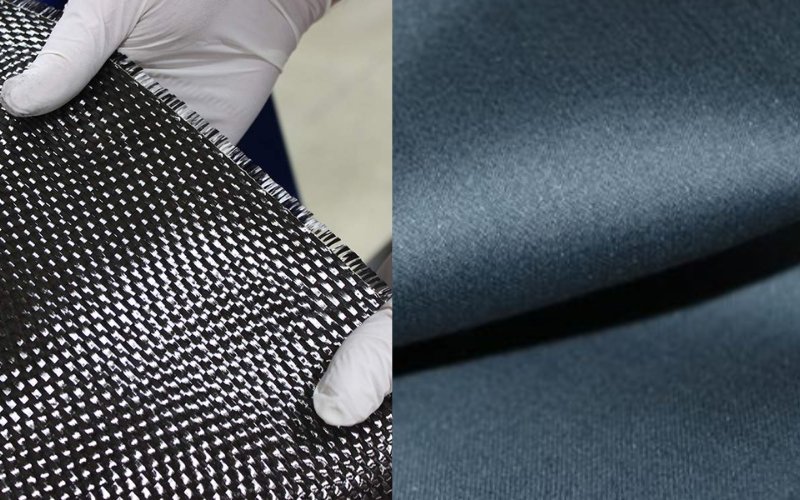

2.1 From silk to synthetics: A history of Satin Fibers

Historically, satin was exclusively made from silk, a luxurious natural fiber. The smooth, continuous nature of silk fibers contributed to the fabric’s high sheen and elegant drape. However, modern satin can be made from a variety of fibers, including silk, polyester, nylon, rayon, and acetate. Each fiber brings its own set of properties to the fabric, affecting its appearance, feel, durability, and cost.

2.2 Understanding filament vs. staple fibers in satin

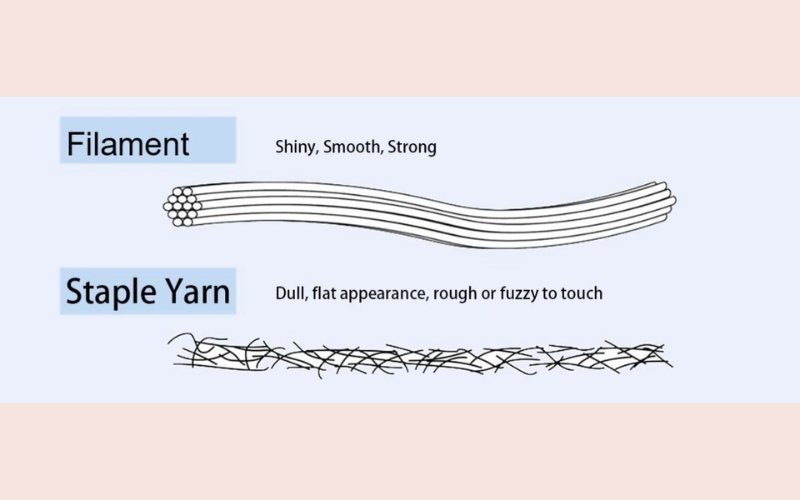

Fibers are classified as either filament or staple. Filament fibers are long and continuous, like silk or synthetic fibers such as polyester. Staple fibers are short, like cotton. When a satin weave is made with filament fibers, the resulting fabric is typically called “satin.” However, when a satin weave is made with staple fibers, like cotton, it’s referred to as “sateen.” This distinction is important because fiber length affects the fabric’s properties.

2.3. How fiber choice affects satin’s properties

The choice of fiber significantly impacts the characteristics of satin. Silk satin is renowned for its luxurious feel, softness, breathability, and natural sheen. It’s also the most expensive and delicate. Polyester satin, often called polysatin, is a more affordable and durable alternative. It’s wrinkle-resistant but less breathable than silk. Other synthetic fibers like nylon, rayon, and acetate offer varying properties, often used to create specific types of satin with unique characteristics.

3. How is satin fabric made? The weaving process

3.1 The satin weave technique: Creating the characteristic surface

Satin fabric is created on a loom, a machine that interlaces warp and weft yarns to form fabric. The satin weave technique involves floating warp yarns over multiple weft yarns, creating the signature smooth surface. This interlacing pattern differs significantly from plain or twill weaves, where the yarns interlace more frequently. The specific pattern of floats and interlacings determines the fabric’s appearance and properties.

3.2 Variations in satin weave: Harnesses and their effects

In weaving, harnesses are frames that lift and lower warp yarns to create the desired pattern. Satin weaves are often described by the number of harnesses used, such as 4-harness, 5-harness, or 8-harness. The number of harnesses affects the length of the floats. For example, in a 4-harness satin, the warp yarn floats over three weft yarns and under one. In an 8-harness satin, the warp floats over seven weft yarns. Longer floats, achieved with more harnesses, result in a smoother, more lustrous surface but can also make the fabric more prone to snagging.

4. Exploring the diverse world of satin fabric types

4.1 Common types of satin and their characteristics

The beauty of satin lies not just in its weave, but also in the incredible variety it offers. Depending on the fibers used and the specific weaving techniques, satin can take on many different forms, each suited to different purposes. For clothing businesses, understanding these nuances is key to selecting the perfect satin for your designs. Let’s explore some common types:

- Antique Satin: Imagine a satin with a touch of vintage charm. Antique satin stands out with its subtly textured surface. Unlike typical smooth satins, it has a slightly raised, almost grainy feel. Interestingly, it’s also reversible, meaning both sides can be used as the face of the fabric, offering design flexibility. While often found in home décor like upholstery due to its durability and unique texture, antique satin can also lend a sophisticated, understated elegance to garments, particularly structured pieces like jackets or skirts where a less overtly shiny look is desired.

- Baronet Satin: If you’re looking for high-impact shine, Baronet satin is your go-to. This type is known for its exceptionally lustrous surface – it really catches the light! Typically constructed with a silk or rayon warp (the lengthwise threads that create the surface) and a cotton weft (the crosswise threads for structure), Baronet satin achieves a dramatic sheen while maintaining a degree of stability from the cotton backing. Think glamorous evening wear, statement linings, or decorative accents where a rich, eye-catching sheen is paramount.

- Charmeuse Satin: Synonymous with luxury and fluidity, Charmeuse satin is prized for its incredibly soft drape and lightweight feel. It has the classic satin combination of a glossy front and a matte back. Often woven from silk or synthetic fibers like polyester, Charmeuse drapes beautifully against the body, making it ideal for lingerie, flowing dresses, blouses, and scarves. Its delicate nature and elegant sheen make it a popular choice for garments that whisper sophistication and comfort.

- Crepe-back Satin: This satin offers versatility in texture. As the name suggests, Crepe-back satin is reversible, featuring a smooth, satin face on one side and a subtly textured crepe finish on the reverse. This dual nature allows designers to play with contrasting textures within a single garment. Use the satin side for a classic sheen, or flip to the crepe side for a more muted, matte effect. This type is excellent for garments where you want to incorporate textural interest, such as dresses, jackets, or even decorative trims.

- Duchess Satin: For structured elegance and formal grandeur, Duchess satin is the queen. This is a heavy, luxurious satin known for its substantial weight and stiffness. It holds its shape exceptionally well, making it perfect for structured garments like bridal gowns, corsets, tailored jackets, and formal evening wear. Duchess satin exudes opulence and sophistication, providing a crisp, sculpted silhouette.

- Messaline Satin: Imagine a lighter, more fluid version of classic satin. Messaline satin is a lightweight and incredibly soft fabric, typically woven from silk or rayon. It retains the signature high shine of satin but in a more delicate and flowing form. Its fine weave and beautiful drape make it perfect for delicate garments like lingerie, linings, soft blouses, and flowing evening gowns where a luxurious feel and elegant movement are desired without excessive weight or stiffness.

- Polysatin: Practicality meets sheen with Polysatin. Made entirely from polyester fibers, this type of satin offers the visual appeal of satin with enhanced durability and easy care. Polysatin is known for its wrinkle resistance, a huge advantage for garments that need to travel or be worn for extended periods. It’s also typically more affordable than silk satins, making it a cost-effective option for various apparel applications, from linings and costumes to more accessible fashion pieces.

- Slipper Satin: Don’t let the name fool you – Slipper satin is more robust than it sounds! This is a stiff, medium to heavyweight satin, known for its durability and ability to hold its shape. While traditionally used for slippers and shoes due to its sturdiness, Slipper satin is also excellent for accessories like handbags, belts, and even structured garment details where you need a satin with more body and less drape.

4.2 Choosing the right satin type for your project

Selecting the appropriate satin type depends on the specific needs of your project. Consider factors like the desired drape, weight, sheen, durability, and budget. For example, Charmeuse is an excellent choice for flowing garments due to its lightweight and drapability. Duchess satin, with its stiffness and structure, is well-suited for formal gowns. Polysatin, being affordable and wrinkle-resistant, is often used for costumes or projects where easy care is essential.

5. Characteristics of satin fabric: Understanding its unique properties

5.1 The signature sheen and smoothness of satin

Satin is renowned for its signature sheen and smoothness. These qualities are a direct result of the satin weave structure. The long floats on the fabric’s surface reflect light evenly, creating a lustrous appearance. The minimal interlacing points also contribute to the smooth, luxurious feel of the fabric.

5.2 Drape and softness: The luxurious feel of satin

Satin is known for its beautiful drape, meaning the way it hangs and flows. The drape is influenced by both the fiber and the weave. Silk satin, for instance, tends to have a more fluid drape than polyester satin. The long floats in the satin weave also contribute to the fabric’s softness and luxurious feel against the skin.

5.3 Durability, snagging, and sewing considerations

The durability of satin varies depending on the fiber used. Silk satin is more delicate than polyester satin. However, all types of satin are prone to snagging due to the long floats on the surface. When sewing with satin, it’s important to use sharp, fine needles and appropriate thread to avoid damaging the fabric. Careful handling is essential to prevent snags and maintain the fabric’s smooth appearance.

6. Uses of satin fabric: From fashion to home décor

6.1 Satin in fashion: Evening wear, lingerie, and more

Satin has long been a favorite fabric in the fashion world, particularly for evening wear. Its luxurious sheen and drape make it ideal for gowns, bridal wear, and other formal attire. Satin is also a popular choice for lingerie and sleepwear due to its soft, smooth feel against the skin. In recent years, satin has made its way into everyday wear, with satin shirts and blouses becoming increasingly popular.

6.2 Satin in home décor: Upholstery, bedding, and beyond

Satin has a rich history in home décor, particularly in upholstery. Antique satin, with its textured surface, was often used for furniture. Today, satin is still used in upholstery, as well as for bedding, such as sheets and pillowcases. The smooth, cool feel of satin makes it a comfortable choice for bedding. Satin is also used for other home décor applications, such as curtains and decorative pillows, adding a touch of elegance to any room.

6.3 Satin in accessories, footwear, and crafts

Satin is a popular choice for accessories, particularly evening bags and clutches. Its sheen and luxurious feel add a touch of sophistication to any outfit. Satin is also used in footwear, from delicate ballet shoes to elegant high heels. In the crafting world, satin ribbons are a staple for adding a decorative touch to gifts, clothing, and other projects.

7. A journey through time: The history of satin fabric

7.1 From ancient China to the silk road: The origins of satin

Satin’s origins can be traced back to ancient China, where it was originally made exclusively from silk. The Chinese mastered the art of silk production and weaving, creating luxurious fabrics that were highly prized. The Silk Road, a network of trade routes connecting the East and West, played a significant role in the spread of satin to other parts of the world.

7.2 Satin in Europe: A fabric of royalty and luxury

Satin weaving techniques reached Europe from the Arab world during the Middle Ages, and Italy became the first European country to produce satin in the twelfth century, quickly becoming a symbol of wealth and luxury. Initially, it was a fabric reserved for the elite, used for royal garments and opulent furnishings.

The port city of Quanzhou in China, known as “Zayton” in Arabic, was a major center for satin production and its trade to Europe during this period.

7.3 The evolution of satin: From silk to synthetics

The Industrial Revolution brought significant changes to satin manufacturing. The invention of new machinery and the development of synthetic fibers, like polyester and nylon, made satin more accessible to the masses. These advancements allowed for mass production and a wider range of satin types at different price points.

8. Satin vs. other fabrics: Understanding the differences

8.1 Satin vs. sateen: Fiber and sustainability

When discussing fabrics with a sheen, “satin” and “sateen” often come up, and while they share a similar smooth surface, they are fundamentally different. Understanding these differences is crucial for making informed fabric choices for your clothing line. The key distinctions lie in the type of fiber used and, consequently, the fabric’s properties and sustainability.

The primary difference is in the fiber:

- Satin: Traditionally, satin is woven using filament fibers. Filament fibers are long, continuous strands. Think of silk, which is a natural filament fiber, or polyester and nylon, which are synthetic filament fibers. Because of these long, continuous fibers, satin tends to have a very smooth, luxurious drape and a high level of sheen.

- Sateen: In contrast, sateen is woven using staple fibers. Staple fibers are shorter length fibers. Cotton is the most common staple fiber used for sateen. Other staple fibers include linen and wool (though less common in sateen). The use of staple fibers gives sateen a softer, more subtle sheen compared to satin.

Let’s break down the key differences further:

- Sheen: Satin is known for its high, almost glossy sheen, thanks to the long, smooth filament fibers that reflect light intensely. Sateen, made from shorter staple fibers like cotton, has a softer, more muted luster. The sheen is still present, giving it a refined look, but it’s less overtly shiny than satin. Think of it as a gentle glow rather than a high shine.

- Durability: Generally, sateen tends to be more durable than many types of satin, especially those made from delicate silk. Cotton sateen, in particular, is known for its good abrasion resistance and strength, making it suitable for items that will see more regular wear and washing. While polyester satins can be quite durable, silk satins are more delicate and require more careful handling.

- Drape: Satin, especially silk satin and charmeuse satin, is prized for its exceptional drape – the way it falls and hangs. It’s fluid and moves beautifully. Sateen, while still having a nice drape, is often a bit more structured and less fluid than a very fine satin. The drape of sateen will also depend on the weight and weave density.

- Sustainability: This is a significant point of difference, especially in today’s market. Cotton sateen is generally considered a more sustainable option compared to many synthetic satins like polyester satin. Cotton is a natural fiber, and while its production does have environmental impacts (water usage, pesticides in conventional cotton), it is biodegradable and renewable. Polyester satin, on the other hand, is derived from petroleum, a fossil fuel, and is not biodegradable. Silk satin, while a natural fiber, also has its own sustainability considerations related to silk production. Therefore, if sustainability is a priority for your brand, cotton sateen can be a more environmentally conscious choice than synthetic satins.

In summary:

- Choose satin when you desire a high-shine, luxurious look and a fluid drape, keeping in mind the fiber content for durability and care. Ideal for evening wear, lingerie, linings, and special occasion garments.

- Choose sateen when you want a softer sheen, good durability, and potentially a more sustainable option (especially cotton sateen). Well-suited for more everyday garments, blouses, skirts, home textiles, and items where a balance of elegance and practicality is needed.

By understanding these key differences, you can confidently select the right fabric – satin or sateen – to best meet the needs of your clothing designs and brand values.

8.2 Satin vs. silk: Weave vs. fiber, luxury vs. price

Silk is a natural fiber, while satin is a weave. Satin can be made from silk, but it can also be made from other fibers like polyester. Silk satin is considered the most luxurious and expensive type of satin due to its natural sheen, softness, and breathability. Satin made from synthetic fibers offers a more affordable alternative, though it may lack some of the desirable properties of silk.

8.3 Satin vs. cotton: Smoothness, breathability, and cost

Satin and cotton differ significantly in their properties. Satin is known for its smoothness and sheen, while cotton is typically more matte and textured. Cotton is generally more breathable than synthetic satin but less breathable than silk satin. Cotton is also more wrinkle-prone than many types of satin. In terms of cost, cotton is usually more affordable than silk satin but can be comparable in price to polyester satin.

9. Caring for your satin garments and items

9.1 Washing and drying satin: Best practices

Proper care is essential to maintain the beauty and longevity of satin. When washing satin, it’s crucial to check the care label first, as the recommended method can vary depending on the fiber content. Generally, hand washing with cold water and a mild detergent is the safest method.

Some satins, particularly synthetics, may tolerate a gentle machine wash cycle with cold water, but this should be avoided for delicate silk satins. Use a mild detergent formulated for delicate fabrics. Avoid harsh chemicals or bleach, which can damage the fibers.

For drying, air drying is the gentlest option. Hang the item or lay it flat on a clean towel, away from direct sunlight or heat. Some satins can be tumble-dried on a low-heat setting, but always check the care label first.

9.2 Ironing and steaming satin: Maintaining the sheen

Ironing satin requires caution to avoid damaging the delicate fibers or creating unwanted marks. Use a low-heat setting on your iron and always use a pressing cloth, a thin piece of fabric placed between the iron and the satin, to protect the fabric. Steaming is a gentler alternative to ironing and can be an effective way to remove wrinkles without direct heat contact.

9.3 Storing satin: Preventing damage and snags

Proper storage is crucial for preventing damage to satin items. To avoid snags, store satin garments on padded hangers or fold them carefully and place them in a drawer or storage box. Avoid storing satin with items that have rough surfaces or sharp embellishments. For long-term storage, wrap satin items in acid-free tissue paper to protect them from dust and discoloration.

10. FAQs about what is satin fabric

10.1 Is satin a natural fabric?

Satin can be either natural or synthetic, depending on the fibers used to make it. Silk satin is a natural fabric, while polyester satin is synthetic.

10.2 What is the difference between satin and taffeta?

Satin and taffeta are both elegant fabrics often used in formal wear, but they differ significantly in their weave, appearance, and feel. Satin has a characteristic glossy surface and a dull back due to its unique weave structure where warp or weft yarns float over multiple yarns of the opposite direction, creating a smooth, lustrous face.

Taffeta, on the other hand, is a crisp, plain-woven fabric made with a simple over-and-under weave, resulting in a smooth, slightly shiny surface on both sides. Taffeta also has a distinctive rustling sound, often described as a “whisper,” due to its stiff, tightly woven structure. While satin drapes beautifully and feels soft, taffeta holds its shape well and has a more structured drape.

10.3 Is satin good for bedding?

Yes, satin can be an excellent choice for bedding due to its smooth, luxurious feel against the skin. Silk satin is particularly breathable and helps regulate temperature. Polyester satin, while less breathable, is more affordable and wrinkle-resistant.

10.4 How can you tell if satin is high quality?

High-quality satin will have a rich, even sheen, a smooth surface without snags, and a substantial weight. It should drape beautifully and feel luxurious to the touch. The fiber content also plays a role in quality, with silk satin generally considered higher quality than synthetic alternatives.

10.5 What does GSM mean for satin fabric?

GSM stands for “grams per square meter” and is a measure of fabric weight and density. A higher GSM generally indicates a thicker, more durable satin. For example, a lightweight charmeuse might have a GSM of 50-80, while a heavier duchess satin could have a GSM of 150 or more.

11. Packlove – Providing custom service for satin fabric products

11.1 Packlove – Custom printing and design

Packlove is a company that specializes in custom printing and design services. We help individuals and businesses create personalized products, including those made with satin fabric or related materials. Our expertise lies in turning your creative vision into reality, offering a wide range of customization options to meet your specific needs.

11.2 Packlove’s Products

- Woven Labels: Packlove offers custom woven labels that can be made with a satin weave, adding a touch of luxury and professionalism to garments and products. These labels can be customized in terms of size, color, and design, allowing you to perfectly represent your brand.

- Heat Transfer Labels: Our heat transfer labels provide a durable and vibrant branding solution that can be applied to satin garments. These labels are versatile and can be used on a variety of fabrics, including those with a satin weave.

- Zipper Bags: We offer custom-printed zipper bags that are ideal for packaging satin items like lingerie or accessories. These bags not only protect your products but also enhance your brand’s presentation.

- Value Booster Kit: The Value Booster Kit is designed to help businesses elevate their brand image, engage customers, and boost sales through a comprehensive set of customizable branding materials.

- Poly Mailers: Our customizable poly mailers are also suitable for shipping satin items, ensuring they arrive safely and in style.

We invite you to visit the Packlove website to explore our wide range of product options and design possibilities. Our team is ready to assist you in creating custom satin fabric products that meet your unique requirements. Contact us today for personalized quotes and let us help you bring your creative vision to life.

Read more:

Satin fabric, with its signature sheen and luxurious feel, has a rich history and a wide range of applications. From its origins in ancient China to its modern-day use in fashion, home décor, and beyond, satin continues to be a beloved fabric for its versatility and elegance. Understanding the different types of satin, their properties, and proper care techniques is essential for making informed decisions when choosing and using this beautiful fabric. Packlove is your trusted partner for custom satin fabric product needs, offering a range of services to help you create unique and personalized items that reflect your style and brand.