How to Tell if a Patch is Iron-On: Foolproof Methods

Personalized clothing and accessories using patches are increasingly popular, allowing for unique self-expression and customization. However, applying patches correctly requires knowing whether they are iron-on or meant for sewing. Misidentifying an iron-on patch can lead to improper application and potentially damage your items. This guide provides simple yet effective methods for identifying iron-on patches, empowering you to personalize your belongings with confidence and avoid costly mistakes. Learn these identification techniques and confidently embark on your patch personalization projects.

1. Identifying iron-on patches: Simple and effective methods

1.1 The visual inspection: What to look for

A simple visual inspection often reveals whether a patch is designed for ironing or sewing. Iron-on patches typically have a distinct backing that distinguishes them. This backing is usually shiny, smooth, and often appears translucent or semi-transparent. This smooth, sometimes slightly glossy surface is the heat-activated adhesive that bonds the patch to the fabric when heated.

In contrast, sew-on patches have a backing that is noticeably different. Their backing is typically matte and has a fabric-like texture, often resembling the material of the patch itself. This matte backing provides a surface for stitching the patch onto the garment. Comparing these visual cues—shiny and smooth versus matte and fabric-like—is a quick and effective way to differentiate between iron-on and sew-on patches.

1.2 The touch test: Feeling the difference

Beyond visual cues, a simple touch test can help confirm whether a patch is iron-on. Gently feel the back of the patch with your fingertips. An iron-on patch backing will typically feel smooth, slightly glossy, or even somewhat plastic-like to the touch. This smooth texture distinguishes it from the more textured, fabric-like feel of a sew-on patch.

The difference in tactile sensation is often quite noticeable. Sew-on patches will generally have a more fibrous or woven texture, whereas the iron-on backing will feel distinctly smoother and almost slick due to the heat-activated adhesive. This touch test, combined with a visual inspection, provides a reliable way to differentiate between iron-on and sew-on patches.

1.3 The water droplet test: A quick and easy check

A simple water droplet test can sometimes distinguish between iron-on and sew-on patches. Carefully place a single drop of water on the patch’s backing, ideally in an inconspicuous area, and observe its behavior. If the droplet beads up and remains on the surface, this suggests the presence of a heat-activated adhesive, indicating an iron-on patch.

Conversely, if the water droplet is absorbed into the patch’s backing, this implies the absence of adhesive, pointing towards a sew-on or other non-iron-on patch type. This straightforward test provides valuable insight into the patch’s construction and guides your application approach. Knowing whether your patch is iron-on allows you to proceed with the correct application method, ensuring a successful and damage-free result.

1.4 The heat response test (use with caution): A more definitive approach

A heat response test, conducted cautiously, can definitively identify an iron-on patch. Using a low-heat source like a hair dryer or an iron on its lowest setting, position the patch on a heat-resistant surface with the backing facing up. Hold the heat source several inches away from the patch, avoiding direct contact or excessive heat.

Gradually apply warmth to the backing for a few seconds, observing closely for any changes. If the patch is iron-on, the adhesive will begin to soften visibly. Avoid overheating, as this can damage the patch or weaken the adhesive. While this test provides a conclusive result, exercise care when applying heat to prevent damage.

1.5 Checking the edge: Thickness as a clue

Examining a patch’s edge thickness can offer clues about its type. Iron-on patches generally have thinner edges compared to sew-on patches. Using a ruler or calipers, measure the patch’s edge width. A sleek, uniform edge often suggests an iron-on patch, relying on adhesive rather than stitching for attachment.

Sew-on patches typically have thicker edges to accommodate the stitched border. Comparing the patch’s edge to known examples of iron-on and sew-on patches can help identify its type. While not a definitive test on its own, edge thickness, combined with other assessment methods, provides valuable information for determining the patch’s construction and appropriate application method.

1.6 When in doubt, contact the manufacturer: The surest way

When uncertain about a patch’s type, contacting the manufacturer directly provides the most reliable information. This is especially important if the patch lacks accompanying instructions or if the identification tests yield inconclusive results. Inquire about the recommended application method, the backing material’s composition, and whether heat is required for adhesion.

The manufacturer can definitively confirm whether the patch is iron-on, sew-on, or another type, ensuring you use the correct application technique and avoid potential damage to your garment. Verifying this information directly with the source eliminates guesswork and guarantees successful patch application.

2. Understanding different patch types and their applications

2.1 Embroidered Patches

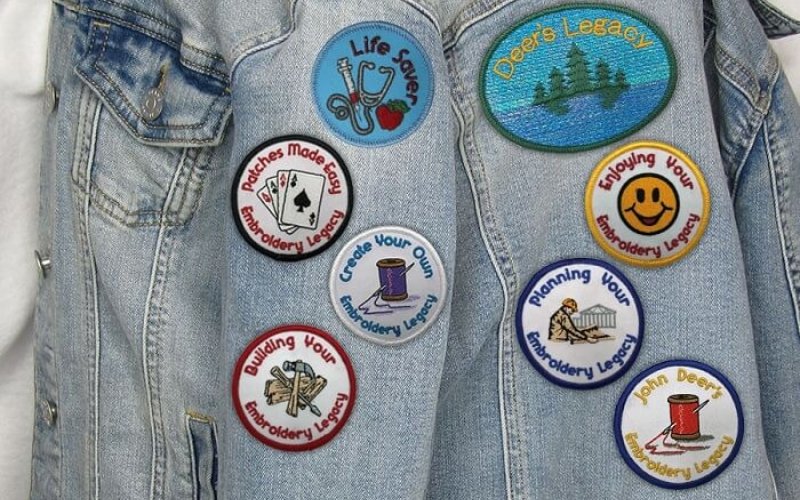

Embroidered patches, known for their textured appearance and durability, are a popular choice for customizing various fabrics. Created by stitching intricate designs onto a backing material, these patches offer a tactile and visually appealing embellishment. The raised threads create a textured surface that adds depth and dimension to the design. Embroidered patches are typically quite durable, able to withstand repeated washing and wear.

Depending on the backing material, embroidered patches can be either iron-on or sew-on. Iron-on embroidered patches have a heat-activated adhesive backing, while sew-on versions require stitching for attachment. This versatility makes them suitable for a wide range of applications, from personalizing clothing and accessories to representing affiliations and achievements. The intricate designs achievable with embroidery make these patches a versatile and enduring choice for customization.

2.2 Woven patches

Woven patches, crafted with a tight weave, excel at reproducing intricate designs with remarkable detail. Their construction results in a lightweight and flexible patch, making them comfortable to wear and suitable for various fabrics. The tight weave allows for fine lines and complex patterns, making woven patches ideal for intricate logos, detailed artwork, or text-heavy designs.

Similar to embroidered patches, woven patches can be either iron-on or sew-on, depending on the backing material used. Iron-on woven patches feature a heat-activated adhesive, while sew-on versions are designed for stitching. This versatility makes them a popular choice for customizing apparel, bags, and other fabric items where detail and flexibility are desired.

2.3 Printed patches

Printed patches frequently employ heat-transfer technology to create vibrant, detailed designs on a smooth surface. This process allows for a wide range of colors and intricate details, making printed patches ideal for reproducing complex artwork, photographs, or gradients. The design is printed onto a special transfer paper, then applied to the patch material using heat and pressure.

Due to this heat-transfer process, printed patches are generally iron-on, utilizing a heat-activated adhesive backing for application. The resulting patch has a smooth, almost glossy surface, distinct from the textured feel of embroidered or woven patches. Printed patches offer a versatile and visually striking option for customizing various items, particularly when vibrant colors and intricate details are desired.

3. FAQs about patches

3.1 Can any patch be ironed on?

No, only patches with a heat-activated adhesive backing can be ironed on. Always check the backing or contact the manufacturer if unsure.

3.2 What if my patch doesn’t have instructions?

Use the methods described in this article to determine if it’s iron-on. If still unsure, contact the manufacturer.

3.3 Can I sew on an iron-on patch?

Yes, for added security, you can stitch around the edges of an iron-on patch after ironing it on.

3.4 What if my iron-on patch isn’t sticking?

Ensure you’re using enough heat and pressure. A heat press or a damp cloth can help. Try ironing on a hard, flat surface.

3.5 How do I remove an iron-on patch?

Carefully apply heat and gently peel the patch off. An adhesive remover may be helpful.

4. My Pack Love – Providing services for custom patches and packaging

My Pack Love is your one-stop shop for high-quality custom patches and a wide range of branding and packaging solutions. We specialize in creating custom embroidered patches, woven patches, and printed patches, offering a variety of options to suit your specific needs and design preferences. Beyond patches, My Pack Love also provides custom stickers, labels, and various packaging solutions to enhance your brand identity and create a cohesive brand experience.

With expertise in design and production, we offer fast turnaround times and competitive pricing, ensuring you receive exceptional products and service. Whether you’re looking to personalize apparel, create promotional items, or enhance your packaging, My Pack Love has the expertise and resources to bring your vision to life. Visit mypacklove.com today to explore our wide selection and create your perfect custom patches, stickers, labels, and packaging solutions!

Read More:

- Are Poly Mailers Biodegradable? Eco-Friendly Alternatives & FAQs

- Ship Poly Mailers with Stamps: USPS Rules, Costs and Tips

- Are poly mailers recyclable? A complete guide

Identifying iron-on patches is crucial for successful application and preventing damage to your items. Remember the key methods: visually inspecting the backing for a shiny, smooth, and often translucent appearance; performing a touch test to feel for a smooth, plastic-like texture; and conducting a water droplet test to observe whether the water beads or absorbs. Proper identification ensures you use the correct application method, avoiding potential mishaps and achieving a professional-looking result. For all your custom patch needs, including embroidered, woven, and printed options, explore the wide selection and expert services at mypacklove.com. Don’t risk ruining your belongings—take the time to identify your patches correctly and personalize with confidence. Visit us today to start creating!