You May Also Like

Elevate your brand with durable, precision-crafted woven labels available in various styles and colors, featuring sew-on or heat press application.

Starts $0.1/each

Choose durable, cost-effective heat transfer labels for both light and dark garments. They maintain their appearance after multiple washes.

Starts $0.16/each

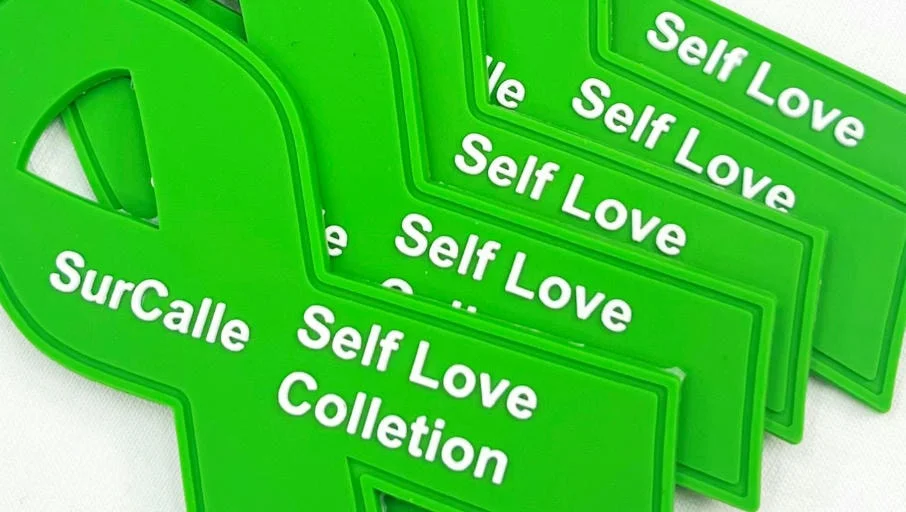

Opt for waterproof, durable, and flexible rubber labels that meet diverse decoration needs with options for sew-on, heat press, or velcro backing, making your products stand out.

Starts $0.67/each

Showcase your brand with custom zipper bags. These eco-friendly bags come in various sizes to preserve and promote your products.

Starts $0.49/each

FAQs

Don't hesitate to ask. Contact us

What finishes are available?

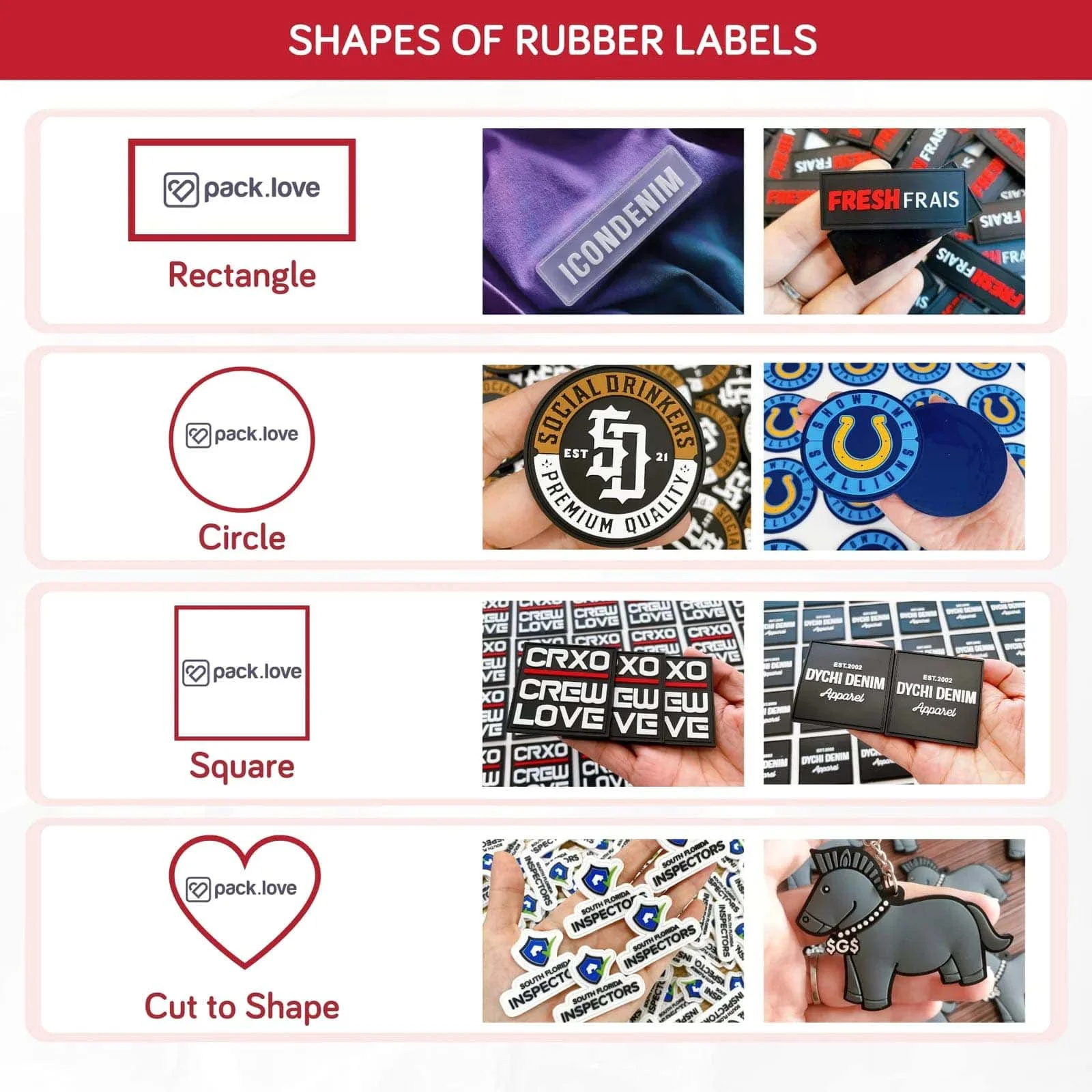

We offer sew-on, iron-on, and velcro options. Shapes are fully customizable, and there’s no limit on size or shape — we’ll produce your label exactly the way you envision it. All rubber/PVC labels are custom-made based on your design, preferred shape, and exact dimensions.

What’s the MOQ?

Minimum order starts at 50 pieces/design

How long is production time?

Production takes approximately 8–11 business days after you confirm your mockup. Rubber labels typically take longer than other items because each design requires a custom mold to be created before production begins.

Any design tips I should know?

Definitely. For rubber labels, avoid small gaps and elements thinner than 0.8mm, as they may not mold cleanly. Designs with 1–6 solid colors work best. Keep some spacing between color areas to prevent colors from bleeding during casting. Rounded corners and bolder lines create the clearest results.

How do I apply heat press rubber labels?

To ensure your patch looks professionally pressed every time, follow these steps:

1. Position Your Patch: Place the rubber label on your garment and secure it with thermal (heat-resistant) tape so it stays in position during pressing.

2. Load Garment Face Down: Flip the garment over so the patch is facing downward and in direct contact with the lower plate of your heat press. This helps melt the low-melt adhesive on the back of the patch without affecting the visible surface.

3. Press: Cover the garment with a protective sheet and press at 335°F (168°C) for 25 seconds using hard pressure (50–60 PSI). Let it cool for at least 30 seconds before removing the thermal tape. This ensures proper adhesion.

4. For Thick Fabrics: If pressing doesn’t fully adhere the patch on thicker items (like hoodies or jackets), try turning the garment inside out and press from the back using the same temperature and pressure settings.

5. For Hats: For PVC rubber patches on hats, both top and bottom heat are required. Using only top heat can damage the patch. Always use a press designed to apply heat from both directions for best results.

Overall total

$ 145,00

Final charge may differ due to proration, credit refunds, or local taxes.

Pancho R Soto

•I received them already thank you really like them💯

Christopher Pearson

•Package arrived today. Everything was there. 🤝Thank you. And I will get back to you very soon for tags and stickers 💯

Everything NYC

•Hey thanks for the order I’m happy with the order