Knit vs Woven Fabric: What’s the Difference? (Ultimate Guide)

Are you a sewing beginner feeling lost in the world of fabric? Do you find yourself staring at patterns, unsure whether to choose a knit or a woven? Or perhaps you’re a more experienced sewer looking to deepen your understanding of textile construction.

Even for consumers, understanding the difference between knit and woven fabrics can help you decipher clothing labels and make more informed purchasing decisions. Choosing the wrong fabric type for a sewing project is a common mistake, and a frustrating one. It can lead to ill-fitting garments, construction headaches, and projects that simply don’t look or function as intended.

This comprehensive guide demystifies the fundamental differences between knit and woven fabrics. You’ll learn how each type of fabric is made, explore their unique properties (stretch, drape, durability, etc.), discover their typical uses, and gain practical skills for identifying them.

We’ll also cover essential sewing techniques specific to each fabric type. Armed with this knowledge, you’ll be able to confidently select the right fabric for every project, improve your sewing skills, and create garments that fit beautifully and last longer.

1. Unraveling the Mystery of Knit vs. Woven

Understanding the difference between knit and woven fabrics is one of the most fundamental concepts in sewing and textiles. It’s the bedrock upon which all other fabric knowledge is built. This guide provides a comprehensive comparison of these two primary fabric types, explaining their construction, properties, uses, and sewing considerations. Let’s demystify these terms and empower you to make informed fabric choices.

2. The Foundation: How Knit and Woven Fabrics are Made

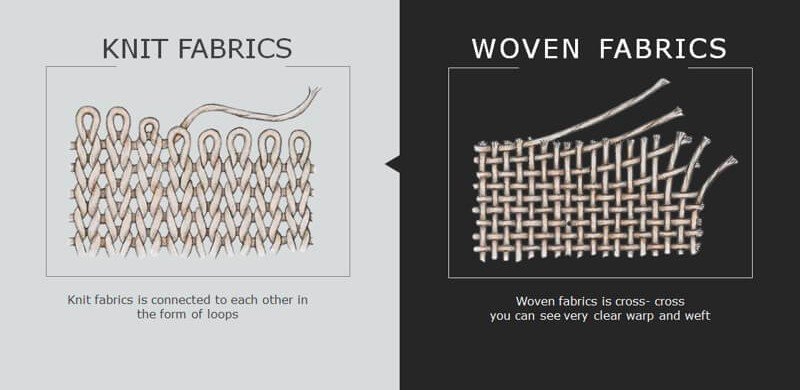

The core difference between knit and woven fabrics lies in their construction – how the yarns or threads are assembled to create the fabric.

2.1 Knit Fabric: The Art of Interlooping

Knit fabric is created from a single yarn (or a set of yarns) that is continuously looped to create a structure that looks like tiny braids or interlocked chains. Imagine taking a single, long piece of yarn and creating a series of interconnected loops – that’s the essence of knitting.

There are two main categories of knit fabric construction:

- Weft Knitting: In weft knitting, the loops run horizontally, across the width of the fabric. This is the most common type of knitting for apparel fabrics. Think of hand-knitting with needles – that’s a form of weft knitting.

- Warp Knitting: In warp knitting, the loops run vertically, along the length of the fabric. Warp knits are generally more stable and less stretchy than weft knits. They are often used for linings, tricot, and some specialized applications.

Knit fabrics are often produced on two main types of machines:

- Circular Knitting Machines: These machines knit the fabric in a continuous cylinder or tube. This results in a “light” weight fabric that is often seamless along the sides. Circular knit fabrics are commonly used for t-shirts, leggings, and other garments where a seamless tube is advantageous. Gauges commonly range from 12 to 22.

- Flat Knitting Machines: These machines knit the fabric in flat sheets. Flat knitting is often used to create thicker, more structured knit fabrics, like those used for sweaters. Flat knitting also allows for shaping the fabric during the knitting process (e.g., creating the curves of a sweater sleeve). Gauges typically range from 2 to 10.

The looped structure of knit fabric is what gives it its characteristic stretch and flexibility.

2.2 Woven Fabric: The Interlacing of Warp and Weft

Woven fabric, in contrast to knit fabric, is made from multiple yarns that interlace at right angles to each other. This interlacing creates a stable, grid-like structure, often described as looking like a tiny checkerboard.

To understand woven fabric construction, you need to know two key terms:

- Warp Yarns: These are the yarns that run vertically, along the length of the fabric, on the loom. They are held taut under tension.

- Weft Yarns: These are the yarns that run horizontally, across the width of the fabric, on the loom. They interlace over and under the warp yarns.

The process of weaving involves interlacing these warp and weft yarns in a specific pattern, creating a stable and (generally) non-stretchy fabric.

There are three basic types of weave structures:

- Plain Weave: The simplest and most common weave. The weft yarn goes over one warp yarn, then under the next, alternating in a simple, perpendicular pattern. This creates a strong and stable fabric. Examples include muslin, broadcloth, and poplin.

- Twill Weave: Characterized by a diagonal rib pattern on the fabric surface. This is created by the weft yarn floating over multiple warp yarns, then under one, in a staggered pattern. Twill weaves are known for their durability. Examples include denim, chino, and gabardine.

- Satin Weave: Creates a smooth, lustrous fabric with excellent drape. In a satin weave, either the warp yarns float over multiple weft yarns (warp-faced satin), or the weft yarns float over multiple warp yarns (weft-faced sateen). This creates long “floats” of yarn on the surface, which reflect light and give the fabric its characteristic sheen.

The interlaced structure of woven fabric is what gives it its stability and (generally) lack of stretch.

3. Identifying Knit vs. Woven: The Three Key Tests

Knowing the theoretical differences is helpful, but being able to identify knit and woven fabrics in a practical setting is essential. Here are three simple tests you can perform:

3.1 The Stretch Test: The Most Obvious Clue

This is the easiest and usually the most reliable way to distinguish between knit and woven fabrics:

- Knit Fabric: Gently pull the fabric crosswise (along its width). Knit fabric will stretch easily in this direction. It may also stretch lengthwise, but often to a lesser degree. The amount of stretch will vary depending on the type of knit and the fiber content.

- Woven Fabric: Gently pull the fabric along its length and width. Woven fabric will have very little stretch in either of these directions (unless it contains elastane/spandex fibers blended in). Woven fabric will stretch diagonally, which is known as stretching “on the bias.”

The stretch test is usually definitive. If the fabric stretches significantly, it’s almost certainly a knit. If it has very little give, it’s likely a woven.

3.2 The Wrinkle Test: Checking for Resilience

This test relates to the fabric’s inherent structure and its ability to recover from deformation:

- Knit Fabric: Crumple a small section of the fabric in your hand and squeeze it tightly. Release it. Knit fabric will generally spring back to its original shape with minimal wrinkling. This is due to the inherent elasticity of the looped structure.

- Woven Fabric: Crumple a small section of the fabric in your hand and squeeze it tightly. Release it. Woven fabric will tend to hold the creases and wrinkles more readily. This is because the interlaced structure is less resilient and doesn’t “bounce back” as easily as a knit.

3.3 The Fray Test: Examining the Edges

This test examines how the fabric behaves at a cut edge:

- Knit Fabric: The cut edge of a knit fabric will typically unravel or curl, especially if it’s a weft knit (the most common type for apparel). It doesn’t fray in the same way as woven fabric because the loops tend to pull apart, rather than individual threads separating. The width edge of knits may fray. Manufacturers often apply glue or starch to the lengthwise edges of flat knits to prevent curling.

- Woven Fabric: Woven fabric has a selvedge along its width edge. Selvedge is finished edge. The cut edge of a woven fabric (usually the lengthwise edge, where the warp yarns are cut) will fray easily, with individual threads separating from the weave. This is because the interlaced warp and weft yarns are no longer held together at the cut edge.

3.4 The Visual Test: Examining the Threads

- Knit Fabric: Look very closely at the fabric. Can see the tiny loops or braids.

- Woven Fabric: Look very closely at the fabric. You should be able to see a perpendicular criss-cross pattern, like a tiny grid or checkerboard.

4. Comparing Properties: Knit vs. Woven Characteristics

Here’s a direct comparison of the key properties of knit and woven fabrics:

| Feature | Knit Fabric | Woven Fabric |

| Construction | Interlooping yarns (single yarn or set of yarns looped together) | Interlacing yarns (warp and weft yarns interlaced at right angles) |

| Stretch | High (especially crosswise, in the direction of the weft) | Low (unless elastane/spandex is present); stretches on the bias (diagonally) |

| Drape | Generally good, molds to the body well | Varies greatly depending on fiber, weave, and finish (can be stiff or fluid) |

| Wrinkle Resistance | High (springs back into shape easily) | Low (prone to wrinkling and creasing, requires more frequent ironing) |

| Durability | Varies; some knits are prone to snagging or pilling, but many are durable | Generally high, especially tightly woven fabrics; resists wear and tear |

| Texture | Can range from very smooth (fine jersey) to very textured (cable knit) | Can range from very smooth (satin weave) to very textured (coarse linen or bulky tweed) |

| Ease of Sewing | Can be more challenging due to stretch; requires specific techniques/needles | Generally easier to sew due to stability; standard techniques/needles usually sufficient |

| Fraying | Edges tend to unravel or curl | Edges fray easily unless finished |

4.1 Stretch and Recovery: The Defining Difference

Knit Fabric: The looped structure of knit fabric gives it inherent stretch and recovery (the ability to return to its original shape after being stretched). This is the most significant and easily identifiable difference between knits and wovens. The degree of stretch varies depending on the type of knit (e.g., jersey is stretchier than interlock) and the fiber content (spandex/Lycra adds significant stretch). Knits generally stretch more crosswise (in the direction of the weft) than lengthwise.

Woven Fabric: Woven fabrics, due to their interlaced structure, are generally not stretchy. They have very little give along their length or width. The only natural stretch in a woven fabric is on the bias (diagonally, at a 45-degree angle to the warp and weft). Some woven fabrics do have stretch, but this is because they contain a percentage of elastane (also known as spandex or Lycra) fibers blended in with the other fibers (like cotton or polyester).

4.2 Drape: How the Fabric Falls

Knit Fabric: Knit fabrics generally have good drape, especially those with a looser knit structure (like jersey). This means they tend to mold and conform to the body well, creating a flowing or clinging silhouette.

Woven Fabric: The drape of woven fabrics varies greatly depending on several factors:

- Fiber Content: Silk and rayon wovens often have excellent drape, while linen and hemp tend to be stiffer.

- Weave Structure: Satin weaves drape well; plain weaves can be stiff or fluid depending on the fiber and tightness of the weave.

- Fabric Finish: Some finishes can add stiffness or drape to a woven fabric.

4.3 Wrinkle Resistance: Smooth or Creased?

- Knit Fabric: Knit fabrics are generally highly wrinkle-resistant due to their inherent stretch and recovery. The looped structure allows the fabric to “bounce back” after being crumpled or folded.

- Woven Fabric: Woven fabrics are prone to wrinkling and creasing, and often require ironing to maintain a smooth appearance. The interlaced structure is less resilient and tends to hold creases more readily. Some woven fabrics (like linen) are notoriously prone to wrinkling, while others (like tightly woven twills) are more wrinkle-resistant.

4.5 Texture: From Smooth to Textured

Both knit and woven has texture from Smooth to Textured

4.6 Ease of Sewing: Beginner-Friendly or Challenging?

Knit Fabric: Sewing with knit fabrics can be more challenging than sewing with wovens, primarily due to their stretchiness. This requires specific techniques to avoid puckering, stretching, or damaging the fabric.

- Stretch Stitches: It’s crucial to use stretch stitches when sewing knits. These stitches allow the seam to stretch with the fabric, preventing the stitches from breaking when the garment is worn. Common stretch stitches include:

- Zigzag stitch: A basic stitch available on most sewing machines.

- Stretch stitch (or lightning stitch): A specialized stitch designed specifically for knits, often found on modern sewing machines.

- Overlock stitch (serger): Creates a very strong, stretchy, and professional-looking seam, ideal for knits (but requires a separate machine – a serger).

- Ballpoint or Stretch Needle: Using the correct needle is essential. Ballpoint needles have a rounded tip that pushes the knit loops aside rather than piercing them, preventing runs or snags in the fabric. Stretch needles are designed for highly elastic fabrics like Lycra or spandex.

- Careful Handling: Avoid pulling or stretching the knit fabric while sewing. Let the feed dogs do the work of moving the fabric under the needle. Use plenty of pins or clips to hold the fabric layers together.

- Serger (Overlock Machine): A serger (also known as an overlock machine) is a specialized sewing machine that is particularly well-suited for sewing knits. It trims the seam allowance, sews the seam, and overcasts the edge all in one step, creating a very strong, stretchy, and professional-looking finish. While not essential, a serger is a valuable tool for anyone who sews frequently with knits.

Woven Fabric: Woven fabrics are generally easier to sew than knit fabrics because they are more stable (they don’t stretch).

- Straight Stitch: A standard straight stitch is usually sufficient for sewing most woven fabrics.

- Universal or Sharp Needle: A universal needle is suitable for most woven fabrics. A sharp needle (also called a Microtex needle) is best for very tightly woven fabrics or delicate fabrics like silk, as it has a very sharp point that pierces the fabric cleanly.

- Edge Finishing: It’s absolutely essential to finish the raw edges of woven fabric to prevent fraying. Common edge finishing techniques include:

- Zigzag stitch: A simple and effective way to finish edges on most woven fabrics.

- Overlock stitch (serger): Creates a very clean and durable finish, preventing fraying.

- Pinking shears: Special scissors that cut a zigzag edge, which helps to reduce fraying (though it’s not as effective as stitching).

- Binding: Encasing the raw edge with a strip of fabric (bias tape).

5. Common Types and Uses: Knit and Woven Applications

5.1 Knit Fabric Family

- Jersey Knit: A very common and versatile knit fabric.

- Characteristics: Smooth face (right side) with a slightly textured back (wrong side). Good stretch, soft drape, comfortable to wear.

- Uses: T-shirts, dresses, leggings, underwear, skirts, tops, and many other garments.

- Rib Knit: Characterized by distinct vertical ribs, created by alternating knit and purl stitches.

- Characteristics: Very stretchy, especially in the crosswise direction. Conforms to the body.

- Uses: Cuffs, neckbands, turtlenecks, body-hugging garments, sweaters, hats.

- Interlock Knit: A double-knit fabric (essentially two layers of jersey knit joined together).

- Characteristics: More stable and less prone to curling than jersey. Smooth on both sides. Good drape.

- Uses: Dresses, tops, skirts, children’s wear, higher-quality t-shirts.

- French Terry: Has loops on one side (the back) and a smooth face.

- Characteristics: Absorbent, comfortable, slightly thicker than jersey.

- Uses: Sweatshirts, sweatpants, hoodies, casual wear, robes.

- Sweater Knits: A broad category encompassing a wide variety of knit structures used for sweaters and cardigans.

- Characteristics: Vary widely depending on the specific knit structure (cable knit, rib knit, etc.). Can be chunky and textured or fine and smooth.

- Uses: Sweaters, cardigans, scarves, hats, blankets.

- Ponte Knit (Ponte di Roma): A stable, double-knit fabric.

- Characteristics: Relatively wrinkle-resistant, holds its shape well, more structured than many other knits.

- Uses: Dresses, skirts, pants, jackets (often used for more tailored knit garments).

- Spandex/Lycra: Not a knit type itself, but an elastic fiber that is often blended with other fibers (cotton, polyester, nylon, etc.) to add stretch and recovery to knit fabrics.

- Characteristics: Extremely stretchy and resilient.

- Uses: Added to many knit fabrics to improve their stretch and fit, particularly in activewear, swimwear, and form-fitting garments.

5.2 Woven Fabric World

- Plain Weave: The simplest and most common weave structure. The weft yarn goes over one warp yarn, then under the next, creating a simple, perpendicular over-under pattern. Examples:

- Muslin: A lightweight, inexpensive, loosely woven cotton fabric, often used for making test garments (toiles) or for linings.

- Broadcloth: A smooth, tightly woven fabric, often made from cotton or a cotton blend, with a very subtle horizontal rib. Commonly used for shirts and dresses.

- Quilting Cotton: A medium-weight, plain-weave cotton fabric specifically designed for quilting. Comes in a vast array of colors and prints.

- Poplin: A strong, crisp fabric with a slightly ribbed texture (though the rib is usually less pronounced than in a twill weave). Often used for shirts, dresses, and lightweight jackets.

- Twill Weave: Characterized by a diagonal rib pattern on the fabric surface. This is created by the weft yarn floating over multiple warp yarns, then under one, in a staggered pattern. This creates a diagonal line. Twill weaves are known for their durability. Examples:

- Denim: A strong, durable twill-weave fabric, typically made from cotton, and traditionally dyed with indigo.

- Chino: A twill fabric, often made from cotton or a cotton blend, commonly used for trousers (chinos).

- Gabardine: A tightly woven twill fabric, often made from wool, cotton, or synthetic fibers. Known for its durability and water resistance. Used for suits, coats, trousers, and uniforms.

- Satin Weave: Creates a smooth, lustrous fabric with excellent drape. In a satin weave, either the warp yarns float over multiple weft yarns (warp-faced satin), or the weft yarns float over multiple warp yarns (weft-faced sateen). Examples:

- Satin: A general term for fabrics with a satin weave, often made from silk, polyester, nylon, or rayon.

- Charmeuse: A lightweight satin fabric with a very smooth, shiny surface and a dull back. Often used for lingerie, blouses, and linings.

Other Wovens:

- Linen: Made from the fibers of the flax plant. Strong, breathable, absorbent, and wrinkles easily.

- Flannel: A soft, napped fabric (meaning it has a brushed surface), often made from cotton or wool. Known for its warmth and comfort.

- Corduroy: A fabric with raised vertical ribs (called wales). Typically made from cotton.

- Velvet: A fabric with a dense, plush pile on one side. Can be made from various fibers, including silk, cotton, rayon, and synthetics.

6. Why the Difference Matters: Choosing the Right Fabric

Understanding the distinction between knit and woven fabrics isn’t just academic; it has practical implications for every stage of garment creation, from design to manufacturing to consumer use.

Pattern Instructions: Sewing patterns will always specify whether to use a knit or woven fabric. This is absolutely crucial because the pattern pieces themselves are designed with the specific stretch and drape properties of the intended fabric type in mind. Using the wrong fabric type will almost always result in a garment that doesn’t fit correctly, doesn’t hang properly, and may not even be wearable.

- Knit Patterns: Knit patterns are designed to accommodate the stretch of knit fabric. They often have less ease (extra room) built into the pattern because the fabric will stretch to fit the body.

- Woven Patterns: Woven patterns are designed for stable fabrics that don’t stretch. They typically have more ease built in to allow for movement and comfort.

Garment Function: The choice between knit and woven fabric should also be guided by the intended function of the garment:

- Stretch and Movement: Knit fabrics are the obvious choice for garments that require a lot of stretch and freedom of movement. This includes: Activewear (Leggings, sports bras, yoga pants, athletic tops); T-shirts and other casual tops; Underwear and lingerie; Close-fitting dresses and skirts; Socks and hosiery.

- Structure and Tailoring: Woven fabrics are generally better suited for garments that require more structure and shape, and where a tailored or crisp appearance is desired. This includes:Tailored jackets and blazers; Trousers and slacks; Button-up shirts and blouses; Coats and outerwear; Many types of dresses and skirts.

- Sewing Techniques: As discussed earlier, different sewing techniques, machine settings, and needles are required for knit and woven fabrics. You must adapt your sewing approach to the specific fabric type to achieve professional-looking and durable results.

- Manufacturing Specialization: In the garment manufacturing industry, factories often specialize in working with either knit or woven fabrics, but rarely both. This is because the equipment, expertise, and production processes required for each fabric type are quite different.

Professional Knowledge: A thorough understanding of the distinction between knit and woven fabrics is considered fundamental knowledge for anyone working in the fashion, textile, or garment manufacturing industries. It’s a basic building block for understanding fabric properties, garment construction, and design.

7. FAQs About Knit and Woven Fabrics

7.1 Can I use a woven fabric for a pattern that calls for a knit?

Generally, no. A knit pattern is specifically designed to accommodate the stretch and drape of knit fabric. The pattern pieces will be drafted with less ease (extra room) because the fabric itself will provide some of that ease through its stretch.

If you use a woven fabric (which doesn’t stretch, unless it contains elastane) for a knit pattern, the garment will almost certainly be too tight, will restrict movement, and may not even fit over your head or hips, depending on the design. The seams may also be prone to popping because they won’t be able to stretch with the body’s movements.

7.2 Can I use a knit fabric for a pattern that calls for a woven?

Sometimes, but it requires careful consideration and often adjustments to the pattern. A woven pattern is designed for a stable fabric that doesn’t stretch. If you use a knit fabric, the resulting garment may be too loose, may lack the intended structure, and may drape differently than expected.

If you do decide to use a knit fabric for a woven pattern, you might need to:

- Choose a smaller size: Because the knit fabric will stretch, you may need to go down a size or two to achieve the intended fit.

- Stabilize the knit fabric: In some cases, you might need to interface or underline the knit fabric with a more stable woven fabric to give it more structure.

- Make other pattern adjustments: You may need to adjust seam allowances, ease, or other pattern details to accommodate the knit fabric’s properties.

Using a knit fabric for a woven pattern is generally not recommended for beginners and is best left to more experienced sewers who understand how to adapt patterns and work with different fabric types.

7.3 What is a “stable knit”?

A stable knit is a knit fabric that has minimal stretch. It’s often a double knit, meaning it’s made with two layers of knit fabric interlocked together. This construction gives the fabric more stability and body than a single-layer knit like jersey.

Common examples of stable knits include:

- Ponte knit (Ponte di Roma): A very popular stable knit known for its wrinkle resistance and ability to hold its shape.

- Interlock knit: Another double knit that is smoother and more stable than jersey.

Stable knits are easier to sew than very stretchy knits because they behave more like woven fabrics. They can sometimes be used for patterns that call for wovens, but it’s still important to check the pattern requirements and the fabric’s stretch percentage. Even stable knits have some stretch, so adjustments may still be necessary.

7.4 Do all woven fabrics fray?

Yes, all woven fabrics will fray at cut edges unless the edges are finished in some way. This is because the interlaced warp and weft yarns are no longer held together at the cut edge and can easily unravel.

The degree of fraying can vary depending on the weave structure and the fiber content. Loosely woven fabrics tend to fray more easily than tightly woven fabrics.

To prevent fraying, you must finish the raw edges of woven fabrics using one of the following methods:

- Serger (Overlock Stitch): This creates a very clean and durable finish, encasing the raw edge with thread.

- Overlock stitch (on a regular sewing machine): Many modern sewing machines have an overlock stitch that mimics the finish of a serger.

- Zigzag stitch: A simple and effective way to finish edges on most woven fabrics.

- Pinking shears: Special scissors that cut a zigzag edge, which helps to reduce fraying (though it’s not as effective as stitching).

- Binding: Encasing the raw edge with a strip of fabric (often bias tape).

7.5 Why do some woven fabrics have stretch?

Some woven fabrics have stretch because they contain a small percentage of elastane fibers (also known as spandex or Lycra) blended with the other fibers (like cotton, polyester, or linen). Elastane is a highly elastic synthetic fiber that can be stretched significantly and then return to its original shape.

Even a small amount of elastane (e.g., 2-5%) can add a noticeable amount of stretch and recovery to a woven fabric. This is often done to improve comfort, fit, and wrinkle resistance, particularly in garments like jeans, trousers, and fitted shirts. This stretch is usually in weft direction.

8. My Pack Love – Providing Service for Clothing Labels

My Pack Love specializes in providing high-quality, custom labels, tags, zipper bags, and poly mailers for clothing brands. With over 8 years of experience in the garment industry, particularly in processing labels and tags and zipper bags and poly mailers, we understand. Visit our website at mypacklove.com to explore our services and contact us for a quote or consultation.

Read more:

Understanding the difference between knit and woven fabrics is a fundamental skill for anyone involved in sewing, fashion design, or the textile industry. These two primary fabric types are constructed differently – knits are made by interlooping yarns, while wovens are made by interlacing yarns – and this difference in construction leads to significant variations in their properties.

Knits are generally known for their stretch, drape, and wrinkle resistance, making them ideal for garments that require comfort and movement. Wovens are typically more stable, durable, and easier to sew, making them suitable for structured garments and items that need to hold their shape.