Basic Sewing Terms: An A-Z Glossary for Beginners

Navigating the world of sewing terminology can initially feel like learning a new language, potentially causing some overwhelm for beginners. This article serves as a clear, straightforward guide designed to demystify these essential sewing terms.

Presented in an easy-to-reference format, this resource will help build your crafting vocabulary. By understanding this fundamental sewing knowledge, you’ll gain confidence, interpret sewing patterns more accurately, and embark on your sewing projects with greater success.

1. Understanding the building blocks: Key categories of sewing terms

Before diving into the list, understanding how sewing terms fit together can be helpful. Grouping concepts into categories provides context. Key areas include:

- Fabric terms: Describing the material itself (grain, bias, selvage).

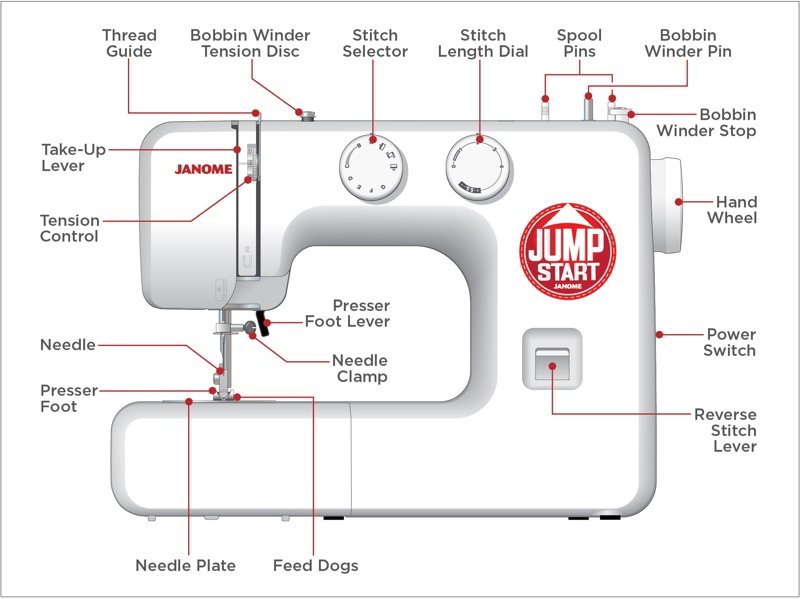

- Sewing machine parts: Components of your machine (bobbin, feed dogs, presser foot).

- Pattern markings: Symbols and lines on your pattern pieces (cutting line, grainline, notches).

- Stitch types & seams: How fabrics are joined (backstitch, French seam, zigzag stitch).

- Sewing techniques: Actions performed during construction (basting, clipping, pressing).

Consider these categories as the foundational concepts within garment construction. This brief overview offers structure before exploring individual definitions.

2. A glossary of essential sewing terms

2.1 Appliqué

Appliqué involves stitching a piece of fabric (often a decorative shape) onto the surface of another larger piece of fabric. The purpose is primarily decorative, adding visual interest or embellishment to a garment or project. Common methods include securing the shape’s edges by hand with a blanket stitch or using a machine zigzag stitch.

Why it matters: A versatile decorative technique to personalize projects.

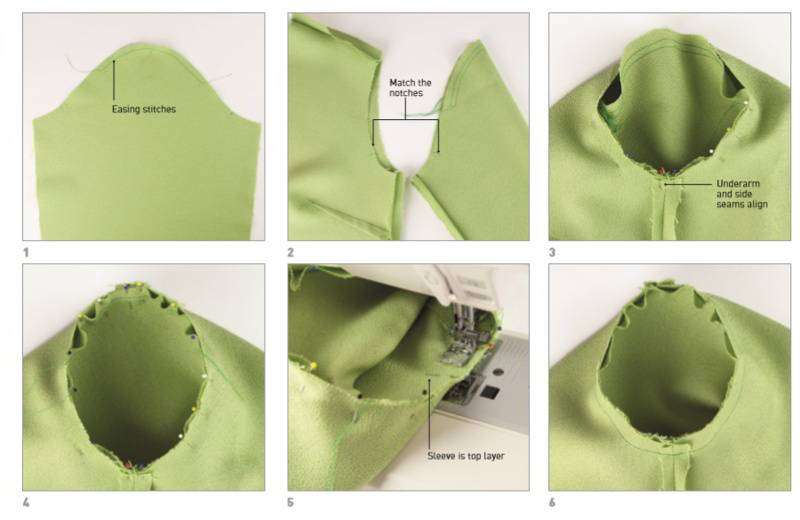

2.2 Armscye

The armscye (or armhole) is the opening in the bodice (the upper part of a garment) where the sleeve is attached.

Why it matters: Correctly shaping and sizing the armscye is crucial for properly fitting sleeves and ensuring comfortable movement.

2.3 Backstitch / back tack

This refers to sewing backward for a few stitches at the beginning and end of a seam, directly over the forward stitches, before continuing forward again. Its essential purpose is securing the seam.

Why it matters: Backstitching locks the threads in place, preventing seams from unraveling during wear or washing. A fundamental step for durable construction.

2.4 Bar tack

A bar tack consists of several small, concentrated reinforcement stitches, often created using a narrow zigzag stitch. Its purpose is to strengthen areas subjected to high stress or strain. Examples include the corners of pockets, ends of buttonholes, and attachment points for belt loops.

Why it matters: Adds significant durability to vulnerable points on a garment, preventing tears.

2.5 Basting (or tacking)

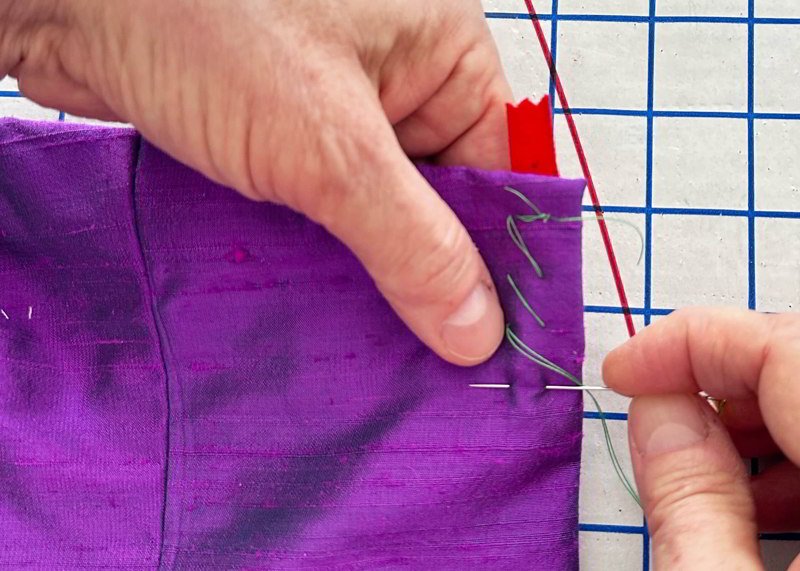

Basting involves creating temporary stitches to hold fabric pieces together. These stitches are typically longer than standard stitches and are easily removable. Methods include hand sewing with a running stitch or using a long stitch length setting on a sewing machine (often with reduced upper tension for easier removal). Basting is used for holding pieces temporarily for fitting checks, keeping slippery fabrics aligned, or preparing an edge for gathering.

Why it matters: Provides a temporary hold without committing to a permanent seam, allowing for adjustments and making complex sections easier to manage before final stitching.

2.6 Bias

The bias refers to the diagonal direction across woven fabric, precisely at a 45-degree angle to the lengthwise grain (warp) and crosswise grain (weft), which run parallel and perpendicular to the selvage (the finished edge of the fabric), respectively. Woven fabric exhibits its maximum stretch along the bias.

Why it matters: Understanding the bias is key for creating garments with good drape, fitting fabric smoothly around curves, and making bias tape. Utilizing the bias stretch allows fabric to conform without puckering.

2.7 Bias tape / bias binding

Bias tape consists of fabric strips cut on the bias (the 45-degree angle). Because fabric cut this way is stretchier, bias tape is ideal for neatly finishing curved edges like necklines and armholes. The stretch allows the tape to conform smoothly around the curve without bunching or puckering. Bias binding can be purchased pre-made or created from coordinating or contrasting fabric.

Why it matters: Essential for professionally finishing curved raw edges, providing both a neat appearance and structural support.

2.8 Binding

Binding refers to the technique of encasing a raw fabric edge with a separate strip of fabric (like bias tape). This finishing method creates a clean edge.

Why it matters: Produces a neat, durable, and often decorative edge finish, concealing the raw fabric edge to prevent fraying.

2.9 Blind hem

A blind hem is a type of hem finish where the stitches are barely visible on the right side (the public side) of the garment. This technique creates a clean, professional look often desired for trousers, skirts, and dresses. A blind hem can be sewn by hand using specific stitches or by machine using a specialized blind hem presser foot and stitch setting.

Why it matters: Achieves a high-quality, almost invisible hem finish suitable for many types of garments.

2.10 Bobbin

The bobbin is a small spool that holds the lower thread in a sewing machine. This thread loops with the upper thread (from the main spool) to form a lockstitch.

Why it matters: Correctly winding the bobbin and inserting the bobbin into its case (and then into the machine) according to the machine’s manual is crucial for proper stitch formation. Issues with stitch quality often relate back to the bobbin.

2.11 Bodice

The bodice refers to the part of a garment that covers the body from the shoulders down to the waist. In dresses or tops, this section forms the main upper part.

Why it matters: A fundamental garment piece; understanding this term helps in pattern instructions and garment construction discussions.

2.12 Casing

A casing is a channel or tunnel created by folding over an edge of fabric and stitching near the fold, leaving the channel open at one or both ends. The purpose is typically to enclose elastic or a drawstring, allowing for gathering or cinching. Common examples are found in waistbands of skirts or pants, sleeve cuffs, or bag openings.

Why it matters: Provides a functional way to incorporate elastic or drawstrings for fit adjustments or closures.

2.13 Clip / clipping curves

Clipping involves making small, straight cuts (snips) into the seam allowance (the fabric between the stitching line and the raw edge) of an outward (convex) curve, stopping just short of the stitching line. For inward (concave) curves, small V-shaped wedges (notches) are cut out of the seam allowance. The purpose is to allow the seam allowance to spread (for outward curves) or compress (for inward curves) when the piece is turned right side out, enabling the seam to lie flat and smooth.

Why it matters: Absolutely essential for achieving smooth, professional-looking curves on collars, necklines, facings, and other shaped pattern pieces. Prevents puckering and bulk.

2.14 Cord

Cord refers to twisted fibers, thicker than string but thinner than rope. In sewing, cord might be used inside piping to give structure or sometimes threaded through a casing as a drawstring.

Why it matters: Used as a component in certain decorative trims (piping) or functional elements (drawstrings).

2.15 Crosswise grain

The crosswise grain refers to the direction of threads running perpendicular to the selvage (the finished edge of the fabric) in woven fabric. These are the weft threads. Fabric typically has a slight amount of give or stretch along the crosswise grain, more than the lengthwise grain but less than the bias.

Why it matters: Important for fabric layout according to pattern instructions, as different grains have different stretch and drape properties.

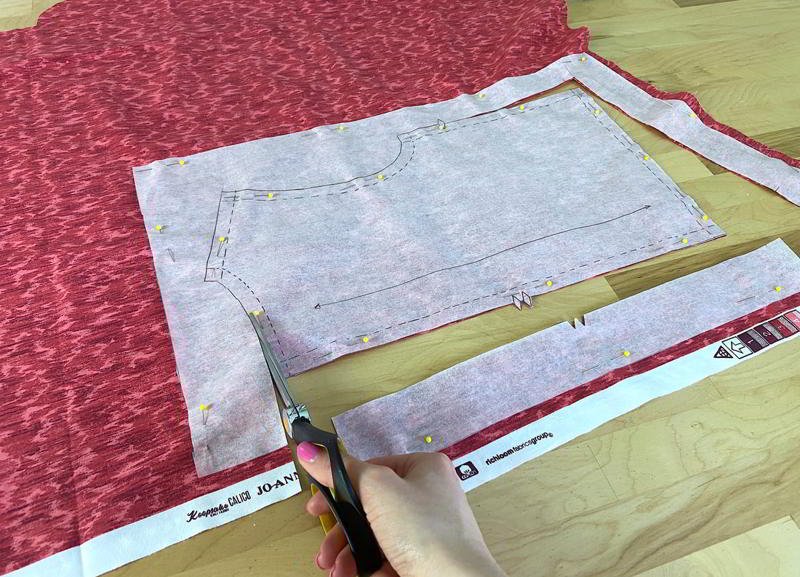

2.16 Cutting line

This is the specific line indicated on a pattern piece that you must cut along. Patterns often include multiple sizes, so the cutting line will vary depending on the chosen size, usually indicated by different line styles (solid, dashed, dotted).

Why it matters: Cutting accurately along the correct line for your size is fundamental for ensuring the finished garment fits properly.

2.17 Cut on fold

An instruction found on pattern pieces indicating that one edge of the pattern piece should be placed exactly along the folded edge of the fabric before cutting. Do not cut along this folded edge. When the fabric is unfolded after cutting, a full, symmetrical piece is created without a seam down the center. Frequently used for pieces like bodice fronts, backs, or facings where symmetry is desired.

Why it matters: Ensures symmetrical pattern pieces are cut efficiently and eliminates the need for a center seam.

3. Common questions about basic sewing terms

3.1 What’s the real difference between grainline and bias?

Grainline refers to the direction of threads in woven fabric: lengthwise (parallel to the selvage, minimal stretch) and crosswise (perpendicular to selvage, slight stretch). The bias is the diagonal direction (45 degrees to the grainlines) where woven fabric has the most stretch. Pattern instructions use grainline markings to ensure pieces hang correctly, while the bias is utilized for drape or finishing curves.

3.2 Is pressing really that important while sewing?

Yes, pressing seams as you sew is crucial for a professional finish. Pressing sets stitches, flattens seams, and shapes the garment. Skipping pressing often results in bulky, messy-looking seams and makes subsequent steps more difficult and less accurate. Use an iron temperature appropriate for your fabric and press seams open or to one side as pattern instructions direct.

3.3 What is a seam finish, and do I always need one?

A seam finish is any technique used to treat the raw edge of the seam allowance inside a garment to prevent fraying. Common methods include serging (overlocking), using a zigzag stitch on a regular machine, pinking shears (less durable), or enclosing the seam (like a French seam).

While not always strictly necessary for fabrics that don’t fray much or for test garments, finishing seams significantly improves the durability and appearance of most garments, especially those that will be washed frequently.

3.4 My pattern doesn’t state the seam allowance. What should I use?

While most commercial patterns specify the seam allowance (often 1.5cm or 5/8 inch for dressmaking), if missing, 1.5cm (5/8 inch) is a common default for garments. However, check all pattern pieces and instructions thoroughly first. For crafts or quilting, a 1/4 inch allowance is more typical. Consistency is key; use the same allowance throughout unless instructed otherwise.

3.5 Patterns have so many lines and symbols. What are the most important ones to understand?

Key markings include:

- Cutting lines: Indicate where to cut for your size.

- Grainline arrow: Must be parallel to the fabric’s lengthwise grain/selvage.

- Notches: Diamond or triangle shapes used to align adjoining pieces accurately.

- Dots/squares: Indicate points for matching, like dart placements or pocket positions.

- Fold line: Shows where to place the pattern edge on a fabric fold.

Understanding these markings is essential for accurate cutting and assembly.

Read more:

Mastering sewing vocabulary is a significant step towards boosting your sewing confidence and achieving successful project outcomes. This glossary provides a solid foundation for understanding the essential terms encountered in patterns and instructions. Remember that practice is invaluable; don’t hesitate to refer back to these definitions as needed.

The best way to solidify your understanding is to apply this knowledge. Consider starting a simple beginner project or dedicating time to learning the basic functions of your sewing machine. As you continue your sewing journey, these terms will become second nature. For further sewing resources, tutorials, or quality supplies, exploring dedicated sewing websites or suppliers can provide additional support.